Brushed DC Motors

- Basic Description

-

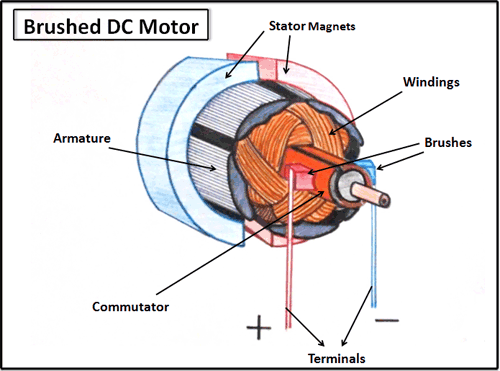

DC motors are in many ways the simplest electric motors. All DC "brushed" motors operate in the same way. There is a stator (a larger stationary part) and a rotor (a smaller part spinning on an axis within the stator). There are magnets on the stator and a coil on the rotor which is magnetically charged by supplying current to it. Brushes are responsible for transferring current from the stationary DC voltage source to the spinning rotor. Depending on the position of the rotor its magnetic charge will change and produce motion in the motor. The animation below further explains the basic operation of a DC motor. Utilizing a DC power source, very few controls are needed. To control speed an in-line variable resistance can be utilized to change the amount of current reaching the coils.

An animation of a DC electric motor in operation

The animation to the right shows a DC motor in operation. The motor shown is a simplified "two-pole" motor which uses just two magnets in the stator. In this case the magnets in the stator are permanent magnets for the sake of simplicity. A DC motor can get very complex when more poles are added but a standard "brushed" DC motor of any configuration operates on the same principles illustrated here. The brushes deliver current from a DC voltage source which supplies a magnetic field to that end of the rotor. The polarity of the field depends on the flow of the current. As the rotor turns the brushes make contact with one side of the DC source, then briefly do not make contact with anything, then continue making contact with the other side of the DC source effectively changing the polarity of the rotor. The timing of this change is determined by the geometrical setup of the brushes and leads to the DC source. The animation helps to illustrate how at the moment of maximum attraction the current will change direction and thus change the polarity of the rotor. At this moment the maximum attraction suddenly shifts to maximum repulsion which puts a torque on the rotor's shaft and causes the motor to spin.

- Components of a DC Motor

-

STATOR: The stator consists of either a permanent magnet or electromagnetic windings. The stator generates a stationary magnetic field around the rotor which occupies the central part of the motor.

ARMATURE (Rotor): The armature is made up of one or more electric windings around armature arms. These electric windings generate a magnetic field when energized by the external current. The magnetic poles thus generated by this rotor field are attracted to the opposite poles generated by the stator field and repelled by the similar poles, which causes the armature to rotate.

COMMUTATOR: The DC motor doesn’t use an external current switching device, instead it uses a mechanical connector called the commutator which is a segmented sleeve usually made of copper, mounted on the rotating shaft. The current +/- is supplied to this commutator segments with the help of brushes.

BRUSHES: As the motor turns the brushes slide over the commutator segments hence creating the variable magnetic field in different arms through the commutator segments attached to the windings. Hence a dynamic magnetic field is generated in the motor when a voltage is applied across the brushes.

The brushed DC motor has a mechanical sliding contact between the brushes and the commutator collar. The brushes and the spring carrying the current need replacing from time to time. The commutator also needs periodic cleaning or replacement.

- Manufacturers

-

Baldor,

Bosch,

Circor,

Emerson,

Groschopp,

Kinetek,

Lynch Motor Company,

Met Motors,

MicroMo,

Motion Control Group,

New Bharat Electricals,

Pittman,

Portescap,

Powertec,

Teco

- For More Information

- [1] Brushed DC Electric Motor, Wikipedia.

- [2] What is a DC Motor?, Wise Geek.

- [3] DC Electric Motors, tutorial on Georgia State University HyperPhysics web site.

- [4] Understanding and Using DC Motor Specifications, Gears Educational Systems, LLC.

- [5] How Does a DC Motor Work?, eHow.com.

- [6] Brushed DC Motor Basics Part 1 of 2, YouTube, Dec. 22, 2008.

- [7] Brushed DC Motor Basics Part 2 of 2, YouTube, Dec. 22, 2008.

- [8] DC Motor Calculations, National Instruments White Paper, Sep. 22, 2014.

|