Oxygen Sensors

- Basic Description

-

An oxygen sensor is an electronic device used to measure the oxygen content

in exhaust gases. In the automotive industry it is also known as a lambda sensor,

and is used to regulate the air/fuel mixture and exhaust gas emissions in the

internal combustion engine. The lambda sensor is used to indicate whether the

fuel mixture is rich or lean. The

levels of oxygen are determined by exposing one electrode to the outside air and

another to the exhaust gas. The difference in oxygen content causes a flow

of electrons through a ceramic element that generates a voltage potential between

two boundary layers. The voltage created is directly related to the level of

oxygen content in the exhaust gas. An oxygen sensor is an electronic device used to measure the oxygen content

in exhaust gases. In the automotive industry it is also known as a lambda sensor,

and is used to regulate the air/fuel mixture and exhaust gas emissions in the

internal combustion engine. The lambda sensor is used to indicate whether the

fuel mixture is rich or lean. The

levels of oxygen are determined by exposing one electrode to the outside air and

another to the exhaust gas. The difference in oxygen content causes a flow

of electrons through a ceramic element that generates a voltage potential between

two boundary layers. The voltage created is directly related to the level of

oxygen content in the exhaust gas.

The lambda sensor is very sensitive to

temperature. The temperature of the ceramic element will determine its ability

to conduct the oxygen ions and essentially influence the response time of the

sensor. Most sensors are manufactured with an integrated electrical

heating element to sustain the response time at low

exhaust temperatures. This function assures that the emissions of the vehicle

are controlled over a wider range of engine operating temperatures, especially

during cold starts.

There are two different types of oxygen sensors that differ in the output signal. The Narrowband Sensor operates in a narrow air-fuel ratio (AFR) region and produces a significant "jump" in the signal voltage around when the AFR goes higher than Lambda while the Wideband sensor provides a signal over a wider range for lambda.

The Narrowband Sensor (aka Step Change Sensor)

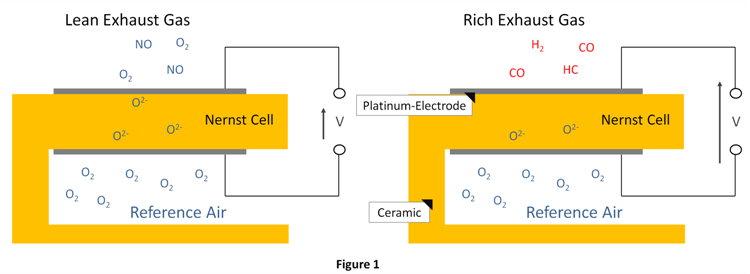

Narrowband sensors are often just called oxygen sensors because for many years this was the only type of oxygen sensor available. It is called a narrow band sensor because it can only detect a very narrow range of AFRs. The function of this sensor is based on an electrochemical cell called a Nernst cell (Figure 1). It is made up of Zirconia, an oxide of Zirconium, and an important property of Zirconia is that it can conduct oxygen ions above a temperature of about 350°C. When the sensor is fitted, the outside of the Zirconia element is exposed to the exhaust gas and the inside is in contact with reference air. Both sides of the element are coated with thin layers of platinum that act as electrodes and carry the sensor voltage from the Zirconia element to the lead wires. At operating temperature, oxygen ions are able to pass through the element and deposit charge on the platinum electrodes thus generating a voltage.

The Narrowband Sensor is basically an on/off switch in that it can determine if the mixture is lean or rich, but it doesn't tell the ECU how lean or how rich the mix is. It communicates with the ECU via the voltage it produces. If the AFR is rich, a HIGH signal voltage is generated across the electrodes due to the difference in oxygen concentration present across the two sides of the element. Conversely, if the AFR is lean, a LOW voltage is generated across the electrodes due to the small difference in oxygen content between exhaust gases and the reference air inside the sensor.

-

The Wideband Sensor

Wideband sensors, also known as wide-range sensors, are a newer technology. The wideband sensor not only tells the ECU if the mix is rich or lean, but how rich or how lean it is. In this way, it's easier for the ECU to adjust the mix without a lot of overshoot and guess work. For this reason, the wideband sensor is a superior technology, and it is likely that wideband sensors will ultimately replace narrowband sensors in all cars and trucks.

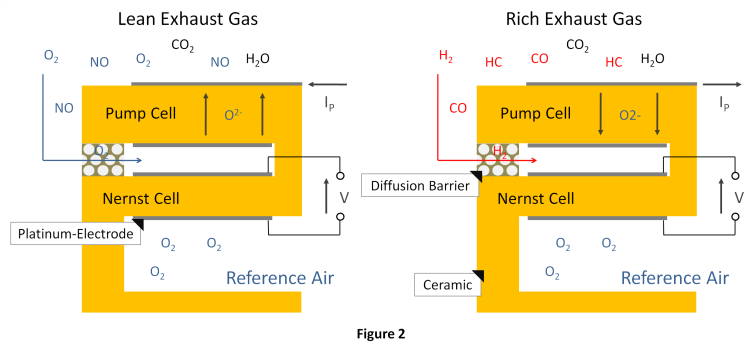

Wideband sensors have an additional ceramic cell (Figure 2).The exhaust gas partially diffuses through the diffusion barrier. The AFR of the exhaust gas in the chamber is measured with the Nernst cell. Depending on whether the AFR in the chamber is rich or lean, a control circuit applies a voltage to the electrodes of the pump cell. Oxygen ions are transported from the inner to the outer electrode so that the AFR in the chamber becomes lambda = 1. The generated electric current, Ip, is the signal. There is a specific range of current corresponding to lambda from 0.7 to infinity. The signal is zero when the AFR of the exhaust gas is lambda = 1. The output curve permits steady control with a predetermined nominal value for lambda.

-

Properties of Modern Oxygen Sensors

The heating elements of oxygen sensors are typically controlled in an open loop with a pulse width modulated voltage, though modern sensors often have heating elements that are controlled in a closed loop. The measured resistance of the ceramic indicates the temperature, so the energy needed to hold the temperature constant can be readily calculated. Closed loop control assures a more reliable signal in different environmental conditions.

In addition, many modern oxygen sensors do not need outside air as a reference. Rather, a reference pump current is applied to the Nernst cell, which simulates the influence of the air. In these sensors, a gap in the element for the reference air is not required. Therefore, the sensor element requires less volume and heating it up requires less time and energy. Furthermore, operating without reference air makes the sensor less sensitive to contamination.

- Manufacturers

- ACDelco, Beru, Bosch, Delphi, Denso, McLaren Electronics, Motorcraft, NGK, Standard

- For More Information

- [1] How does the Oxygen Sensor in a Car Work?, HowStuffWorks.com, Apr. 1, 2000.

- [2] Oxygen Sensor, Wikipedia.

- [3] Oxygen Sensors Are a Critical Key to Passing Emissions, Autohaus website.

- [4] All About Lambda Sensors, Pico Technology website.

- [5] O2 Sensor Basics, YouTube, July 24, 2009.

- [6] How Does the Lambda Sensor Work, NGK website, updated Jan. 14, 2013.

- [7] Oxygen Sensor Demonstration, YouTube, Apr. 20, 2015.

|