TPRS or Tire Pressure Regulation System allows the driver to inflate/deflate tires while the vehicle is in motion. This system uses the information provided by Tire Pressure monitoring system to change the air pressure in one tire or all the four tires. When tires are 20% under inflated, tire life and fuel economy can be reduced by 30% and 3% respectively. Vehicle handling characteristics are also adversely affected due to low tire pressures.

Even though, it is not very common in present automobiles but it is being used on commercial and military trucks for quite a long time. These vehicles have to deal with rough and demanding terrains, like deserts, surfaces covered with snow, etc. This system provides the flexibility to the vehicle to adapt to the different terrains by varying the tire pressure, for example a vehicle driving on snow requires more contact with the surface, so the tire pressure can be reduced and under normal operations tires can be inflated again. Other applications also include, pulling a heavy load out of an incline at slow speeds, and crawling out of soft dirt.

This system is generally classified as:

- 1) Direct TPRS: These do not require any external monitoring systems, and would be contained within the tires.

- 2) Indirect TPRS: First gathers information from TPMS and then regulates the pressure as per the action taken by the user.

History: Since 1960, Czech Military heavy trucks are equipped with Central Tire Inflation System to maintain pressure in the tires even after multiple punctures made by bullets.

U.S Military has been using Chevrolet Blazers and Pick-ups since 1980, which have TPRS to maintain the pressure as per the requirements of various demanding terrains.

Presently, commercial vehicles do not get company-fitted TPRS/CTIS but it is readily available for big trucks/SUVs, like Hummer as after-market system.

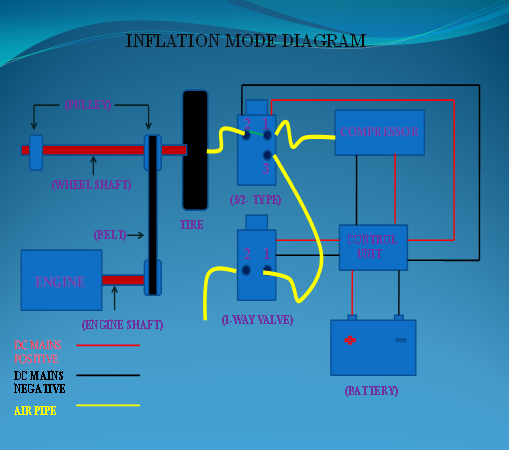

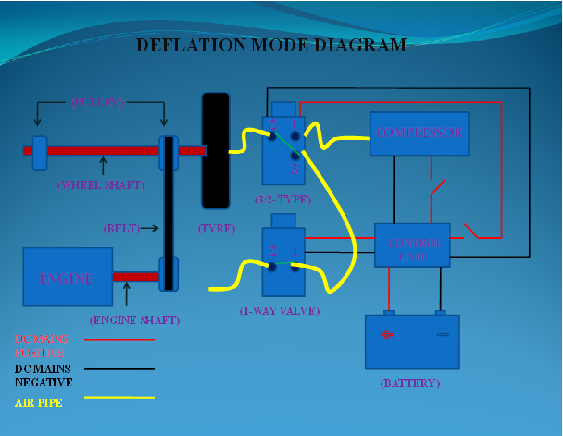

Working: The basic requirement of this system is compressed air to fill in the tires. To achieve that various alternatives have been proposed, e.g. using a peristaltic pump, high pressure reservoirs on wheels, centralized compressor system, centralized tire inflation controller, tire pressure regulating system using an engine with turbocharger, etc. The other important component is Rotary Union, which has one stationary end connected to the compressor and one rotating end connected to the tire valve. When TPMS senses a pressure drop, it informs the user by warning signals. So the user using the controls on the dashboard starts the TPRS which compares the optimum pressure level to the present pressure level and connect the compressor to the rotary union of the respective tire through solenoid valves. As soon as the pressure reaches the desired value solenoid valve stops the flow of air into the tire.

This system is still in development phase, and requires addressing few important issues, like how to generate compressed air in a vehicle without compromising with the vehicle efficiency, and cost-effectiveness of the system.