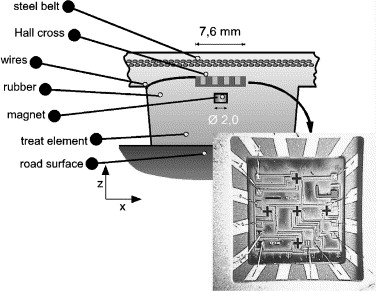

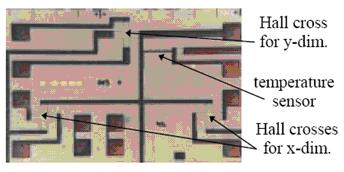

DARMSTADT TIRE SENSORThe Darmstadt tire sensor system was developed at Darmstadt University, Germany. The system includes a permanent magnet mounted within the tire rubber. The position and deformation of the magnet are monitored by a position sensor, which employs four monolithically integrated Hall crosses and an additional temperature sensor. The distance between the magnet and the position sensor is 1 mm [1]. The sensor concept is shown in Figure 1. The small size of the sensor makes it possible to place the chip and magnet in a single tread element, thus reducing the influence of the steer belt on the magnetic field. Furthermore, this configuration reduces the power consumption so as to increase the life of the sensor. The sensor resolution mainly depends on the Hall cross magnetic field sensitivity, the size of the magnet and the distance between the magnet and the Hall crosses. Figure 2 provides a section view of the sensor showing three hall crosses. The differential signals from the two crosses in the x- and y directions deliver the x- and y-deformation output signal. The sum of the four Hall voltages forms the z signal. The relationship between the deformation and friction force is based on the brush model. Although test of the sensor to date have been performed on a test bench, the sensor has the potential to estimate the actual friction forces between tire and road.

Figure 1: Illustration of Darmstadt Tire Sensor [1]

Figure 2: Section View of the Position Sensor [1] Reference[1] M. Brandt, A. Vogt, H. Dang, V. Bachmann, "Monolithically Integrated AlGaAs/GaAs 3D Magnetic Field Sensors," Nov. 01, 2006. |