Crankshaft and Camshaft Position Sensors, Engine Speed Sensors

- Basic Description

-

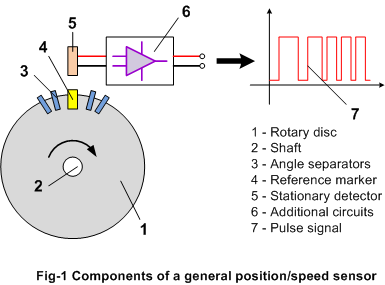

Crank or camshaft position sensors and engine speed sensors are similar devices that operate based on pulse detection and counting. The fundamental components of these sensors include a toothed disc mounted on the shaft, a stationary detector and electronic circuitry (Fig-1). The disc has teeth or marks distributed evenly around the circumference. When the shaft spins, teeth or marks pass by the stationary detector and generate a series of electrical pulses. The frequency of these pulses is detected and converted to the corresponding shaft rotation speed. The relative angular position can be obtained by counting the number of pulses. Additional reference markers are required to sense the absolute position of the crank or camshaft. The Crank position sensor is usually mounted in the crankcase over the toothed wheel on the crankshaft. The Camshaft position sensor is usually mounted in line with the toothed wheel on the end of the camshaft. It is usually hidden under the timing chain cover on the front of the engine. Some sensors have two sets of discs with a constant phase shift in order to determine the direction of the rotary motion.

Generally, there are four types of crankshaft or camshaft position sensors: magnetic pick-up coils, Hall-effect sensors, magneto-resistive element (MRE) sensors, and optical sensors. The first three utilize the metal teeth of a wheel to generate a series of electric pulses, based on changes in the magnetic field, as the teeth come into the proximity of the sensor. Optical position sensors use a light-emitting diode (LED) light source and a photodiode to detect optical marks on the shaft or slots in a disk as they move past the detector. Optical sensors have a good degree of accuracy and are suitable for both high-speed and low-speed applications, but the optical components and disc must be kept clean to ensure an accurate reading.

- Manufacturers

- Bosch, BWD, Continental, Delphi, Denso, Duralast, Methode Electronics, NAPA Echlin, Standard, Tamagawa Seiki

- For More Information

- [1] Crankshaft Position Sensor, Wikipedia.

- [2]

Rotary Encoder, Wikipedia.

- [3]

Crankshaft Position Sensor,

YouTube, Sep. 28, 2007.

- [4]

How to Test Crankshaft and Camshaft Sensors 1,YouTube, Dec. 9, 2007.

- [5] Automotive Crank Sensor Operation ,YouTube, Jan. 26, 2008.

- [6] How to Test an Inductive / AC Generator Crankshaft Position Sensor (CKP),YouTube, Sep. 23, 2011.

|