42 Volt Technology

by Numair Mazgaonkar, Clemson Automotive Engineering Graduate Student

- Basic Description

-

Today vehicles come with a large number of accessories like the infotainment sytems, climate controls, passenger comfort features like the heated seats etc. and many safety systems. Also, there are a large number of electronic sensors and actuators in these automobiles. And technological advancements in conversion of hydraulic/mechanical systems to electronic sytems are making electrical system in vehicles more and more complex. All this is increasing the load on the 12V car battery, which one day will eventually be unable to cope with the power demand of the increasing number of electrical and electronic systems in the vehicle. Even today some high end vehicle manufacturer are facing this problem of electric energy. A possible solution to this is the 42 Volt battery technology. The 12V batteries which are used in today's car are charged by a 14V supply. So, 42V is actually three times 14V, i.e the voltage of the battery will be 36V, it will be charged by 42V supply.

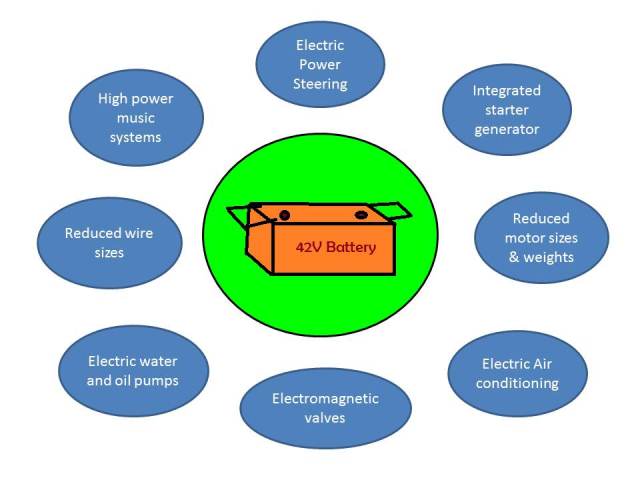

The 42-volt technology will reduce weight, improve fuel economy, permit the replacement of many mechanical parts with electrical ones, power all sorts of new gizmos and most of all, it will improve efficiency for all automotive electrical devices.It will also reduce the complexity of the current 12-volt electrical systems.

Uses with 42V technology

Advantages of 42 Volt technology

- (1) Alternators consume alot of fuel for their operation. With 42V technology, the requirement of fuel by the alternators will reduce to one-third.

- (2) The weight of the wiring harness will reduce due to the reduced diameter of the wire because of the high voltage. This in turn will make the harness more flexible.

- (3) With increase in voltage, there is almost a linear decrease in weight of solenoids. So, for motors a weight reduction of almost 20% is possible.

- (4) Current technologies, like the power windows, power seatbelts, power hatch-back lifts will have reduced size and weight and more efficiency.

- (5) More power will be available for multimedia devices like the music sytems, GPS, communication systems etc.

- (6) Pumps will have reduced size and hence good packaging.

- (7) Electromagnetic valves in camless engines which employ the use of solenoids and magnetic systems require alot of electric power for their operation will work more efficiently with the 42V system and increase engine efficiency.

- (8) Electrically driven systems like electrical active suspension, electric water and oil pumps and electric air conditions can be driven directly by electric energy of the 42V battery will reduce the load from the engine.

- (9) With 42V technology, additional power can be supplied to electrically heated catalytic converter which would useful in cold environments.

Batteries

- Lithium-ion batteries are mostly proposed for 42V technology as these batteries have been tested for one million cycles of charging and discharging. They also have a good combination of specific power and specific energy. Expected life of these batteries is clamied to be around ten years. Another battery which was developed by Johnson controls laboratory is a 36V battery using a thin metal foil for more power. Lightweight materials were used to reduce the weight of the 36V battery.

- Inspite of the potenitial advantages of the 42V technology, the automotive industry is not sure on the profit aspect of the system because of the following reasons:

- (1) Economic hurdles: Shifting from 12V to 42V technology means that all the electric components will need to be changed and upgraded, or an additional circuitry will be required to incorporate the same old components. Also, production and service of these batteries will be costly due to the completely new technology and so high initial investment will be required.

- (2) Technical hurdles: Jumpstarting a 42V technology run vehicle by an 12V version can cause permanent damage to the 12V system. In todays vehicles, mostly tungsten filament bulbs are used. A 42V technology means that the tungsten filaments need to be thinned out in order to produce the same luminosity. This is a serious challenge for OEMs.

- As voltage levels rise, the higher voltage can more readily jump the air gap between electrical conductors and "arc." The energy in the arcs of 42-volt system is much higher than that in a 12/14-volt systems. The solution to this is a lot of subtle part redesign that have to be done to prevent arcing. But safety concerns due to arcing may just be a myth. According to the tests conducted by the German standard committee voltages below 60V are not harmful. And as the voltage of the 42V technology is below that level, there is no safety problem. But due these many problems many automotive companies and suppliers are looking for other alternatives. Now-a-days, hybrids with 250V plus batteries and inverters run the starter motor readily, which have blown away the requirement of 42V batteries.

- Manufacturers

- Shenzhen Mottcell Battery Technology, Dongguan Greenway Battery, Optimum Battery.

- For More Information

- [1] Jump starting 42V technology vehicles, www.docstoc.com, Aug. 25, 2010.

- [2] 42-Volt autos, caraudiomag.com, Feb 24,2009.

- [3] Whatever Happened to the 42-Volt Car popularmechanics.com, Oct. 01, 2009.

- [4] Advanced Battery Diagnosis for Electric Vehicles Norwegian University, June 2008.

- [5] 42V Battery test Manual, nrel.gov, April, 2003.

- [6] Stretching 12V Electrical Power Limits, SAE, Oct. 6, 2003.

- [7] 42V Powernet architecture standards, University of Alabama

- [8] Battery statistics, Battery University

|