Modeling the Capacitance of an SMT Capacitor with Q3D

Geometry and setup |

Pad size: 0.5 mm × 0.5 mm × 0.017 mm

Cathode/Anode: 0.5 mm × 0.1 mm × 0.5 mm

Plate: 0.5 mm × 0.7 mm × 0.05 mm

Dielectric: 1.5 mm × 1.8 mm × 0.1 mm

Gap between any two plates: 0.1 mm

Capacitor size: 1005

Dielectric: εr = 4.4

Solve Setup:

Solver residual: 0.0001

Adaptive solution:

- Maximum number of passes: 10

- Minimum number of passes: 1

- Minimum converged passes: 1

- Percent error: 1%

- Percent refinement per pass: 30%

q3d_smtcap.zip

q3d_smtcap.zip |

Simulation result |

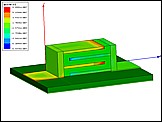

Anode Capacitance: 0.521 pF

Cathode Capacitance: 0.524 pF

Mutual Capacitance: 0.495 pF

|

Decisions the user must make that affect the accuracy of the result |

- Solver residual : 1e-005

- Percent error for adaptive solution: 1%

- Dielectric constant of the capacitor

- Distance between two electrodes

|

Comments |

- The distance between plates is much larger than we would find in an actual SMT Multi-Layer Capacitor (MLC).

Why not model a more realistic geometry?

The complexity of a real SMT MLC would require significantly greater computer resources

to model accurately and the solution would be sensitive to details in the problem geometry and in

the mesh geometry. While a great deal can be learned about the factors affecting the capacitance

of an SMT MLC from these models, it is not likely that two different codes would yield identical

results.

|

|

Screen shots

Fig. 1. Simulation model

Fig. 2. Simulation meshes

Fig. 3. Charge density

|

|