Electronic Controls in Turbochargers

by Ninad Alulkar, Clemson Automotive Engineering Graduate Student

-

A turbocharger is a forced induction system, in which air is compressed before flowing into an internal combustion engine. The advantage of compressing the air is that more air can be forced into the engine cylinders, to burn more fuel and obtain more power from each combustion cycle. Turbocharging improves the power to weight ratio of the vehicle; thus a turbocharged engine produces more power than an engine of same capacity without turbocharging.

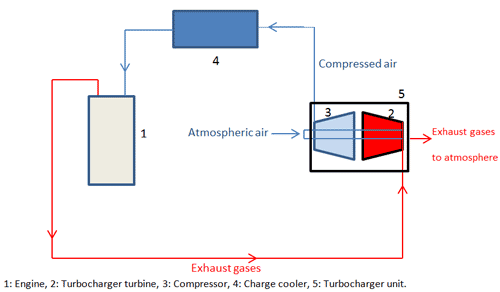

A turbocharger consists of a turbine and a compressor (centrifugal), which is driven by the turbine. The turbine and compressor are mounted on the shaft. The turbocharger is normally bolted to the engine exhaust manifold. The high velocity and high pressure exhaust gases from the exhaust manifold spin the turbine blades at speeds on the order of 150,000 rpm. The turbine spins the compressor blades, creating suction at the eye of the compressor. The atmospheric air is drawn by the compressor through a filter. The air is compressed in the centrifugal compressor to 20.7-22.7 psi. The air is then sent to the engine cylinders after passing through a charge cooler. The charge cooler helps to reduce the specific volume of air entering the engine cylinder.

Another important part of a turbocharger is the wastegate. The wastegate is a valve that allows the engine exhaust gases to bypass the turbine. This slows down the turbine blades, preventing build-up of excessive forces on turbocharger bearings. Thus, the wastegate regulates the speed of the turbine blades by controlling the amount of gases passing over the turbine blades. Turbochargers are employed mostly in sports cars, performance cars and heavy duty engine applications.

- Boost gauge

-

A boost gauge is nothing but a pressure gauge that indicates the turbocharger boost pressure or manifold air pressure for an engine. The distinguishing factor between an air pressure gauge and a boost gauge is that the boost gauge measures pressure above a set value. This value is normally the value of atmospheric pressure, which is 14.7 psi. Boost gauges use manifold air pressure sensor to sense pressure.

Boost gauge allows the driver to perceive when the maximum power can be achieved, analogous to a tachometer. The boost gauge also shows excessive pressure developed in the manifold. This enables the driver to operate the electronic boost controller to reduce pressure in the manifold. The boost gauge is commonly mounted on the dashboard of the vehicle.

- Electronic Boost Controller

-

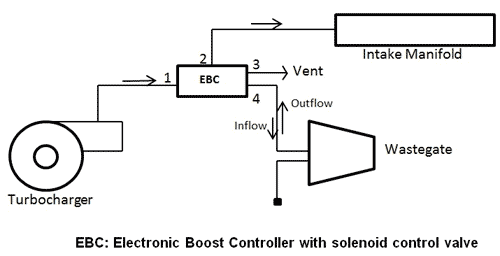

The electronic boost controller is the best way to control the boost pressure in a turbocharger. The boost controller uses a manifold pressure sensor and a solenoid valve, which is connected to the manifold and the wastegate actuator. The solenoid valve operation is controlled from the ECU. The principle of electronic boost controller is based on control of solenoid valve, to reduce pressure (when pressure exceeds desired value) in manifold, by bleeding air to atmosphere. The regulated pressure, results in improved performance of the engine. An electronic boost controller allows the driver to set desired value of boost level.

The control over the solenoid valve may be open loop or closed loop. Closed loop systems depend on feedback from the manifold air pressure (MAP) sensor, to maintain a set value of boost pressure. Open loop configurations do not use MAP sensors, but have a set output, which is determined from input parameters like throttle position and engine speed.

Today, stepper motors are used in conjunction with solenoid valves. Stepper motors prove fine control over boost pressure and solenoids provide coarse control. Typically 2-port solenoids with PID controllers are employed on stock turbocharged cars.

- Manufacturers

- GReddy, HKS, Turbosmart, AEM, Gizzmo

- For More Information

- [1] Turbocharger, Wikipedia.

- [2] Boost Controller,Wikipedia.

- [3] Boost Gauge, Wikipedia.

- [4] HDi SBG-D Boost Gauge, YouTube, Aug. 11, 2008.

|