Historically, diesel engines have used

the unit

injection system and the distributor/inline pump system. These older

systems had two main disadvantages: Firstly, they were cam-driven and

as a result the maximum pressure for fuel injection was only achieved

at high engine speeds. Secondly, they were limited in the number of

injections that they could deliver per combustion cycle. The

common-rail injection diesel systems build upon direct-injection

technology which allows fuel to be injected

directly into the combustion chamber. Common-rail injection systems use

a rail to store

the fuel at pressures in excess of 2,000 bar. This rail is shared

between all cylinders, hence the name common-rail. The common rail

allows a steady high-pressure supply of fuel independent of engine

speed. The transfer pump is electronically activated to maintain the

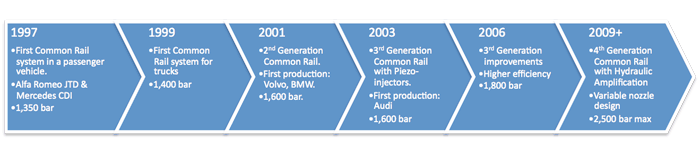

optimal pressure in the rail. Early generations of common-rail

injectors used magnetic solenoids to control the injection of fuel into

the cylinders. The latest generation of common-rail injectors use

piezoelectric inline actuators to control fuel injection. These new

actuators use hundreds of piezo-crystal wafers which expand very

rapidly when a current is applied. Piezoelectric inline actuators can

be integrated very close to the injector jet needle, providing

friction-free movement. These injectors allow for much more precise

fuel-injection times with shorter response times, as well as improved

atomization of the fuel.

Common Rail diesel injection systems have

several main advantages over older fuel injection systems. The high

pressure fuel supply from the rail allows for the fuel to be injected

quickly and at high pressure into the cylinders. This allows the

electronic diesel control unit (EDU) to very accurately control the

fuel injection. Such accurate control allows for up to 5 fuel

injections per combustion stroke ("pilot", "pre", "main", "after", and

"post" injections). The "pilot" injection, which occurs before ignition

allows for good fuel-air mixture. The subsequent "pre" injection

shortens the delay in the main injection, drastically reducing NOx

gases, vibrations and other noise. The "after" injection occurring

immediately after the "main" injection ensures that all particle matter

is burned. Finally, the "post" injection allows for control of exhaust

gas temperature, increasing after-treatment efficiency.

The overall result of using advanced

common rail diesel injection systems is an engine that operates more

efficiently, and is capable of outperforming it's gasoline-powered

counterpart. Virtually all previous downsides of operating a diesel

engine, such as noise, weak performance, vibrations and particle

emissions have been eliminated with common rail direct injection

diesel engine technology.

Common Rail Engine Names by

Manufacturer:

Audi: TDI

BMW: D-engines

Daimler: CDI

Fiat Group: JTD

Ford: TDCi Duratorq and Powerstroke

GM Opel/Vauxhall: CDTi and DTi

GM Daewoo/Chevrolet: VCDi

Honda: i-CDTi

Hyundai/Kia: CRDi

Land Rover: TD5

Mazda: CiTD

Mitsubishi: DI-D

Nissan: dCi

Peugeot: HDI or HDi

Renault: dCi

Subaru: TD

Toyota: D-4D

Volkswagen: TDI

Volvo: D and D5