The so called flexible fuel vehicle (FFV) runs on normal gasoline but also blends of gasoline and ethanol. In the US and Europe E85 is a common fuel which includes 85 % of ethanol and 15 % of gasoline. The limit in ethanol content is set to avoid cold starting problems during cold weather and to reduce ethanol emissions at low temperatures. Due to the lower energy density of ethanol compared to gasoline, the fuel economy is reduced by up to 30 %. However, the performance of the engine remains the same.

There are flexible fuel vehicles that adjust the fuel injection based on the oxygen sensor’s signal. The stoichiometric air/fuel mixture for gasoline is 14.7 whereas for E85 the required mass of air is 8.765 times the mass of the fuel to be burned in the cylinder. If the ethanol content in the fuel increases the oxygen sensor will indicate a lean mixture and the ECM will increase the amount of fuel injected. When using this method any change in the air/fuel ratio will result in an adjustment of the fuel injection, even though the change might be related to some failure in the system. Therefore, it is more accurate and reliable to employ a flexible-fuel sensor, also called flex-fuel sensor. The sensor determines the ethanol content of the fluent fuel before it is injected. For an immediate response the location of the sensor is chosen as close to the injector as possible.

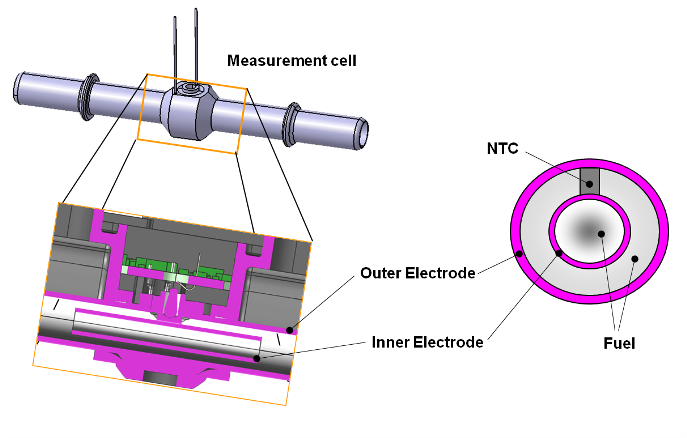

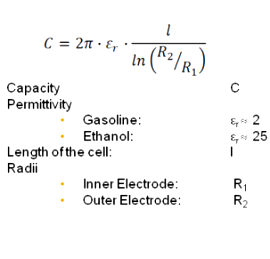

The picture above shows the measurement cell of the sensor. It is basically a cylindrical capacitor consisting of two tubes, the inner and outer electrode. The fuel flows through the gaps between. An AC voltage is applied to the electrodes. The relative permittivity of the fuel changes with the ethanol content, which leads to a change in the capacity accordingly (picture on the left). As the capacitance increases with increasing ethanol content, the oscillation frequency in the system will decrease and vice versa.

The analog frequency output is tied to a microprocessor which determines the capacitance by working backwards from the measured frequency. Due to the correlation between ethanol’s permittivity and the fluid’s temperature, the microprocessor corrects the capacitance for temperature variations in the fuel according to the output from an NTC (Negative Temperature Coefficient) thermistor. In addition, errors caused by the different conductivities of gasoline and ethanol are corrected.

The frequency of the single-wire output of the microprocessor to the ECM indicates the percentage of ethanol in the fuel. If required by the OEM the pulse width of the signal will indicate the fuel temperature. The ECM adjusts the injection according to the blend of the fuel, which leads to a stoichiometric combustion.