DIY Engine Control Management

by Joel P. Dixon, Clemson Electrical Engineering Student

- Basic Description

-

Newer vehicles have very sophisticated engine control modules (ECM) that control the fuel, injectors, throttle, etc. in the engine. Any ECM is basically a microcontroller that reads values from the engine's sensors, calculates how much fuel and air should go into the engine (as well as possibly some other things, such as spark timing), and then controls the actuators to make it happen. Newer technologies have allowed modern ECMs to provide fine engine control as well as different behaviors (i.e. economy mode vs sports mode). However, there are millions of older cars that are still driven daily or used as race cars on the track that still have very basic engine control (for instance, I drive and autocross race a 1990 Honda CRX with very basic Electronic Fuel Injection). It is now possible to upgrade the ECM on these older cars with do-it-yourself (DIY) engine controllers. This allows you to take advantage of an older car's body, suspension, and engine without the limitations of the older engine management.

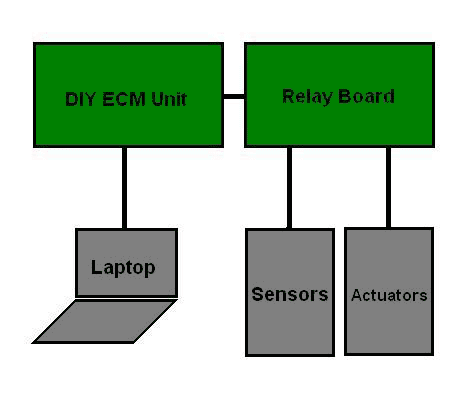

Aftermarket ECMs consist of several basic building blocks:

- ECM Unit - This unit contains the microcontroller that actually reads values from the sensors and sends commands to the actuators. This microcontroller is much faster than the one in the stock ECM being replaced (in the case of older vehicles). This allows it do many more calculations during each engine cycle.

- Relay Board - This board contains relays (and stepper motor drivers) that are driven by the ECM Unit. The relays and motor driver circuits control the actuators without pulling too much current from the ECM Unit.

- Laptop - The laptop or net book is used to program the ECM Unit. Configurations can be loaded into the ECM Unit and the laptop can be removed to drive the vehicle. Alternatively, the laptop can be mounted in the car, and different configurations can be loaded on the fly. So for example, a car could be driven to a track with a normal economy mode enabled, then the ECM Unit can be reprogrammed to enter a more aggressive sport mode while the car is racing on the track.

- Sensors and Actuators - These are the same sensors and actuators currently used in the vehicle. These are not changed at all, they are just controlled in a different way.

These DIY ECMs work just like the stock ECMs do. Values are read from the sensors to determine the current state of the engine (fuel, air, cam/piston position). These values are then used to figure out what to do next. Fuel and air amounts are calculated based on a set of equations that are burned into the microcontroller's firmware. The flexibility of the system comes from being able to to change these equations and constants that are used to run the engine. Since the microcontroller is much faster than older stock ECM's, these calculations can be done much quicker. This allows the system to calculate how much fuel and air to give the engine with the most up-to-date information possible. Once the values are determined, they are sent to the actuators (fuel injectors, throttle, etc.). In older cars with distributors, the system uses the coils on the spark plugs to determine wits timing. In more complex systems, the spark plugs are fired by the controller when it determines the best time is ( based on information from the camshaft/crankshaft position sensors).

These aftermarket controllers can be used on just about any vehicle. There are many examples of cars, motorcycles, ATVs, and boats that are controlled by these DIY ECMs (for a list of successful vehicle projects using the MegaSquirt see DIY Auto Tunes site). Using one of these controllers gives you a great deal of flexibility in the car's engine set up. If you're building a track car, you can configure the car to run on the current engine, and then reprogram it later if you decide to change what engine to run. These controllers allow old cars to be brought into the same performance categories as newer ones. There are examples of very old cars obtaining land speed records using these systems [3].

- Manufacturers

- DIY EFI, MegaSquirt, MegaTunix, VEMS

- For More Information

- [1] How MegaSquirt EFI Controllers Work, MegaSquirt.

- [2] Versatile Engine Management Systems v3.3 Installation Instructions, VEMS.

- [3] Gary Hart's Land-Speed Record Holding Studebaker, DIY Auto Tune.

- [4] 280ZX Turbo Mega Squirt III Initial Startup, YouTube, Nov. 3, 2011.

- [5] Turabo Formula SAE 2011 Dyno Pull, YouTube, Nov. 27, 2011.

-

|