Automotive

Research Laboratory

Department

of Mechanical Engineering

G01D

and 257 Fluor Daniel Engineering Innovation Building

Facilities:

The Automotive

Research Laboratory has over 300 sq ft of floor space supporting research on

internal combustion engines, automotive steering systems, and electro-hydraulic

systems. The Automotive Cells have the following equipment available to support

research: SuperFlow 901 engine dynamometer, International Dyno Corporation

Model 500 dynamometer, Electro-Mechanical Micro-Dyn 35 dynamometer, Interro

Systems emission gas analyzer, assorted engines (3.8L V6, 4.6L V8, Kohler

674cc, Briggs & Stratton 627cc, Two Stroke), scale thermal test stand,

Motec M48 development controller, production controllers, various Omega

sensors, and assorted engine sensors and actuators. The Steer-by-Wire Station

features a multi-functional rack and pinion steering system for

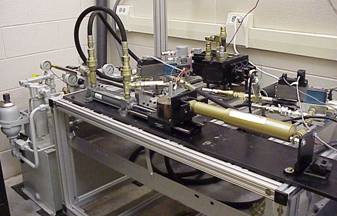

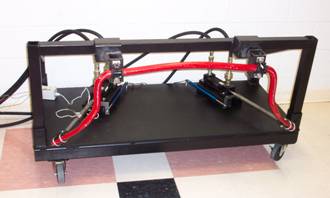

hardware-in-the-loop testing and driving simulator studies. The Hydraulics

Bench is equipped with a Bosch hydraulics pump, two Bosch servo-proportional

valves, a Moog servo-valve, assorted sensors, and hydraulic cylinders and motor

for chassis roll control investigations. To support this experimental

equipment, the laboratory has three high-end personal computer workstations and

a QNX real-time workstation used for data acquisition and control with

"servo-to-go" I/O board. The Matlab/Simulink software package with

Real Time Workshop and AMESim multi-domain modeling tools are available.

Two

and four stroke engines mounted on dynamometers for design, control, and

emissions studies

As needed, experiments may be performed in the Robotics &

Mechatronics Laboratory which features a variety of instrumentation, tools, and

similar data acquisition and control hardware/software. Research team members

can complete their experimental builds through the Department of Mechanical

Engineering Machine Shop with supporting technicians, the

Active

torsion bar hydraulic experimental system to minimize the vehicle’s body roll

angle