Clemson in the Low Country

Clemson University expands course offerings at Zucker Family Graduate Education Center in North Charleston

by Paul Alongi

Stronger Together

Collaboration is paying off for Clemson University and MUSC.

by Paul Alongi

Preserving the Past

The Warren Lasch Conservation Center offers a behind-the-scenes look into current conservation efforts in the lowcountry.

by Stéphanie Cretté

On the Pulse

CU-ICAR research teams keep industry moving toward sustainability.

by Leah VanSyckel

Broadening Graduate Horizons

A strategy aimed at expanding graduate and research programs in the college has made progress, led by outgoing board chairman Ron Lindsay.

by Paul Alongi

FROM THE DEAN

Charleston is one of the fastest growing metropolitan areas in the country, with an expected overall population increase of 9.3 percent between 2015 and 2020. This region has seen a parallel increase in industry, most notably in the fields of information technology and advanced manufacturing. Examples include the Boeing assembly plant that opened in 2011, and Volvo’s announcement that it would invest $1 billion and employ 4,000 at a new automobile plant by 2030. This growth is possible, in part, because Charleston is the site of one of the largest ports on the East Coast.

These new industries have brought a steady increase in jobs and strong economic indicators. According to the U.S. Bureau of Labor Statistics, the Charleston area added 50,500 new jobs between 2005 and 2014, with employment in the region growing 17.4 percent. This means Charleston is outpacing cities such as Seattle, Nashville, Salt Lake City and the national average of 4 percent. Average annual pay grew 23.7 percent from 2005 to 2013.

The economic upswing appears to be continuing. Charleston recently made State Tech’s list of the top 12 tech hubs in America that are “nipping on Silicon Valley’s heels.” The current industrial climate indicates that Charleston’s impressive growth has created a need for research-oriented graduate programs in engineering and computer science.

Clemson, as a land-grant institution, and the College of Engineering and Science in particular, are perfectly positioned not only to fulfill this educational need but also to foster new growth through research and innovation. For example, one of our new initiatives is the energy research being conducted at the Clemson University Restoration Institute. One project, which is supported by a grant of $6.7 million from the U.S. Department of Energy, involves a collaboration of Clemson experts and the DOE on research that could reduce energy consumption worldwide by developing more efficient industrial motors.

In the future, the focal point of our educational efforts in the Charleston area will be centered on the Zucker Family Graduate Education Center, which is currently under construction at the Clemson University Restoration Institute. When the Center opens this fall, students will find state-of-the-art classrooms, conference rooms and space to collaborate with industry. It will seamlessly connect to the main campus in Clemson using the interactive technology incorporated in the new Watt Family Innovation Center. Initially, the Zucker Center will offer research-oriented graduate

programs in digital production arts, computer science, electrical engineering and mechanical engineering.

Another key piece of the college’s Lowcountry presence can be found in downtown Charleston, where the Clemson-MUSC Bioengineering Program is headquartered in a new building at the Medical University of South Carolina. Clemson bioengineers are collaborating with MUSC scientists and clinicians on a range of research projects representing the key, emerging sub-disciplines of biotransport and drug delivery, matrix and tissue engineering, and dental and maxilla-facial reconstruction, among others. This collaboration attracts grants, strengthens the educational experience for students and builds on each institution’s strengths to encourage innovation.

Always key to our pursuit to achieve excellence are the alumni and industry leaders who help guide us. In this issue of IDEaS, Ronald C. Lindsay reflects on his tenure as chairman of the College’s Advisory Board. Our current chairman, Michael Watt, tells us about his family’s deep roots at Clemson and his vision for the Watt Family Innovation Center. As we move forward in the Lowcountry, we appreciate their wise counsel.

The college’s presence in the Lowcountry is where some of the best minds from academia, industry, government and community will converge and truly define its philosophy of innovation through translation in the broader areas of energy, big data, cyber physical security and health care. We hope that in doing so we will create a better future. It is through our partnerships that we continue our quest for pre-eminence in research and education, and we invite you on this journey to define the future.

Anand Gramopadhye, Dean

College of Engineering and Science

CLEMSON IN THE

LOWCOUNTRY

Clemson University expands course offerings

at Zucker Family Graduate Education Center

in North Charleston.

By Paul Alongi

Clemson University’s announcement that it will further expand its course offerings in Charleston was met with cheers from officials who said the programs would provide new opportunities for working professionals to advance their careers and could launch a video game industry based in the Lowcountry.

Master’s degree programs in electrical engineering and systems engineering will complement the previously announced degree programs that Clemson expects to provide at the $21.5-million Zucker Family Graduate Education Center starting in the fall. University officials also said they will expand Digital Production Arts to include more instruction in video game design and content development in hopes of creating a Charleston-based industry. Most of the program’s students, who are now on the main campus in Clemson, will be based out of Charleston in three years, officials said.

The Zucker Center is under construction at the Clemson University Restoration Institute and will include state-of-the-art classrooms, conference rooms and space for industry. Classrooms with cutting-edge technology will connect the Zucker Center to Clemson’s main campus. High-resolution cameras will have motion sensors, so if a student raises a hand, the camera will pan to the action. The announcement rounds out what Clemson has planned for the former naval complex in North Charleston. The University previously announced that its Charleston-area offerings would include a master’s degree program in mechanical engineering and a Ph.D. program in computer science.

The Zucker Center is under construction at the Clemson University Restoration Institute and will include state-of-the-art classrooms, conference rooms and space for industry. Classrooms with cutting-edge technology will connect the Zucker Center to Clemson’s main campus. High-resolution cameras will have motion sensors, so if a student raises a hand, the camera will pan to the action. The announcement rounds out what Clemson has planned for the former naval complex in North Charleston. The University previously announced that its Charleston-area offerings would include a master’s degree program in mechanical engineering and a Ph.D. program in computer science.

Robert Jones, executive vice president for academic affairs and provost, said the advanced degree programs would be the only ones of their kind in the Lowcountry.

“Most of the programs target working professionals who need advanced degrees to further their careers in a variety of industries, including aerospace, automotive, defense and energy,” he said. “The quick rise of advanced manufacturing in the Lowcountry has created a growing need for these programs. We’re pleased to help fill the need by providing students with a high-quality education in a new, state-of-the-art facility.”

Randy Collins, executive director of academic initiatives in the College of Engineering and Science, said that an area long known for its beaches, tourism and retirees now has fast-growing aerospace and automotive industries.

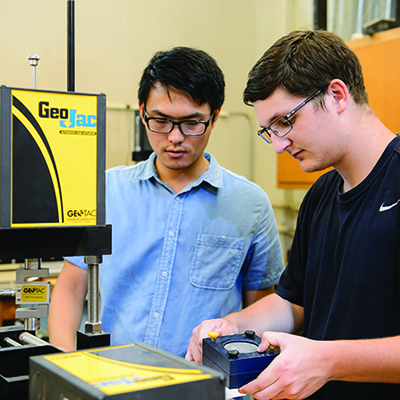

Impressive growth in the Charleston area has created a need for research-oriented graduate programs in engineering and computer science. Clemson University is perfectly positioned to fulfill the educational need and foster growth, as Yue “Sophie” Wang and a host of other faculty members help boost the University’s reputation for cutting-edge research.

Impressive growth in the Charleston area has created a need for research-oriented graduate programs in engineering and computer science. Clemson University is perfectly positioned to fulfill the educational need and foster growth, as Yue “Sophie” Wang and a host of other faculty members help boost the University’s reputation for cutting-edge research.

“Nobody is sitting still,” Collins said. “Businesses are opening. Industry is expanding. There’s a critical need for high-quality graduate education, particularly in the engineering and computing disciplines. We’ve heard over and over the value of personalized interaction with faculty and fellow students. That’s not something you can get online.”

Melur “Ram” Ramasubramanian, chair of the Department of Mechanical Engineering, said the opportunity to earn advanced degrees in Charleston would fuel economic growth, helping industry attract top-notch employees.

“It’s an exciting opportunity for Clemson to bring high-quality graduate education to the Charleston area and be a significant contributor to economic development,” he said. “We’re excited to be a selling point to come to Charleston.”

Clemson’s expansion is in the heart of the Charleston-North Charleston metro area, the 17th-fastest growing metro area in the country, according to the U.S. Census Bureau. The fourth fastest, Myrtle Beach-Conway-North Myrtle Beach, lies just to the north. The 13th fastest, Hilton Head Island-Bluffton-Beaufort, is immediately to the south.

Growing need for electrical engineers

Dan Noneaker, chairman of the Holcombe Department of Electrical and Computer Engineering, said several Charleston-area employers are in need of electrical engineers with advanced degrees. They include the Space and Naval Warfare Systems Center Atlantic, and the area’s defense contractors. Furthermore, electrical utilities have told him they face a wave of retirements over the next five years.

“They’re going to need manpower,” Noneaker said. “A lot of advanced technical work requires advanced preparation.”

Clemson’s Charleston facilities include the Duke Energy eGRID and a wind turbine drivetrain testing and research facility, led by Nikolaos Rigas.

Noneaker expects that Charleston-based electrical engineering students will earn their master’s degrees with a combination of classes taught in person at the Zucker Center and classes taught from Clemson and transmitted live to the Zucker Center.

All five graduate degrees offered in electrical and computer engineering will eventually be available to students through courses sited at the Clemson University Restoration Institute, although they will emerge at differing rates, Noneaker said. Students will also be able to take some courses from local partners, including graduate engineering courses through The Citadel.

The other program recently announced is a multidisciplinary Master of Systems Engineering with tracks in cyberphysical security, power and energy systems, and manufacturing composites. The program is coordinated out of the office of the dean of the College of Engineering and Science.

While most of the programs are at the master’s level, more opportunities for research and doctoral degrees will come as Clemson ramps up operations in the Lowcountry, officials said.

“We will have an opportunity to develop new research capabilities based on the unique facilities we have located there,” Noneaker said.

Those facilities include the Duke Energy eGRID and a wind turbine drivetrain testing and research facility. They form the cornerstone of the SCE&G Energy Innovation Center and are the largest facilities of their kind in the world.

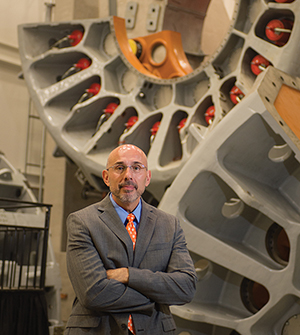

Nikolaos Rigas, executive director of the Clemson University Restoration Institute, said the facilities represent $110 million in public and private investment.

“Because of our cutting-edge facilities, we can offer research opportunities that are available here and only here,” Rigas said. “As the Zucker Center grows, so will our research portfolio.”

Collins, who developed the precursor to the eGRID and was an investigator on the eGRID project, added: “The work we do in Charleston is not only helping generate and distribute energy more reliably and sustainably, but is also giving students an unparalleled research experience. The sky’s the limit as we move forward.”

Building an industry

Clemson announced in May that Digital Production Arts will be among the first programs available at the Zucker Center and that program co-founder Robert Geist, who has a credit in “The Hobbit: An Unexpected Journey,” will be among the first professors based out of Charleston. University officials have provided more detail, saying they hope to capitalize on the “Silicon Harbor” tech sector to create a video game industry.

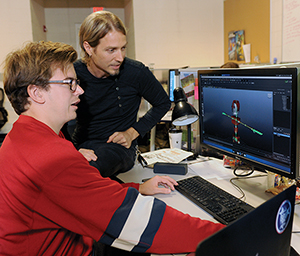

Victor Zordan, the new director of Digital Production Arts, said the IT startups already doing business in the Charleston area provide one of the key ingredients. Clemson will provide the other — experts who design games and develop content.

“If we can build talent in that area, then we can build industry,” Zordan said. “This is going to be good for South Carolina. This is going to build jobs and businesses in Charleston. We’re putting everything together in the right place to have growth.”

Students in the program work toward receiving a Master of Fine Arts. Digital Production Arts has been Clemson’s pipeline to Hollywood since 1999, preparing students for the animation, visual-effects and electronic-game industries. More than 150 alumni have garnered credits in films ranging from “How to Train Your Dragon” to “Kung Fu Panda 3.”

As Clemson beefs up its video-game offerings, students will continue to learn the skills they need to create animation and visual effects for TV and movies, Zordan said. He expects the number of master’s students in the program to more than triple from about 30 to 100. About two-thirds of them will be based out of Charleston in three years, Zordan said.

“It’s a tech environment, it’s an arts environment and it’s a city,” he said. “Going to Charleston will ignite our plans to build an industry.”

Mechanical engineering offerings to grow

Clemson has been offering a master’s program in mechanical engineering in the Charleston area since January 2015 at the Lowcountry Graduate Center. Those classes will move to the Zucker Center when it opens, Ramasubramanian said. Offerings are expected to expand from one class per semester to two starting in fall 2016. Classes are held at night and run three hours, targeting working professionals.

Courses are offered in a “hybrid mode,” Ramasubramanian said. Instructors teach from Clemson two out of every three weeks, while students in Charleston tune in remotely from a state-of-the-art distance-learning classroom. Every third week instructors go to Charleston to teach in person and hold office hours, and Clemson-based students tune in remotely.

“It’s an identical program to what students on the main campus get, including an opportunity to interact with faculty and get involved with research,” Ramasubramanian said.

Collins said employers value the advantage of a technical degree with a research focus.

“Through personal interaction with the faculty, Clemson’s graduate programs offer the opportunity to work on a research project that leads to a thesis — one that could focus on solving a real problem the student is encountering in the workplace,” he said.

New opportunities for computer science degrees

Clemson will also offer a Ph.D. program in computer science at the Zucker Center. Eileen Kraemer, the C. Tycho Howle Director of the School of Computing, said rapid growth in advanced manufacturing and the Charleston-area tech sector is driving up the demand for advanced computing degrees.

“We are excited to provide a high-quality Ph.D. program in an area where there is a fast-growing need,” she said. “Charleston-based students will receive the same degree as those on the campus in Clemson. It’s a win for the students, it’s a win for Clemson, it’s a win for industry, and it’s a win for the economic development of the state.” ✲

IDEAS Spring 2016

STRONGER TOGETHER

Collaboration is paying off for Clemson University and MUSC.

By Paul Alongi

The Bioengineering Building stands four stories tall, its red brick offset by metal-framed windows in the bustling heart of campus at the Medical University of South Carolina (MUSC). Inside the gleaming new structure, researchers work on cutting-edge bioengineering challenges, seeking new treatments for TMJ disorders, brain injuries and damaged tissue.

But what makes the building especially remarkable is that MUSC has no bioengineering department. The bioengineers who work on campus come from the state’s other research universities, making the building itself a temple of collaboration.

A key driver of this collaboration is the Clemson-MUSC Bioengineering Program. As part of the program, six Clemson bioengineers based on the MUSC campus in downtown Charleston collaborate with MUSC scientists and clinicians on a range of research projects.

It’s a combination that helps attract grants, strengthens the educational experience for students and builds on each institution’s strengths to supercharge innovation, researchers said.

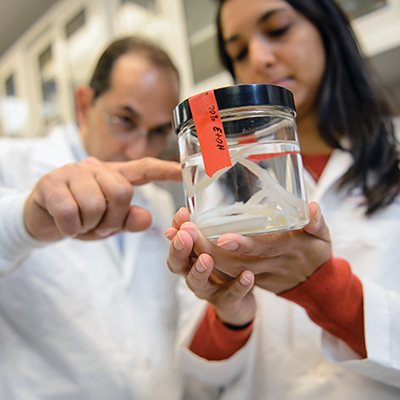

Hai Yao, the associate chair for Clemson’s Department of Bioengineering, said the program is going as strong as ever. Since it started in 2003, the program has generated $25 million in grants and graduated 41 Ph.D. students with 16 more in the pipeline.

“We’ve become a unit integrated on the MUSC campus,” Yao said. “This is a model system for other programs. This is the most successful program between a medical school and an engineering program in the nation.”

The Bioengineering Building opened in 2012 as part of the $120-million James E. Clyburn Research Center. The idea behind the center, which also includes the Drug Discovery Building, is to foster collaboration among Clemson, MUSC and the University of South Carolina.

Yao is deeply immersed in the collaboration. He is based out of the Bioengineering Building, oversees the Clemson-MUSC Bioengineering Program and collaborates on research with Michael J. Kern, a professor in the Department of Regenerative Medicine and Cell Biology at MUSC.

Yao and Kern are working together to find new ways of repairing or replacing defective jaw joints to ease the pain of patients who suffer from TMJ disorders.

“I’m not a biologist,” Yao said, while standing next to a microscope. “It’s hard for me to interpret these results. Instead of visiting once a month, I can call Dr. Kern and say, ‘Can you stop by and check these results after class?’ That’s key.”

Kern said the collaboration has been tremendously helpful for both sides.

“It’s a unique niche that fulfills what the NIH (National Institutes of Health) wants,” he said. “NIH wants the biologists and engineers to work together.”

A majority of the funding that flows through the program has come from the NIH, Yao said. Funding has also come from the National Science Foundation, the Department of Defense, private industry and foundations.

Martine LaBerge, chair of Clemson’s Department of Bioengineering, said the $25 million in funding and the Bioengineering Building speak volumes about the success of the program and its benefits to the state.

“We’re seeing a pattern of continuous investment in the program,” she said. “It’s a model for how research universities can break down silos and work together, building on each other’s strengths.”

Six Clemson faculty members form the core of the Clemson-MUSC bioengineering program, while 41 others from the two institutions play supporting roles. Clemson students who participate have the same privileges as MUSC students, ranging from access to the cutting-edge labs to use of the wellness center. Clemson students at MUSC can even serve on MUSC’s student government.

Larry Dooley was associate dean of the College of Engineering and Science in 2003 when he played a key role in launching the program.

“When we started the program, I said that Clemson and MUSC aren’t competing against each other,” Dooley said. “We’re competing against the world. That’s as true now as it was then. The program has done extremely well, and we’re expecting big things still to come.” ✲

PRESERVING THE PAST

The Warren Lasch Conservation Center offers a behind-the-scenes look into current conservation efforts in the Lowcountry.

By Stéphanie Cretté

The Warren Lasch Conservation Center (WLCC) at the Clemson University Restoration Institute in North Charleston, S.C., is a facility dedicated to implementing best practices and advancing knowledge in the analysis, documentation and conservation of historic materials. The WLCC champions an integrated research approach in which conservators, archaeologists, historic preservationists and material scientists work together to solve preservation challenges. The 45,917-square-foot facility houses state-of-the-art laboratories dedicated to material analyses, characterization and documentation. It was initially built in 1999 to house the H.L. Hunley, a submarine that sunk off the coast of Charleston in 1864 and was retrieved from the seafloor more than 136 years later. That exhibit, which is operated by Friends of the Hunley, still draws tourists from all around the world.

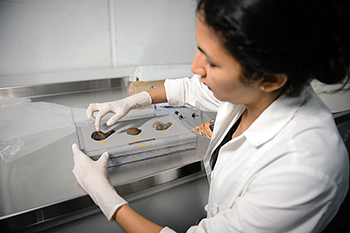

The center later evolved to study more than the Hunley. In 2002, Clemson scientists were asked to develop new methods to stabilize iron artifacts that had become corroded and encrusted with marine growth. While the team’s efforts continue to focus on conserving the submarine, the team has grown and branched out to other artifacts and documenting historic structures on land.

One of the techniques researchers have developed at the WLCC is a treatment using subcritical fluids to stabilize metal artifacts by desalination. Treatment times are a fraction of those required by the conventional soaking methods; chloride readings are brought to near-negligible levels; desalination can be carried out with or without prior deconcretion; solutions are maintained in sealed containers for the duration of the treatments; and positive results have been seen so far for long-term stability of treated artifacts.

During the process, an unstable artifact is selected, documented and presoaked in the treatment solution for a minimum period of 24 hours prior to treatment. The specimen is then introduced into a stainless steel reactor cell. The cell is filled with the treatment solution, air is purged from the system and the temperature is gradually raised to 356 degrees Fahrenheit.

The chamber pressure is increased and maintained at 50 bar. Heat and pressure remain below the critical point of 374 degrees Celsius, allowing the solution to remain in liquid phase while considerably improving the transport properties of the fluid.

The successes with subcritical fluids to stabilize iron have led to collaboration with Cardiff University in the United Kingdom, hosting Ph.D. research focused on investigating the applicability of subcritical fluids to stabilize copper alloy artifacts, a metal abundantly present in the archaeological record.

Researchers at the WLCC have also successfully applied a supercritical carbon dioxide to waterlogged organic materials. Industry has long used supercritical carbon dioxide methods for a variety of uses, including decaffeinating coffee, but Clemson researchers were among the first to apply the technique to conserving artifacts.

The treatment enables researchers to dry things such as waterlogged cork with minimal changes to the physical characteristics. Thanks to this method, they have been able to conserve cork artifacts from several shipwrecks.

Researchers have become the go-to team for conserving artifacts and structures of cultural heritage in the United States and globally. The Fort Sumter National Monument, a unit of the National Park Service, approached WLCC in 2008 to develop conservation treatments for cannon and architectural elements at Fort Sumter and Fort Moultrie. The WLCC team members are continuing their efforts to preserve one of the most unique and complete collections of ordnance, artillery items and coastal defense architectural elements under an ongoing collaborative agreement. A new treatment protocol has been developed using a superheated water system to gently remove failing coating layers and loose corrosion and to apply corrosion inhibitors to the historic metals. More recently, three Civil War-era cannons discovered in the Pee Dee River were delivered to the facility by SCIAA for conservation.

ABOVE: Since 2000, Clemson scientists have used advanced technology to preserve and document the Hunley for future generations.

Since its inception, the WLCC has advanced the practice of digital documentation in the archaeological science with its systematic digital recording of the H.L. Hunley. Today, researchers are again expanding the research portfolio of the lab through a program called the Lowcountry Digital Documentation Initiative (LDDI). Through the LDDI, Clemson researchers aim to both document and help manage the architectural fabric of the region. The end goal is to provide the public at large with cultural heritage data for the entire region.

Beyond the Lowcountry, the WLCC has begun working on digital documentation projects in UNESCO World Heritage Sites on Bermuda, Cuba and the north coast of Jamaica. ✲

Cretté is a research professor in the department of materials science and engineering and an adjunct professor in the graduate program in historic preservation. She oversees the research team at the WLCC.

ON THE

PULSE

CU ICAR research teams keep industry

moving toward sustainability.

By Leah VanSyckel

Simona Onori works in her CU-ICAR lab on technology geared toward sustainability and energy efficiency.

Inside the Clemson University International Center for Automotive Research (CU-ICAR), the wheels of innovation are carrying the institution into new fields of automotive and transportation technology. Here, students and faculty exist in a symbiotic community where classroom instruction and research go hand-in-hand with development.

In the labs, Clemson professors undertake multidisciplinary research initiatives whose products are revolutionizing the industry. The collaborative nature of the program is an element that Zoran Filipi, chair of the automotive engineering department and executive director of the Carroll A. Campbell, Jr., Graduate Engineering Center, is dedicated to preserving and fostering in CU-ICAR research.

“Using a multidisciplinary approach magnifies the research capability of a group,” explained Filipi. “It also makes us attractive for investment because our teamwork is stable and effective.”

Suzanne Dickerson, director of CU-ICAR’s international business development and marketing, agrees that their cooperative efforts set them apart from other research institutions.

“Even though CU-ICAR is relatively young among the automotive engineering development institutions, its members approach automotive research and development in very progressive ways,” said Dickerson. “Their partners in industry and the students that contribute are from all over the globe, and the curriculum uses a unique model of systems integration — students learn about connections between vehicles, vehicle components, each other, consumers, the environment and other software.”

The connective relationships extend to the engineering faculty, whose research projects have garnered national and international attention. One of these professors is Simona Onori, head of the Battery Aging and Characterization Lab, who conducts experiments on different lithium ion batteries’ chemistry. All of the experiments are on batteries currently used in electrified cars. She hopes to understand and model their chemical behavior to track performance over time.

“This understanding, translated into models, will be used to optimize battery life when used in vehicles,” explained Onori. She works with students and other professors to run her studies.

Onori is also the lead investigator on an initiative sponsored by Fiat-Chrysler Automobiles that studies gasoline particulate filters. They hope to create new control algorithms for vehicles using direct injection in their gasoline engines.

“The new control algorithm we are developing aims to reduce particulate matters, along with reducing NOx, CO2 and hydrocarbons, to meet the new emission regulations imposed by EPA,” said Onori. “There is a significant experimental activity conducted in this project in support of the algorithm development and validation.”

Research projects like Onori’s that focus on sustainability and energy efficiency have become a major focus at CU-ICAR. Federal directives have placed new requirements on automotive technology to make vehicles more environmentally friendly and cost efficient by improving fuel economy and reducing emissions. One of these requirements is that by 2025, automakers must get their fleets of cars and light trucks to an average 54.5 miles a gallon.

Robert Prucka, a faculty member at CU-ICAR, is partnering with Bosch, headquartered in Anderson, S.C., and the U.S. Department of Energy to develop an engine sensor that could improve fuel economy. This EGR sensor, or exhaust gas recirculation sensor, will also reduce the amount of an engine’s carbon emissions.

The EGR sensor will continually measure how much fresh air is mixing with recycled exhaust gas in the engine. Its data will be analyzed by the car’s “brain,” the engine controller, a computer that can adjust the EGR valve as the car drives. That function will allow the car to run better, improving fuel economy by as much as two percent.

Prucka explained the significance of his research: “These changes can sound small, but one percent of the fuel used in the country is a lot of fuel,” he said. “It’s a lot of money. It’s a lot of CO2 emissions.”

While Onori tackles batteries and electric vehicles and Prucka works on engine sensors, Srikanth Pilla leads the way on making cars lighter. Working on a multi-departmental and disciplinary team that includes Paul Venhovens, Gang Li and Melur Ramasubramaniam, Pilla is working to develop lightweight doors made of composite materials that can be used in commercial markets upon completion.

The composites they are testing are ultra-lightweight thermoplastics. Most cars today rely heavily on steel. Some use aluminum and carbon fiber, but those materials can be energy intensive, expensive, or non-recyclable. Pilla’s doors will be both cost effective and recyclable. Current doors weigh in at around 70 pounds. Pilla’s work will lighten them by 42.5 percent — a significant drop in weight that could lead to improved fuel economy. The novelty of his work has earned him attention from both industry and the U.S. Department of Energy. The project received $5.8 million in funding in 2015.

“Of course we care about breakthroughs in basic research, but at the end of the day, we’re interested in the impact we make on industry and society,” said Filipi. “Collaboration makes it possible to make these translations to technology.”

Of course, these three projects represent only a small fraction of the work at CU-ICAR that is making automotive technology better and more sustainable. Elsewhere in the program and at Clemson’s SCE&G Energy Innovation Center in Charleston, research is being done on electric vehicle components such as hybrid powertrains and the connection between transportation and the grid.

“Using a multidisciplinary approach magnifies the research capability of a group. It also makes us attractive for investment because our teamwork is stable and effective.”

—Zoran Filipi

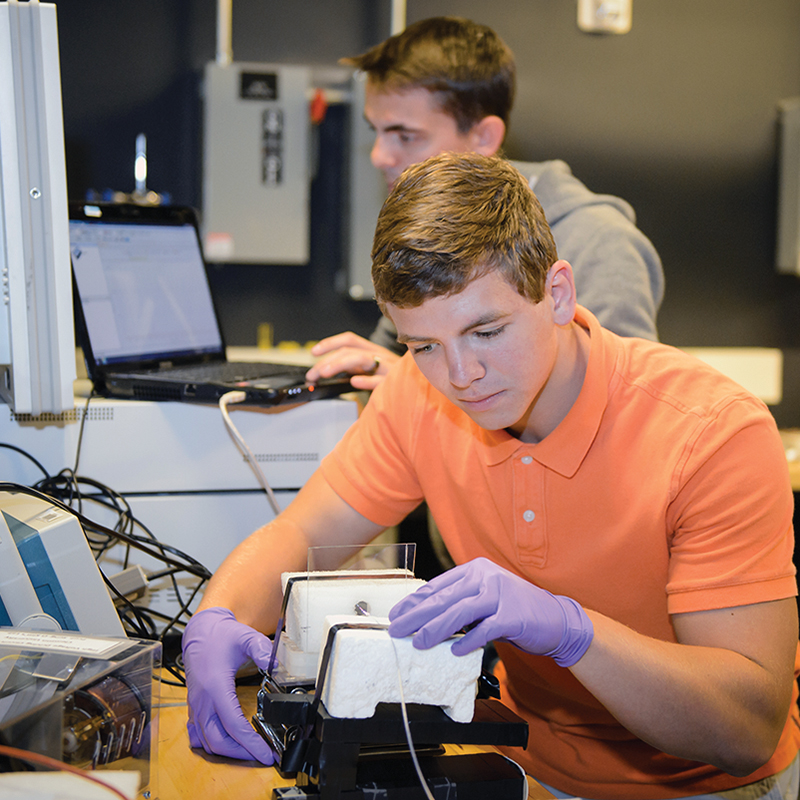

Robert Prucka experiments with a car’s EGR sensor to improve fuel economy and reduce emissions.

Srikanth Pilla works with CU-ICAR students on his project that will lead to lighter doors and better fuel economy.

Although the two centers have not formally cooperated on research projects related to the new fuel guidelines, Filipi hopes collaboration over other endeavors will happen in the next few years.

“I envision seeing the two centers working together, especially as it would be helpful in studying the complex relationship between automotives, energy and storage,” said Filipi.

All of CU-ICAR’s research ties in with its educational goal to produce the next generation of automotive innovators and industry leaders.

“They don’t have a lot of legacy thinking — it’s all fresh thinking. They constantly survey the industry to see what problems they can solve. They are always on the pulse of automotive engineering,” said Dickerson.

That’s why this impressive group continues to emphasize a systems integration approach in their curriculum and encourage diversity in research and researchers.

“It’s good business practice. There’s a direct correlation between diversity increasing and profit increasing,” said Dickerson. ✲

A strategy aimed at expanding graduate and research programs in the college has made progress, and there’s more to come, according to the former chairman of the college’s advisory board.

By Paul Alongi

Ron C. Lindsay completed his two-year tenure as chairman of the College of Engineering and Science advisory board last year and continues to serve as a member of the board.

He was chairman during a transitional time, not only for the college but all of Clemson University. The University’s president and provost and the college’s dean all turned over during his tenure. Anand Gramopadhye began serving as the college’s dean at the midway point in July 2013.

A strategic analysis done at the start of Lindsay’s term found the college had a strong undergraduate program, student experience and individual departments.

But the analysis also started a conversation about how the college could use some of its unique opportunities, especially the innovation campuses, to raise the bar in its graduate program and research effort.

“There’s been good progress so far,” Lindsay said. “There’s a lot more to deliver in the future, but it starts with getting the direction more clear and getting people aligned around that. Dean Gramopadhye has made a lot of headway. There’s still a lot of work to be done and talent that can be leveraged to blow that strategy out and make it real and alive all throughout the college.”

Lindsay said that the new chairman of the board, Michael Watt, is well connected throughout the University, putting him in a good position to carry the strategy forward.

Lindsay, a Greenville native, graduated from Clemson University in 1980 with a bachelor of science in chemical engineering and is now chief operating officer at Eastman Chemical Company.

One of the biggest changes he’s seen since his time as an engineering student is the breakdown of silos between departments. Engineering students are getting a broader education and branching out into other fields, such as accounting and marketing.

It can be difficult with the heavy course loads they face, but diverse experiences equip students to better connect with people who will become their co-workers, Lindsay said.

He noted that students also have more desire for international experience and that they want to find meaning in their work, rather than just have a career.

“Students are graduating with more consciousness about the importance of being able to relate to others well, to understand different perspectives,” he said. “They come out with a better understanding of the value of it and maybe a better understanding of how much further they still need to go as individuals.

“I think there was a lack of realization of that not too many years back. Wanting to make a difference beyond just the financial side is encouraging. I think that’s a challenge for employers. How do you have an experience for these folks coming out of school that plays to that broader interest? I think it’s a very healthy trend.”

Lindsay said that the growing number of international connections in the South are creating new opportunities but also raising questions.

“There’s a challenge,” he said. “Are we going to be able to keep up with the need and bring more of the population along?”

Meanwhile, Clemson will continue to deepen partnerships with technical colleges, local school systems and employers to provide a supportive pathway for students.

“There’s going to be some patience needed,” Lindsay said. “You can’t do it overnight. But it is good to see the recognition and the interest. There is a lot of opportunity, but I think the college has the capability to seize that opportunity.” ✲

News from Around the College

Clean room research leads to ACC honor

Eric Johnson, the PalmettoNet Endowed Chair in Optoelectronics and professor of electrical and computer engineering, has been named an Atlantic Coast Conference (ACC) Distinguished Lecturer…

Clemson University-led team lands grant for sustainability research

Civil engineering associate professor Leidy Klotz and his team received a National Science Foundation grant that will fund research on how property owners, developers…

Clemson University energy research facility wins Global Best Project Award

The SCE&G Energy Innovation Center, a Clemson University facility where researchers work to advance sustainable energy, received an ENR 2015 Global Best Projects Award…

App could fight cyberbullying

Clemson University researchers are building what could be the first app to search photos and videos for signs of cyberbullying as experts grow concerned that defenses are falling short in the face of advancing technology.…

Industrial motor research could dramatically reduce energy use

Clemson University experts are leading a U.S. Department of Energy-funded research project that could dramatically reduce energy consumption worldwide by developing industrial…

Blenner receives NASA Early Career Faculty Award

Mark Blenner, assistant professor of chemical and biomolecular engineering, recently received an Early Career Faculty Award from the National Aeronautics and Space Administration (NASA)…

Freeman Hall addition houses Clemson University’s industrial engineering department

The grand opening of Freeman Hall’s $10-million addition has been hailed as the birth of a new era for Clemson.…

Mark Thies elected fellow of the American Institute of Chemical Engineers

Mark Thies, the Dow Chemical Professor of Chemical and Biomolecular Engineering, has been elected fellow in the American Institute of Chemical Engineers.…

Alumni Spotlight

A DRIVING FORCE

With the opening of the Watt Family Innovation Center on campus, Michael Watt leads the race to preeminence.

By Paul Alongi

Even on the racetrack, Michael Watt keeps his alma mater close. His new Ferrari has a Tiger on the hood, a definition of “what it means to be a Clemson Tiger” on the roof and “All In” across the back. He hired a driving coach and has begun racing, with his first outing at a track near Palm Springs, California.

“For me, it’s a hobby,” Watt said. “But it’s about accomplishment, no different from learning a musical instrument or mastering a new language.”

Just as Watt’s race car carries the name of his alma mater, the Watt name is enshrined on a part of Clemson University. The 70,000-square-foot Watt Family Innovation Center is complete and in use this spring.

Exterior of the Watt Family Innovation Center

The building’s name pays tribute to an extended family that manages a company together, has married itself to Clemson for three generations and has pooled its resources to make the building possible. The family, which includes eight Clemson graduates and one current student, gave $5.5 million to the University in 2012 with all but $250,000 going to the center.

“There are many families at Clemson that have a long tradition of commitment to the University,” Watt said. “I have had the honor of serving on a number of University boards over the last 10 years. Through these interactions I have come to know fellow Clemson graduates who are extremely talented and highly accomplished. They give not only their funds but also their time — their true treasure. It is very humbling to be counted among so many great individuals and families who have given to a cause they deeply believe in — preparing the leaders of tomorrow.”

Engineering has been one of the important ties connecting the Watt family to Clemson since the family patriarch, Dr. Charles Watt, graduated with a bachelor of science in electrical engineering in 1959. The connection remains strong with Michael, the younger of two sons, who serves as chair of the College of Engineering and Science Advisory Board. Michael also serves on the board of directors for the Clemson University Foundation. Further, he is on the Clemson University Research Foundation board and is a fellow of the Thomas Green Clemson Academy of Engineers and Scientists.

In addition to his Clemson service, Michael is chairman and CEO of Scientific Research Corporation, an Atlanta company his father founded in 1988. Michael’s brother, Steve Watt, serves as the company’s executive vice president and chief administrative officer. The advanced technology company provides a wide variety of national defense and global security products and services.

A common theme running through Michael’s life is a passion for technology. He said that when he was an undergraduate, Dr. John Gowdy, a professor of electrical and computer engineering, had a tremendous influence on his life. The passion for technology stuck with Michael long after graduation.

When he returned to campus in the fall for a meeting of the foundation board, the man who races a Ferrari as a weekend hobby showed up in a silver Toyota Prius.

“I’m fascinated by the technological advancements that went into the original design of the Prius,” he said.

Michael’s fascination with technology is reflected in the Watt Family Innovation Center.

Everything about the building is high-tech, from the computer-controlled door locks to the lights that automatically sense when someone is in a room. Haworth, Inc. contributed electronic, moveable walls. Lighting, provided by Philips, has created a “Times Square” feel in the middle of campus.

A collaborative study space in the Watt Family Innovation Center

Interior details are integrated into an open, flexible lobby

“My primary focus in this project has been to join the Clemson family in establishing a well-defined purpose and vision for the building,” Michael said. “My father, along with the faculty and staff of Clemson, deserve the credit for making that vision a reality. He’s the first executive director of the facility. He’s been involved in every detail, including establishing relationships with key industrial partners.”

The Watt-Clemson connection started with Charles, who was the first in his family to graduate from college. He married Linda, a Belton native, who worked for many years as a nurse. Steve was next to arrive on campus. He met his wife, Pam, at Clemson and received his bachelor of science in administration management in 1981. Pam received her bachelor of science in financial management in 1983. They are the parents of two Clemson graduates, Brandon and Brittany. Brandon graduated with degrees in marketing and communication studies, while Brittany earned a degree in nursing.

Michael graduated from Clemson with a bachelor of science in computer engineering in 1984. He met his wife, Kim, at Clemson, and they married after she received her bachelor of science in financial management in 1985. Their older son, Wes, has graduated from Clemson with a degree in political science and currently works in the family business. Their younger son, Austin, is a senior majoring in management, and their daughter, Mary Katherine, is a high school student in Atlanta.

Michael envisions the Watt Family Innovation Center as a place for students to get hands-on experience in technology and innovation. It is serving as a hub for industry to engage with students. It is also enabling students from across the campus, in various disciplines, to collaborate with each other, learning the skills necessary to bring ideas to the marketplace.

Engineering and science feature prominently in the new building, Michael said.

“The objective is to help students take key skillsets out into the marketplace so they can be the innovators and entrepreneurs of tomorrow,” he said. “It’s a privilege to be a part of that.”