Position Sensors

- Basic Description

-

Position sensors are used in automobiles to determine the steering wheel position, pedal positions, seat positions, and the position of various valves, knobs and actuators. There are three main types of position sensors: angular, rotary, and linear. These sensors utilize various technologies to sense position including wiper-arm potentiometers, optical reflection or imaging, and Hall-effect sensors.

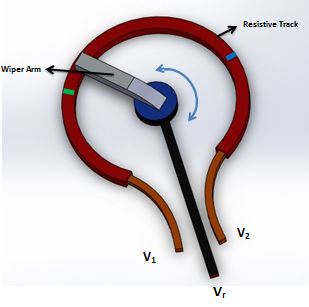

Wiper-arm potentiometers are often used to measure angular position. As a rotating shaft turns, the wiper arm sweeps across a resistance track. The resistance between one end of the track and the wiper arm indicates the amount of rotation. Even though the wiper-arm potentiometer is cheap and relatively easy to manufacture, there are a number of disadvantages including wear, foreign particle contamination, and wiper-arm lift-off caused by vibration.

Optical position sensors utilize a phototransistor or optical image sensor to track the movement of optical marks or changes in an image. For example, optical crankshaft position sensors detect light reflected from the rotating surface of the shaft with alternating light and dark marks. Optical position sensors are frictionless and do not require physical contact with the object being measured. On the other hand, they can be susceptible to dirt and other impurities on the surface of the object or in the air space between the object and the detector.

Hall-effect sensors detect the effect that an applied magnetic field has on the resistance of current flowing through a wide conductor. These sensors generally sense the position of the sensor relative to a permanent magnet. They have the advantage that they are non-contact and relatively immune to dirt and vibration (although they are susceptible to strong magnetic fields). Hall-effect sensors are active devices that require an operating voltage to be applied to them. These sensors are often used for sensing the position of the accelerator pedal in automobiles.

Inductive position sensors measure the proximity of a magnetic material such as steel or the proximity of a small loop of wire. These sensors consist of a small coil of wire driven by a time-varying current. The inductance of the coil changes when the coil is in close proximity to a magnetic material or a passive loop of wire. Like Hall-effect sensors, these are active devices, because a current must be applied to the coil in order to measure its inductance.

An advanced form of inductive sensor employed by Hella in their accelerator pedal position sensors uses a digital component to drive a coil with a high-frequency current. The magnetic field from this coil couples to a passive coil on the rotating part that creates another field that couples back to a series of coils on the stationary part. The relative phase of the currents coupled to these coils is used to determine the position of the rotating coil.

- Manufacturers

- Allegro Microsystems, Balluff, BEI Sensors, Bosch, Bourns, Continental, CTS, Delphi, Denso, Gill, Hella, Infineon,

iTarget, Honeywell, Methode Electronics, McLaren Electronics, Murata, Nippon Seiki, Novotechnik, NXP,

Piher, Positek, TE Connectivity, Variohm, Vishay, Wells Vehicle Electronics

- For More Information

- [1] Potentiometer, Wikipedia.

- [2] Inductive Sensor, Wikipedia.

- [3] Basic Hall Effect Sensors, YouTube, Dec. 25, 2010.

- [4] Using Various Hall Effect Sensors Tutorial, Schematics and Code, YouTube, Apr 16, 2011.

- [5] Magnetostrictive Linear Position Sensors,SensorLand.com.

- [6] Active Accelerator Pedal Sensor, Hella.com.

- [7] New Dual Brake Pedal Position Sensor, Techlink, Aug. 2, 2012.

- [8] Position Sensing in Vehicles: How New Magnetic Encoder Technology Helps Ensure Accurate, Fault-free Sensor Outputs, Marcel Urban, EE Times - Europe, July 29, 2010.

- [9] Basic Functionality of Inductive Proximity Sensors by Balluff, YouTube, Jan 5, 2011.

|