Air Flow Sensors

by Deborah Hood, Clemson Electrical Engineering Student

- Basic Description

-

Air flow sensors measure either the volume or the mass of air flowing in a channel. In an automobile, the primary use of an air flow sensor is to determine the amount of air drawn into the engine through the intake manifold. There are several types of air flow sensors: volume air flow sensors, which measure the effect of moving air on a pinwheel or deflecting plate, mass air flow sensors, which measure the mass of air as it passes through the sensor, Karman Vortex sensors, which determine the air velocity by measuring turbulence, and MEMS devices, which work much like mass air flow devices. As the load on an internal combustion engine varies, it is necessary to determine how much air is entering the cylinders in order to determine how much fuel to inject and how to adjust the engine timing. Because the stoichiometry of the air-fuel reaction depends fundamentally on the mass (proportional to the number of molecules) of the air, rather than the volume, the use of mass air flow sensors (MAFs) is much more widespread, although MEMS devices may eventually replace traditional MAFs due to their smaller profile.

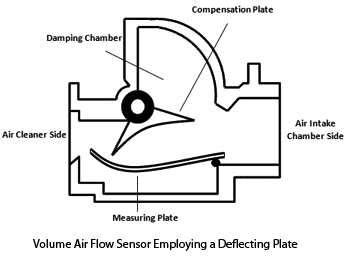

Vane Airflow Meters

The first airflow sensors to appear in cars measured the deflection of a plate placed in the airflow path. A compensation plate on a hinge swings back when more air is passing through and deflects off of a measuring plate. This plate is attached to a potentiometer which sends back a voltage to the ECU. Mechanically, this is not a very efficient method because it restricts the amount of air that can enter the intake chamber, and the potentiometer on the measuring plate will lose accuracy over time. This method does not take into account the temperature of the air, so an accurate air mass would be impossible to find.

Karman Vortex

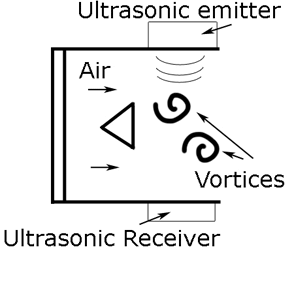

This sensor determines the velocity of the air flow by monitoring the frequency of an artificially induced turbulence using optical or ultrasonic sensors. The ECM combines this frequency with air temperature measurements to calculate the mass air flow. An optical sensor reflects light from an LED or an ultrasonic emitter off of a reflective surface (which oscillates in proportion to the vortexes in the air) onto a photodiode or to a receiver directly, and this signal is sent back to the ECU to calculate the volume of air. Either a barometer or intake air temperature sensor can be used to allow the ECU to determine the mass of the air.[7] Unlike heated element MAFs, Karman Vortex meters (except those which use LEDs) are more reliable because the ultrasonic wave penetrates through dirt and contaminants.[8]

Mass Airflow Meters (hot and cold wire)

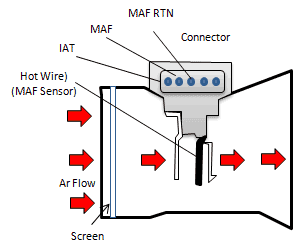

The most common designs use a thin resistive wire (usually platinum) that hangs down into the air flow. This wire is heated to a specified temperature, usually 100's of degrees Fahrenheit above the ambient temperature detected by the intake air temperature (IAT) sensor. As the air moving through the sensor cools the hot wire, the current flow through the wire changes. This current is detected by the sensor, which then relays this information to the ECM. Because this wire can collect contaminants, modern hot wire MAFs include a burn-off feature which heats the element up beyond normal operating temperatures to burn off any contaminants that collected on the sensor. New BMWs will feature this setup as opposed to MAP (Manifold Absolute Pressure) setups that were previously featured when efficient dynamics engines began production. Hot film sensors operate in a very similar way, but the sensor sends a frequency to the ECU instead of a current reading. Other types of mass airflow sensors include "cold-wire" sensors (which detect the varying inductance of a circuit connected to think metallic strips that vibrate as the air goes by) and membrane sensors (devices that use the change in temperature of a heated membrane to detect air flow in a manner similar to the "hot wire" sensor).

Membrane Sensor

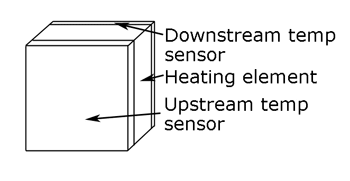

Membrane sensors are similar to hot wire MAFs in that they employ a heating element. The sensor detects the difference in temperature on each side of the element, and sends this information back to the ECU. A big advantage in using this sensor instead of a wire or film MAF is that membrane sensors can be manufactured to a smaller size, meaning that there is less blockage of air and increased performance.

Membrane airflow sensor

Karman Vortex sensor

Mass Air Flow Sensor

- Manufacturers

- Bosch, Continental, Delesen, Delphi, Denso, Gill, Hitachi, Honeywell

- For More Information

- [1] Mass Flow Sensor, Wikipedia.

- [2] Mass Air Flow Sensor (MAF), Automotive Illustrated Glossary at Samarins.com.

- [3] Mass Air Flow (MAF) Sensor, freeautomechanic.com.

- [4] Mass Air Flow Sensor (PID) , YouTube, Jan. 2008.

- [5] Vane Air Flow Sensor, YouTube, Aug. 9, 2010.

- [6] Making Sense of Engine Air Flow, Wells Manufacturing Corp., July 1999.

- [7] Making Sense Out of Sensors, Jim Halderman, Sinclair Community College. (ppt)

- [8] Advanced Automotive Electronics, MAF Karman Vortex, YouTube, Nov. 23, 2011.

|