Seatbelt Pretensioning Systems

by Craig Stanfill, Clemson Automotive Engineering Graduate Student

- Basic Description

-

The proper use of a seatbelt during an automobile crash can in many ways reduce the risk of injury to the occupants and in almost all cases save lives. To improve upon the basic functionality of the seatbelt as a restraint system, a pre-tensioning system has been integrated. When a crash pulse is detected by continuous monitoring of the vehicle acceleration, a signal is sent to the system to apply tension to the seatbelt. The result is removal of any slack in the belt and thus restraining the occupant securely to the seat. Excess slack in the belt can allow the occupant to move in a crash and collide with interior components resulting in injury. This form of passive safety acts in many ways to the activation of the airbag deployment system and in some cases the two are coupled under the same overall system.

There are three main types of seatbelt pre-tensioning systems which are in the forms of mechanical or electronic controlled systems. The most common mechanical system relies on a cam engagement resulting from a sudden acceleration change; the inertia of the mass of the engagement wheel then develops the locking and tensioning forces. The fault to this system is that any sudden jolt on the belt could cause engagement, therefore, a false lock-up can be found annoying to the occupant that is simply putting on their seatbelt. To avoid such instances the two electrically controlled systems are better served, namely, electric motor actuated and pyrotechnic actuated.

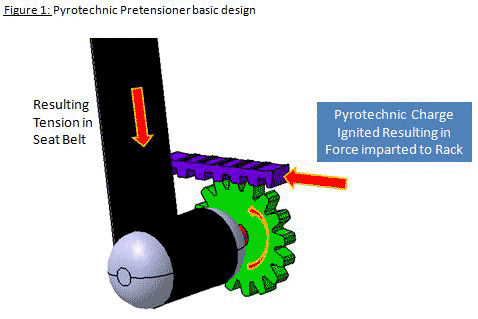

The pyrotechnic actuated is the most common electrically controlled pretensioner to date. The triggering of the device is based on the data from the vehicle accelerometer sensor. When a crash pulse is detected an electric signal is sent to the device. In most common designs the pyrotechnic charge is then activated which develops an expansion of gas in a piston cylinder which then imparts a force onto a rack and pinion system engaging the spool of the seatbelt. The result is an increase in tension to the belt and a locked position. Provided in the figure below is an illustration of this system.

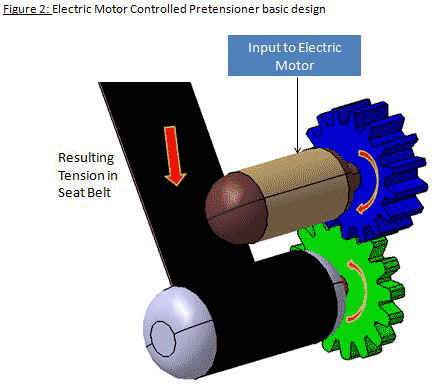

The electric motor actuated system is controlled in the same manner as the pyrotechnic. However, in most common designs a gear connected to the electric motor engages the belt spool. The motor is then controlled to first remove the slack in the belt and provide the torque to the gear equating to the prescribed tension. The figure below indicates the basic functionality of this system.

In latest designs a load or force limiter is integrated to mediate between the pretensioner resulting forces. This aids in reducing the risk of injury to the occupant from the belt itself. In common designs a tensional spring is the load limiting component.

Further integration is being developed by TRW Automotive to integrate the seat belt tensioning system to active safety systems such as the electronic stability control or active brake assist. In this way the seat belt can be pre-tensioned even prior to the crash pulse occurring. The methodology is to use information from distance sensors to determine the vehicle proximity relative to other traffic/objects and the brake pedal application by the driver to determine if a crash is inevitable. The system is now being called Active Control Retractor (ACR). [2]

- Sensors

- Seat Occupant, Accelerometer, Brake Pressure, Distance

- Actuators

- Pyrotechnic, Electric Motor

- Data Communications

- High speed CAN Bus network.

- Manufacturers

- TRW, Autoliv, Takata, Denso, Bosch, STMicroelectronics

- For More Information

- [1] Integrated Seatbelt System, BMW website.

- [2] Active Seatbelt Retractor, autobeatinsider.com, July 25, 2011.

- [3] Seatbelts,Tom Harris, How Stuff Works.com.

- [4] Seatbelt Pretensioner, Autobytel.com, April4, 2008.

- [5] High-Tech Vehicle Safety Systems Seat Belt Pretensioners, CARSP.ca

- [6] Pre-Tensioner and Force Limiter - Toyota New Zealand, YouTube, July 4, 2011.

|