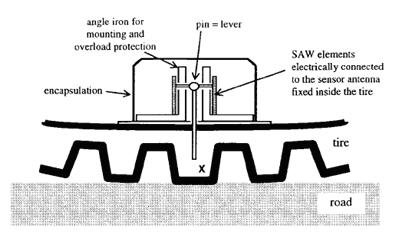

SURFACE ACOUSTIC WAVE (SAW) SENSORSurface acoustic wave sensors are so named because their detection mechanism is a mechanical, or acoustic, wave. A piezoelectric material is used to generate the acoustic wave. Piezoelectricity refers to the production of electrical charges by the imposition of mechanical stress. The electrical charges can also cause mechanical stress. SAW sensors apply an oscillating electric field to create a mechanical wave. As the wave propagates through the substrate, the velocity and amplitude of the wave can be monitored by measuring the frequency or phase characteristics of the electrical signal from the sensor. The RF operation frequency is limited by the substrate size and by the photolithographic process. SAW devices are generally manufactured to operate in the frequency range between 30 MHz and 3 GHz. Acoustic wave sensors are intrinsically reliable and can be integrated passively and wirelessly. Wireless sensors are well suited for monitoring moving objects, such as tires. The Vehicular Technology Department at the University of Darmstadt, Germany has developed SAW tire sensors to measure tire pressure and friction. One configuration is illustrated in Figure 1 [1]. Two advantages of this implementation are that no operating power is required for the part of the sensor inside the tire and sensor mass is very small. Transense, Smartire, and Michelin cooperated to design SAW sensors whose power is supplied by the receiver components. Siemens has announced that they are cooperating with Continental and Darmstadt University to develop a SAW sensor integrated into the actual tire tread.

Figure 1: Configuration of SAW Sensor [1] Reference[1] Alfred Pohl, Reinhard Steindl, and Leonhard Reindl, "The 'Intelligent Tire' Utilizing Passive SAW Sensors - Measurement of Tire Friction," IEEE Trans. Instrum. Meas., vol. 48, pp. 1041-1046, Dec. 1999. |