Shaping the Future

Clemson University’s engineers and computer scientists work across disciplines and institutions to strategically advance artificial intelligence and prepare the leaders of tomorrow.

IN THIS ISSUE

Research and Innovation in AI

Explore the ways Clemson’s researchers are advancing artificial intelligence.

Collaborations in AI

Highlighting the cross-disciplinary work of Melissa Smith and Brian Dean as well as the college.

Alumni Spotlight

A conversation with 2019 South Carolina Emerging Manufacturer of Year Award winner, Matt Kelley.

FROM THE DEAN

As we begin the second decade of the 21st century, we are also on the cusp of a major revolution, an era that will be shaped in large measure by intelligent systems. From voice-activated assistants to ride-sharing apps, artificial intelligence is already having an impact on our daily lives. However, while these applications are impressive as well as fun, they are just the beginning. Artificial intelligence holds the promise of driving growth in virtually every sector of the economy, accelerating scientific discovery, enhancing national security and improving our quality of life.

As a premier college in engineering and computing, we have a responsibility to conduct the research that both keeps the nation on the cutting edge of artificial intelligence and prepares students for a workforce that will be molded by data and these intelligence systems. But we know that neither of these can nor should happen in isolation. The most significant and impactful work often comes from convergence research that integrates the knowledge, methods and expertise from a variety of disciplines. For artificial intelligence to reach its full potential, such collaboration across disciplines and institutions is key.

This issue of IDEAS features some of the ways the College of Engineering, Computing and Applied Sciences is advancing artificial intelligence in cooperation with leading companies, universities and federal agencies. For example, Feng Luo, a professor in the School of Computing, is currently working on cross-disciplinary research that leverages the power of genomics and bioinformatics to combat a disease that has devastated Florida’s citrus industry.

Mashur “Ronnie” Chowdhury, the Eugene Douglas Mays Professor of Transportation, is using machine learning to develop new ways of protecting self-driving cars from cyberattack, while Amy Apon, the C. Tycho Howle Director of the School of Computing, has used deep learning to create a vehicle-inspection system that BMW has adopted in its plant near Clemson. Hongxin Hu, an associate professor and Dean’s Faculty Fellow of Computer Science, is developing artificial intelligence systems to detect cyberbullying, identify hate speech and keep potentially inappropriate images from reaching the wrong eyes on social media. Melissa C. Smith, associate professor of electrical and computer engineering and director of the Future Computing Technologies Lab, is developing high-performance computing and computer architecture that are being applied to areas as diverse as supply chain inventory control and human gene sequencing.

Furthermore, in this issue, we also focus on how the college is looking to the future. An artificial intelligence summit in November brought together approximately 150 researchers and administrators from Clemson University, the Medical University of South Carolina (MUSC) and Siemens Healthineers to explore collaboration on several new projects. In fact, some of this collaboration has already begun.

Brian Dean, a computer science professor at Clemson, is partnering with MUSC to use artificial intelligence to predict the onset of Alzheimer’s disease. He also serves as one of the coordinators on a new Clemson-MUSC program that offers graduate degrees in biomedical data science and informatics.

While most of this issue focuses on artificial intelligence, we also highlight Matt Kelley, an impressive young alumnus who started his engineering business with a laptop he bought on eBay for $500. Just over four years later, he reports that he has 22 employees, at least $2.4 million in sales and plans to expand his business to a second location. His story underscores how a Clemson engineering degree, an entrepreneurial spirit, passion and hard work can yield exceptional results.

The college is building its future on a foundation of excellence and continuous improvement, and this issue gives you a snapshot of several of our current and future research projects for doing so. As always, I invite you to learn more about our work and to join us in shaping our future together.

Anand Gramopadhye, Dean

College of Engineering and Science

RESEARCH IN AI

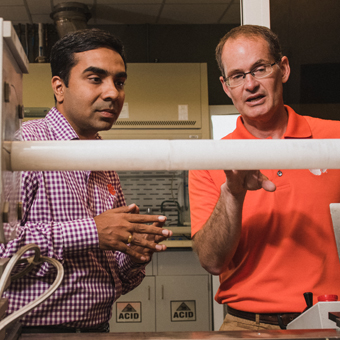

PROTECTING SELF-DRIVING VEHICLES FROM CYBERATTACKS

Hackers around the world have stolen personal information, held data for ransom and in at least one case took an entire nation offline. One of their next targets could be self-driving vehicles.

By Paul Alongi

Hackers around the world have stolen personal information, held data for ransom and in at least one case took an entire nation offline. One of their next targets could be self-driving vehicles.

By Paul Alongi

While self-driving cars are now in the testing phase, they will be hitting the streets in large numbers in just a few years. They will be connected to the internet and will wirelessly communicate with the outside world, according to researchers with Clemson University’s Center for Connected Multimodal Mobility (C2M2).

The technology will improve safety and comfort for the motoring public but will leave the transportation system more vulnerable to cyberattack, researchers said. Everything from the steering wheel and brakes to the GPS and cameras could be targeted.

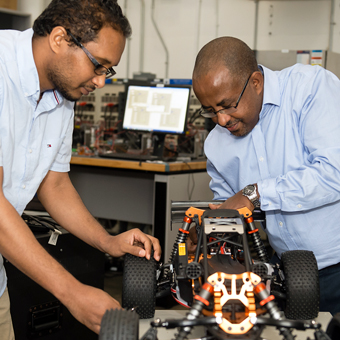

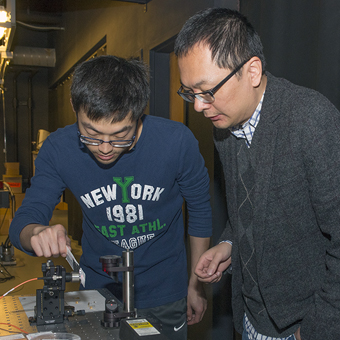

But the vehicles can be protected, and the center’s researchers have started figuring out how, said Mashur “Ronnie” Chowdhury, the center’s director and the Eugene Douglas Mays Professor of Transportation.

“Connected vehicles will make our travel much safer, much more efficient and faster,” he said. “We don’t want these systems to be hacked and be a problem for public safety. Through the research we are doing, we can protect the connected transportation system. We just need to invest our resources and minds into this research.”

Mashur “Ronnie” Chowdhury (right) conducts research in Clemson University’s Center for Connected Multimodal Mobility.

Chowdhury and his team have identified several ways that self-driving vehicles could be hacked, including more than a dozen they described in the fall 2019 edition of The Bridge, a journal published by the National Academy of Engineering.

GPS could be jammed and spoofed. Malware could allow an attacker to gain control of a vehicle. Even something as low-tech as a sticker or a small amount of graffiti on a traffic sign could confuse software.

That’s just to name a few examples, but Chowdhury and his team are developing solutions that give students a chance to work on the cutting-edge of cybersecurity technology.

Zadid Khan, a Ph.D. student studying under Chowdhury, has developed a method to detect and mitigate false-information attacks that could cause a hacked vehicle to hit the brakes when it shouldn’t. Khan’s countermeasure would cut off the attack sources within milliseconds, preventing it from affecting the rest of the network and the wrongful braking.

The research gives Khan a chance to work on machine-learning, data-driven models and software-based networks. The technology, he said, will apply not only to vehicles but also to “smart” roads, buildings and homes.

“In a few years from now, I’ll be able to say it’s here and I had a significant contribution to that,” Khan said.

Chowdhury said that in as little as 10 years, it will be common in some cities for self-driving vehicles to take commuters to work, children to school and shoppers to the store.

He sees self-driving vehicles as moving computers on the roadway.

“In the future, they will be connected to each other and roadside infrastructure, such as traffic signals, and roadside cameras and sensors,” Chowdhury said. “All those connections will provide a huge amount of real-time roadway traffic information with a wide range of benefits.

“Traffic signals, for example, will be optimally timed to reduce stop-and-go traffic. And communication between vehicles will help avoid accidents.

“Even pedestrians will be safer. Cameras at roadway intersections will measure pedestrians’ speed and direction as they cross the street, make predictions about where they will be in the next few seconds and then warn oncoming traffic.”

Traffic deaths nationwide decreased in 2018, but still numbered 36,560, according to the National Traffic Highway Safety Administration.

“The technology will save lives,” said Mhafuzul Islam, a Ph.D. student studying under Chowdhury. “My ultimate vision is to reduce that number through technology so that my work will have an impact on the future.”

C2M2 is a Tier 1 University Transportation Center funded by the U.S. Department of Transportation. ✲

RESEARCH IN AI

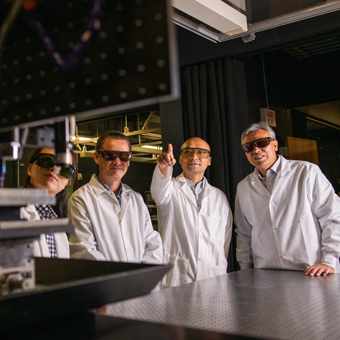

AI ADVANCES MANUFACTURING

Clemson researchers lead the way in the fourth industrial revolution

By Paul Alongi

Clemson University researchers are developing new manufacturing technology that they said will help people do their jobs better and make their work more satisfying, while creating new jobs in fields such as artificial intelligence and robotics.

The research is helping accelerate the globe’s fourth industrial revolution, an era defined by intelligent systems and vast amounts of data.

Clemson is well positioned to help manufacturers adapt to the rapid change. The university has a deep well of faculty and student talent and is centrally located in the Piedmont Atlantic Megaregion, an area stretching from Alabama to North Carolina that has emerged as a national leader in advanced manufacturing.

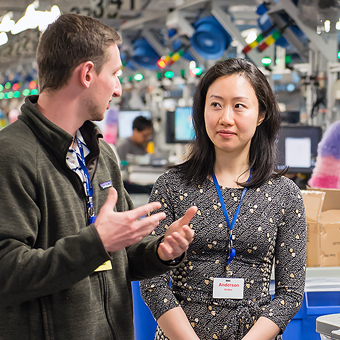

In one of the latest Clemson projects, researchers have worked with industry partners to develop deep stream analysis for a production system that uses high-definition cameras to scan vehicles for faults as they move through the assembly line.

The system employees deep-learning, a type of artificial intelligence, to recognize faults, said Amy Apon, who is leading the Clemson portion of the project and serves as the C. Tycho Howle Director of Clemson’s School of Computing.

The project was motivated by BMW. The company is in full production with an industrialized system at its Greer Plant, and has started rolling out the system at other BMW locations globally.

Inspecting vehicles for defects is usually labor intensive, Apon said. When done manually, workers use complex inspection sheets with each individually built vehicle, a task that machine- and deep-learning can do by interfacing with systems of record, she said.

“One of the advantages of an automated system is that the camera doesn’t get tired,” she said.

“BMW must stay up-to-date with the latest technological advantages and adopt them quickly. Our work with Clemson University helps keep our manufacturing processes on the cutting edge as we strive to raise the bar on the highest standards of quality.”

– Knudt Flor, President & CEO BMW Manufacturing

“You can catch more of the imperfections earlier using a camera-based system than you can with a human inspection system. That has already saved BMW money.”

Knudt Flor, president and CEO of BMW Manufacturing Co., said the automaker’s work on the project is part of its commitment to innovation and growth.

“To stay competitive, BMW must stay up-to-date with the latest technological advantages and adopt them quickly,” he said.

“Our work with Clemson University helps keep our manufacturing processes on the cutting edge as we strive to raise the bar on the highest standards of quality.”

Apon said the methods that BMW and Clemson researchers have developed could apply to different kinds of visual inspection of processes.

“It’s going to make us safer and more secure,” she said “That human who was doing the inspection – there’s still a need for that. And that human will learn how to do other things that will add value to the plant.”

The Internet of People and Things

The internet has allowed robots, other machines and software systems to communicate with each other to improve results, a concept called the “Internet of Things.” Laine Mears, of Clemson University, is working to get humans more involved and make it the “Internet of People and Things.”

Mears, the BMW SmartState Endowed Chair of Automotive Manufacturing, said that he and his team are working to find new ways of gathering data from and feeding information back to human workers.

The team is developing gloves and other wearable devices that capture a range of data on sound, vision, rotation and movement.

The data could then be analyzed to provide workers with instant feedback as they accomplish various manufacturing tasks, such as plugging in hoses and putting connectors together. It could let employees know how consistent they are being and if any connections or operations needed to be verified, he said.

“They will have tangible feedback and elements that they can control in their environment,” Mears said. “We’re even talking about whether we can design machine controllers to stimulate human emotions, so people can enjoy themselves and look forward to coming to work. I think that job satisfaction will translate into a long-term economic benefit.”

Making Work More Enjoyable

Nathan McNeese, an assistant professor in the School of Computing at Clemson, is also working to better integrate human workers with the technology around them. He is working to understand how workers feel about machines and artificial intelligence systems they work alongside.

With that data, algorithms can be created to make the work more enjoyable and effective for people, he said.

“It’s moving beyond where the buttons on a machine go,” McNeese said. “It’s interpreting the behavior humans have when they’re interacting with that interface, because that interface is what they’re viewing as the machine. But it’s not just the design of that interface – it’s so much more than that. It’s evaluating and predicting their perceptions, embodied cognition, and the effective notions that come forth through that interface that make the human feel as though they’re part of that process.” ✲

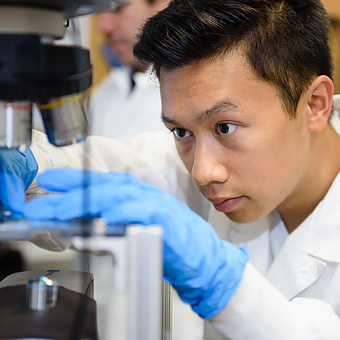

RESEARCH IN AI

A MATTER OF TRUST

Move over R2-D2, because here comes UR5.

By Paul Alongi

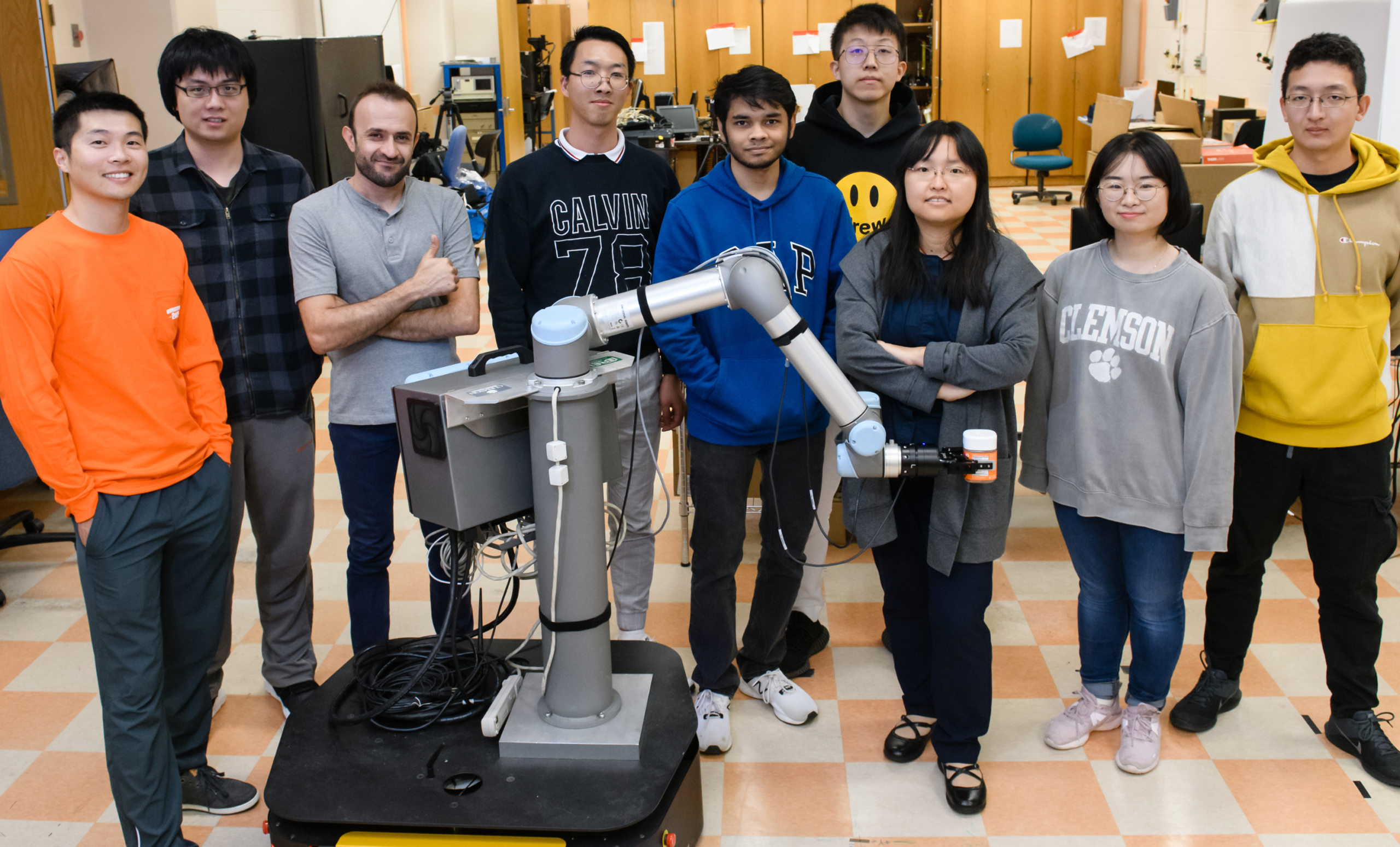

The Star Wars droid is make-believe, but UR5 is a real-life robot in Yue “Sophie” Wang’s lab at Clemson University. She and her team are using the UR5 robotic arm and its mobile base to research how robots and people can better work as a team, like Luke Skywalker and his R2 unit.

The UR5 probably won’t be blasting off in an X-wing fighter anytime soon, but the robot does hold the promise of taking over repetitive tasks in manufacturing. Humans would then be free to focus on the more satisfying work that requires higher-level thinking, skill and dexterity.

But if more menial labor is going to be offloaded to machines, robots are going to have to show they can be trusted to do their jobs safely and effectively.

And that’s the central challenge for Wang and her team.

They designed the UR5 and its mobile base – together called a mobile manipulator – to observe and mirror human actions and to understand human intent. Wang and her team also try to better understand how humans think and make decisions when working with robots.

They collect data and then use machine-learning techniques to build models reflecting how much humans trust their robotic co-workers.

“Understanding that, we can program our robots so that they behave and act in a way that they can better work with humans,” said Wang, the Warren H. Owen-Duke Energy Associate Professor of Engineering.

Wang’s lab is a tech-lovers paradise, packed with various robots, drones and a driving simulator. Students can often be found tapping away at keyboards, their screens filled with code.

Yu “Gloria” Zhang, a master’s student in mechanical engineering, demonstrated the team’s work by standing in front of the UR5 while it held a small jar in its claw-like gripper. Once she raised her arm, the robot moved closer to her. Anytime she waved her arm left or right, the robotic arm mirrored her movements.

“We’re using reinforcement learning to design the robot controller for motion planning,” Zhang said. “It helps the robot make a very human-like motion.”

Wang said that advances in technology could eliminate some jobs, such as those requiring heavy lifting or repetitive tasks. But she also sees a definite need for workers who will understand artificial intelligence and robotics.

“If we want to employ a manufacturing solution on the manufacturing floor, there must be an engineer who can troubleshoot the robot,” she said. “Otherwise, it will not work. Although robots are intelligent, they are not so smart that they can do everything.”

Students who work in Wang’s lab are not only advancing the research. They are also preparing themselves for a future that brings humans and robots closer together.

Maziar Fooladi, a fifth-year Ph.D. student in Wang’s lab, is helping model trust between humans and robots.

“It’s supervisory control,” he said. “When we have a human that is controlling multiple mobile robots like drones or UAVs, we want to know how humans trust individual robots. I’m using machine-learning and deep-learning methods to model trust in multiple agents in a computational way.”

Fooladi’s dream is to work for NASA, which means the robotic technology he is developing at Clemson could one day be headed to the stars.

Just like R2-D2. ✲

Yue “Sophie” Wang (third from right) poses for a photo with the UR5 robot and members of her student research team.

RESEARCH IN AI

SAFEGUARDING REPUTATIONS

Protecting privacy, preventing cyberbullying, and detecting hate speech with artificial intelligence

By Paul Alongi

Maybe the photo shows you in a bar, and your friends from church just wouldn’t understand. Or maybe the picture of you suntanning at the beach reveals a little more skin than you would like your co-workers to see.

Billions of photos have been posted to social media, and some of them can be troublesome or downright embarrassing, especially when shared out of context. They strain relationships, threaten careers and needlessly tarnish reputations.

For Hongxin Hu of Clemson University, it’s a job for artificial intelligence.

Hu and his students are creating an artificial intelligence system, AutoPri, that would be able to automatically detect which photos contain sensitive objects and assign them a sensitivity score. Depending on the score, parts of the photo would be blurred out, or a message could be sent to the social-media user who posted the photo.

Hu and his students are feeding 30,000 photos into AutoPri to train it. Some of the photos were perceived as private by social media users, and some were perceived as public. AutoPri looks for commonalities in each group to learn which objects should be considered sensitive.

When it’s ready to unveil, the system will be aimed at helping protect people who appear in photos but don’t own them.

“The problem with existing social networks is that only photo owners can decide who can see their photos,” Hu said. “But the owners’ friends may not want their images shared. This is what we call privacy conflicts. Different people may have different privacy concerns, even with the same photo.”

“When we detect visual cyberbullying, we give a warning to the users,” Hu said. “We also send a notification to parents and the schools.”

Hu and his team have used the same AI technology to create an app to counteract visual cyberbullying. The app, Bully Defender, could be available in app stores within a year, said Hu, an associate professor and Dean’s Faculty Fellow of Computer Science.

The team has just started collecting data to apply AI technologies to detect hate speech.

With the research, students in Hu’s lab are learning cutting-edge techniques in artificial intelligence.

Nishant Vishwamitra, a Ph.D. student in computer science, has worked with Hu for four years and has had a hand in all three social-media projects. He is starting to decide whether he would like to stay in academia or go out into the private sector after receiving his doctorate.

Either way, he plans to stick with artificial intelligence research.

“What I like best is that we can use AI – a very powerful, emerging technology – to address problems like privacy, cyberbullying and hate,” Vishwamitra said. “The convergence of those is where I love to work.” ✲

RESEARCH IN AI

SAVING ORANGES FROM DISEASE

Artificial intelligence could help save Florida’s citrus industry

By Paul Alongi

One of the world’s most devastating citrus diseases has put farmers out of business, seriously threatened Florida’s second largest industry and resisted all efforts to halt its spread since its discovery 100 years ago.

But the disease, Huanglongbing, has adversaries at Clemson University, and they are bringing a new weapon to the fight.

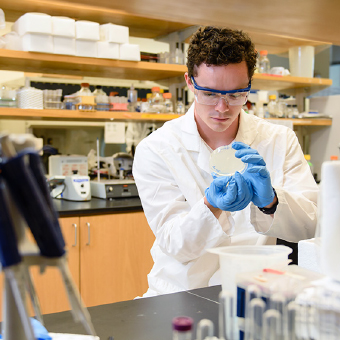

Feng Luo, a professor in the School of Computing, is leading research that uses artificial intelligence to combat Huanglongbing, also called HLB or citrus greening disease.

The goal is to develop new types of citrus trees that will resist the disease for at least 10 years so that farmers can turn a profit.

“Huanglongbing can destroy the whole orange industry,” Luo said. “If there’s no action, there’s no orange trees in Florida anymore.”

The team is part way through a five-year, $4.3-million study that started in 2017 and is funded by the U.S. Department of Agriculture’s National Institute of Food and Agriculture. Luo said that early results have been promising.

Leaves from an orange tree showing the effects of Huanglongbing (Photo courtesy of USDA ARS)

“Huanglongbing can destroy the whole orange industry. If there’s no action, there’s no orange trees in Florida anymore.”

– Feng Luo, School of Computing

“By the end of the grant, we hope to have a very good candidate for trees that can tolerate the disease,” Luo said.

Some diseased trees sprout new branches that have shown tolerance to Huanglongbing, he said. Clemson researchers are using genomics and bioinformatics, both artificial intelligence techniques, to study which genes and pathways make the branches tolerant to the disease.

“If we understand the genes, we can make trees more resistant using gene editing,” Luo said.

Huanglongbing was discovered in southern China in 1919 and has spread quickly in the southern United States since it was first discovered in Florida in 2005.

In a single decade, the disease caused a 72 percent decrease in U.S. production of oranges used for juice and other products, according to a study in the journal Frontiers in Plant Science.

The disease is spread by the Asian citrus psyllid, a winged insect no longer than a grain of rice. The nymphs feed on new shoots and leaves, removing sap from the plant and injecting a pathogen.

The leaves curl and twist, as bacteria hinders growth of new shoots and roots. Once the disease takes hold, the promise of a big, sweet orange ends up small, bitter and lopsided. All citrus trees can be affected, including lemon, lime and grapefruit.

Bo Wu started working on Huanglongbing while a Ph.D. student and has continued as a postdoctoral researcher in Luo’s lab. Wu said the disease evolves quickly but that he likes the challenge.

“My work is to find the mechanism underlying the HLB resistance,” he said. “It feels great, but it is hard work. The mutation is very difficult to identify.”

Other researchers are taking different approaches to combating Huanglongbing, using chemicals and transgenics, Luo said. The advantage to Luo’s approach is that it uses nature’s own solution, he said.

“There would be no regulation problem with our solution,” Luo said. “If we find the tree, we can get it quickly to the farmer.” ✲

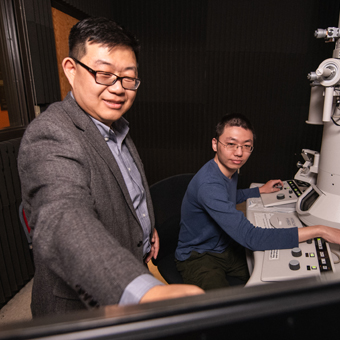

COLLABORATION IN AI

BREAKING BOUNDARIES THROUGH TEAMWORK

By Ron Grant

Futuristic films such as Blade Runner and The Terminator have, for better or worse, played a role in shaping public perceptions of artificial intelligence, often called AI for short. But in reality AI is shaping the present. From manufacturing to bioinformatics, artificial intelligence is positively impacting our lives.

One of those advancing the field of AI is Melissa C. Smith, associate professor of electrical and computer engineering at Clemson University and director of the Future Computing Technologies Lab. Her research group is focused on high-performance computing and computer architecture.

Smith and her team have used their expertise to help BMW manage inventory and to speed up a system that compares genes in healthcare research.

Smith’s involvement in AI, specifically in machine learning, goes back to the early 1990s when she was a research associate at the Oak Ridge National Laboratory. She was part of a group producing an artificial neural network that could detect weld tip failures prior to bad welds on a General Motors manufacturing line.

“Back then the computing devices that we had did not have the horsepower to compute fast enough for real-time diagnostics,” said Smith. “So we actually developed a specific circuit to be able to do that.”

That was an ASIC, which is an Application Specific Integrated Circuit. It was designed to detect the weld tip failures, and that was all that device could do. For real-time processing in today’s world, the instrument of choice is a graphics processing unit. Known as GPUs these programmable chips were originally designed for image processing, but because they perform parallel operations on multiple data sets they are now commonly used for scientific and financial applications that require rapid repetitive computations.

“The interdisciplinary culture in the national labs help make ground breaking discoveries possible,” said Smith. She thrived in the Oak Ridge system, and when she began to look for an academic home, finding an institution with a collaborative environment was key.

“Clemson impressed me with its nurturing environment encouraging interdisciplinary collaboration,” she said. “There are no boundaries between departments and colleges, which provides lots of opportunities to find interdisciplinary collaborators.”

Another plus for Clemson was its Palmetto Cluster, one of the top supercomputers residing at a public university in the United States. The Palmetto Cluster makes use of more than 23,000 central processing unit cores and over 1,100 GPUs, and can complete trillions of mathematical operations per second. Operated on a democratized condominium model system, any Clemson faculty, staff or student can register for an account and use the Palmetto Cluster free – a perk that gives Clemson faculty and students a distinct advantage.

One of Smith’s early projects in machine learning and AI at Clemson involved a collaboration with industrial partner BMW. In a large manufacturing operation it is critical to maintain inventory and location of various components so they can be obtained very quickly to keep the production line running. At that time BMW associates would go around and scan bar code labels on boxes to determine the location of parts in the factory. Smith’s research group developed a reader that ran on an iPhone that allowed employees to walk around and automatically identify a bar code in the image, scan that bar code and put that information into a database with the location of the part.

With the iPhone barcode reader an associate can also drive through the BMW trailer yard on a golf cart and scan a number off a trailer and the number off the parking space, correlate that information and know exactly where a single part is before it goes into the factory. Eventually plans call for putting the reader on a drone that could be flown through the plant or the trailer yard and automatically track and update part locations, thereby improving the manufacturing process.

When Smith began to seek out interdisciplinary faculty collaborators at Clemson she met Alex Feltus, a professor in genetics and biochemistry. Their 10-year partnership has been remarkably productive and recently resulted in a large National Science Foundation grant to improve cyberinfrastructure across the nation for scientific data analysis at scale (SciDAS).

“Clemson impressed me with its nurturing environment encouraging interdisciplinary collaboration. There are no boundaries between departments and colleges, which provides lots of opportunities to find interdisciplinary collaborators.”

– Melissa Smith

One of Smith’s research team members, Ph.D. candidate Ben Shealy, developed an interest in some of Feltus’ research.

“Where we were working with image data, Dr. Feltus was working with genetic data – gene sequencing,” said Shealy. “In the same way you can use a neural network to tell the difference between a picture of a dog and a picture of a cat, you can use those same tools to differentiate between healthy human tissue and cancerous tissues.”

In one of the Feltus/Smith experiments, Shealy was using KINC (Knowledge Independent Network Construction) – a data mining tool that looks at relationships between different pairs of genes. By incorporating a GPU, he was able to achieve a remarkable 500-times speedup over existing KINC software. This means that an operation that previously would have taken 500 days, by using Shealy’s methodology, the same operation can now be completed in one day.

The process was described in a paper published by IEEE Access, a multidisciplinary, applications-oriented, archival journal that presents the results of original research or development across all of IEEE’s fields of interest.

When Shealy completes his graduate work he plans to pursue a career doing the kind of work he does now, tackling difficult problems that require weeks, months, even years of research. Just like Smith, his mentor, he wants to learn from people from multiple disciplines.

“We take the expertise and knowledge that we have about different machine learning techniques, deep learning approaches and apply them to other domains,” Smith said. “It’s exciting to be able to seek out new opportunities that are not the mainstream, but revolutionary.” ✲

COLLABORATION IN AI

ARTIFICIAL INTELLIGENCE SUMMIT

South Carolina’s leading research universities team up with industry to improve health care

by Paul Alongi

Some of South Carolina’s top researchers are exploring new ways they can work together to improve health care with artificial intelligence, an effort that is starting with pilot projects but could grow into a major collaboration.

The Artificial Intelligence Summit on Nov. 21 in Columbia brought together about 150 officials from Clemson University, the Medical University of South Carolina and Siemens Healthineers.

Most were researchers who came from a wide variety of backgrounds, ranging from radiology to psychiatry and bioengineering to computer science. They met for nearly six hours in The Palmetto Club about a block from the Statehouse.

The idea was to get the researchers together so they could learn about each other’s work and spark ideas for new projects.

The provosts from the two universities each put up seed money to fund pilot projects that resulted from the summit. It’s just a start, they said, as officials from the two universities continue talks aimed at establishing a larger partnership in artificial intelligence.

Robert Jones, the executive vice president for academic affairs and provost at Clemson, described artificial intelligence as a recent and rapidly growing phenomenon with capabilities to dramatically improve health care.

“Because it’s so interdisciplinary, Clemson is extremely interested in developing strong partnerships internally and externally,” Jones said. “We can think of no better partners than the Medical University of South Carolina and Siemens.”

Lisa Saladin, the provost at MUSC, said that artificial intelligence is the leading technology that will transform health care.

“The impact on health care is just beginning,” she said. “We have the potential to totally transform the way we provide care, the way we diagnose patients and how we intervene to make sure the right patients are getting the right treatment at the right time.”

Clemson and MUSC reside on opposite ends of the state but have a long history of collaborating on research, especially in bioengineering.

Several Clemson faculty members and students work in the Bioengineering Building on MUSC’s campus in Charleston. The universities collaborate on two separate Centers of Biomedical Excellence funded by the National Institutes of Health.

Both institutions already have a variety of artificial intelligence research underway.

Clemson researchers are developing artificial intelligence to protect privacy on social media, inspect cars on assembly lines for defects and help save citrus trees from an incurable disease, just to name a few examples. Some of the Clemson research is enabled by the Palmetto Cluster, one of the nation’s fastest university supercomputers.

MUSC is primarily using two types of artificial intelligence tools, predictive analytics and natural language processing, Saladin said. Researchers are using the tools to develop techniques that can help diagnose and treat a range of ills, including cancer, Alzheimer’s disease, substance abuse, child abuse, epilepsy, aphasia, inflammatory skin conditions and cardiac issues, she said.

Mike Farrell, the vice president of enterprise services at Siemens Healthineers, said that he saw tremendous opportunity to bring together Clemson, MUSC and Siemens Healthineers to improve health care.

“What I’m most excited about is how we can take these great ideas from bench to bedside,” he said. “We’re developing a digital ecosystem, so if there’s an application, an algorithm, or a tool that’s being developed and validated, you would have an easy way to commercialize it. We could bring it not just to MUSC patients but to the world.” ✲

COLLABORATION IN AI

ALZHEIMER’S AND AI

Brian Dean brings his passion for computer science to new partnerships with MUSC

by Paul Alongi

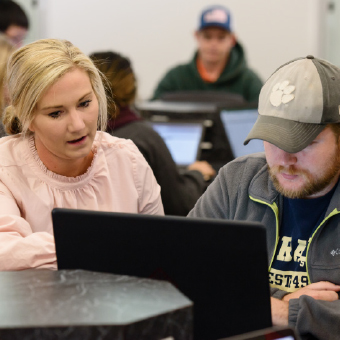

Brian Dean of Clemson University is working closely with the Medical University of South, Carolina, conducting research and helping coordinate a graduate degree program, as the two institutions strengthen ties to improve health care worldwide.

The research is aimed at using artificial intelligence to predict the onset of Alzheimer’s disease. Dean, a computer science professor, also serves as one of the coordinators on a new Clemson-MUSC program that offers graduate degrees in biomedical data science and informatics.

His work with MUSC places him at the center of a burgeoning partnership between Clemson and South Carolina’s largest medical university. The two institutions have long-standing collaborations in bioengineering and are in talks to expand to other areas.

“Collaboration between institutions and disciplines is the future,” Dean said. “Computer scientists have to work with people in other domains, and other domains are becoming more dependent on advanced computation and artificial intelligence to innovate with huge data sets.”

For the research project, Dean’s collaborators are taking MRI scans of people’s brains, some with Alzheimer’s disease and some without. The challenge for Dean will be to train an artificial intelligence system to discern the difference between the two.

“In about one year, things get real for me because they’re going to hand me a mountain of data and basically say, ‘See if you can develop any meaningful predictions based on the data that we have,’” Dean said. “That’s when it gets more stressful from my perspective, but also a lot more fun.”

Dean has started preparing. He’s reviewing literature to see what techniques other researchers are using, and he’s had a Ph.D. student graduate with a dissertation based on the project.

“We realized right off the bat that the data sets are so big that we’re going to need brand new algorithms to process them,” Dean said. “We came up with new algorithms that are waiting to be used when the data comes in.”

Jane Joseph, a professor of neuroscience at MUSC, said that Dean is crucial to the research.

Brian Dean, a professor of computer science, says “collaboration between disciplines and institutions is the future.”

“He brings impeccable credentials and deep experience to the team,” she said. “He never turns down a challenge, and his passion for computer science research and education is palpable. It’s a pleasure to work with him.”

Brian Dean also serves as a graduate program coordinator on a new Clemson-MUSC joint program that offers master’s and Ph.D. degrees in biomedical data and informatics.

The program targets traditional students and working professionals. They are advised by faculty members at both universities. Classes are taught in Clemson and Charleston and connected via video link. The first cohort of graduates are on track to complete their degrees in fall 2020.

Both universities bring their strengths to the program. Clemson is contributing the technical expertise in computation, engineering, mathematics and statistics, while MUSC brings clinical, medical and biological expertise

“Putting those together I think is going to be a very strong program that’s going to lead to a lot of innovation,” Dean said.” ✲

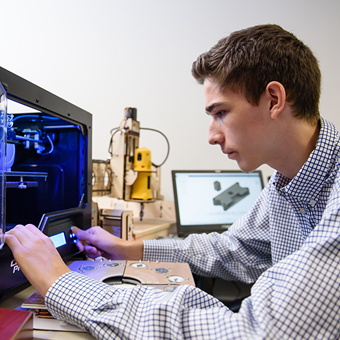

ALUMNI SPOTLIGHT

A DREAM AND A LAPTOP

By Paul Alongi

Clemson University alumnus Matt Kelley started his engineering business in a room above a detached garage with a laptop he had bought on eBay for $500.

He had no customers, no employees and no equipment, but he had a dream and the drive to turn it into reality.

Little more than four years later, Kelley Engineering has 22 employees, a freshly renovated shop, 30 pieces of equipment, at least $2.4 million in sales this year and plans to expand to a second location.

“It’s definitely humbling,” said Kelley, who received his Bachelor of Science in mechanical engineering in 2007. “We started the business four years ago with a hope and a dream, and now it’s grown like wildfire to where we are today. It’s really a testament to the team we have built here.”

South Carolina’s government and business leaders are taking notice.

Gov. Henry McMaster recently presented Kelley Engineering with the 2019 South Carolina Emerging Manufacturer of the Year Award. Kelley Engineering also won the 2019 Employer Impact Award from Anderson County Economic Development.

The company is standing out as manufacturing surges in South Carolina. The sector employs about 255,800 people in the state, a nearly 24 percent increase from a decade earlier, according to the U.S. Bureau of Labor Statistics.

Kelley Engineering designs and builds custom automation equipment. The company also provides CNC machining and metal fabrication services to a wide variety of industries across the Southeast.

Kelley said the company’s team of engineers gives them a competitive advantage.

“There aren’t many machine shops and fabrication shops that have engineering support to come alongside a customer and solve problems,” Kelley said. “We have a lot of customer engagement because they value our engineering team’s role in designing effective solutions, managing build projects, and serving as a technical resource to the manufacturing team.”

Kelley is one of two Clemson-educated mechanical engineers at the company. Michael Spiers, who was the company’s third employee, was still a student when he started working for Kelley as part of Clemson’s Cooperative Education Program.

He left Kelley Engineering when his rotation in the program was over and returned to Clemson to finish his degree. When Spiers graduated in May 2018, he went back to Kelley Engineering to launch his career.

“A degree from Clemson gets you connections,” Spiers said. “What you learn in school is one thing, but I think what you take with you from your time at Clemson is more important–the connections you make, the career path you choose, what you do with what you learn.”

Kelley grew up a Tigers fan in Anderson, graduated from T.L. Hanna High School and always knew he wanted to go to Clemson.

Mechanical engineering seemed a natural fit. While growing up, he enjoyed working on cars and lawnmowers and was intrigued by concepts in physics, such as force, torque and stress.

“We started the business four years ago with a hope and a dream, and now it’s grown like wildfire to where we are today.”

– Matt Kelley

“My Clemson degree is probably the biggest contributor to my success,” Kelley said. “I meet engineering grads from Clemson everywhere, whether it’s the insurance guy, a banker, a customer, a supplier, or a future employee. Clemson engineers are in every industry out there. A lot of them are in engineering, but they go on to do all sorts of stuff.”

Kelley graduated right before the Great Recession and landed a job with a company that designs and builds automation equipment. He worked there for eight years and gained valuable experience in design and management but still remembered the dream he had years earlier.

“Sitting in the Cooper Library my last couple years at Clemson, I’d think, ‘Man, I’d like to have my own engineering firm one day,’” Kelley said.

He took the leap in October 2015, but success didn’t come for him overnight.

Kelley renovated a room above the detached garage at his Greenville home so he would have a place to meet with customers. By January 2016, he was ready to start telling them his story. He networked any way he could, including with cold-calls, emails and LinkedIn.

“The first year I got more no’s than I could possibly recount,” Kelley said.

Kelley stuck with it, landed a few projects and made some capital investments. He bought a milling machine, an engine lathe, a bandsaw and a mig welder. In those early days, Kelley did virtually everything himself.

“I’d order the material, I’d machine it, I’d weld it together, I’d paint it and I’d deliver it,” he said. “I did that for about a year. When I got some bigger projects, I’d have some guys come in and do subcontract work for me.”

Kelley’s garage started to fill up, and his business needed more room so that he could build bigger equipment for his customers. The commercial real estate around his home off Pelham Road was too expensive, so he started looking in Anderson County.

Kelley found a building on Highway 17 in Piedmont that had been vacant for years and needed some love but had the much-needed square footage. He bought and renovated it.

When Kelley Engineering moved to Piedmont in May 2017, the business consisted of Kelley and three part-time employees. The number grew to four full-time employees by the end of 2017, then tripled to 12 full-time employees by the end of 2018 and hit 22 by November 2019.

Employees described Kelley as an insightful, helpful and “hands-off” manager.

“He gives you room to grow and make your own mistakes,” said Travis Middleton, the company’s fabrication manager. “It can be a blessing or a disaster sometimes, but we learn from our mistakes. I think we’ve all grown so much as individuals and as a team.”

Shane Langley, the company’s machining manager, said that Kelley never discourages employees from learning new skills.

“I could say, ‘I want to go over there and have Travis show me how to weld or run one of the machines,’” Langley said. “Matt is never going to stop anyone from learning new stuff, and I think that’s important.”

Kelley said people learn best from their mistakes.

“We’re not allowing people to make big mistakes, but we definitely want them to have the freedom to be creative and try new things and to drive to better themselves,” Kelley said.

When he started the business, Kelley set a goal of $250,000 in sales the first year, $500,000 in the second and $1 million in the third. He fell $30,000 short his first year but surpassed his second-year goal, hitting $715,000.

“In the third year, we did $1.4 million,” Kelley said. “Then people said, ‘What are you going to do next year?’”

The goal for 2019 was $2.4 million, and while final numbers weren’t available, the company has definitely hit the mark, Kelley said.

The growth has once again created a need for more space. Kelley Engineering is in the process of closing on a building three miles away from its current location and plans to move its fabrication operations there, Kelley said.

Kelley Engineering also recently received AS9100 certification, which is of significance to suppliers who do business in the aerospace industry.

Kelley’s household has been growing, too. When he first started the company, Kelley and his wife, Meg, had one son, Micah who was then 6 months old and is now 4 and a half. They have added two more sons, Miles, age 3, and Mason, who is 9 months.

Kelley said that Meg, who holds undergraduate and master’s degrees in nursing from Clemson and works as a nurse practitioner, has played a big role in his success.

“My wife has been the biggest believer in me,” he said. “I would not be here today without her beside me, encouraging me and pushing me.”

Kelley said that if he has any advice for students it would be that experience and hard work are keys to his success.

“One thing I tell people is that you may not be the smartest, but you can outwork everybody around you,” he said. “That’s one thing you can control. If you want to be good, if you want to be better than other people in your field, outwork them.” ✲

News from Around the College

Clemson University cited in national report that focuses on crafting America’s science and engineering enterprise

The United States faces an urgent shortage of skilled technical workers, according to a new National Science Board report that cites a Clemson University center, CA²VES, as an example of how partnerships could be part of the solution.

Darnall W. & Susan F. Boyd Foundation help freshmen thrive in engineering

The new Boyd Scholars program at Clemson University gives qualifying freshmen a chance to ease into the challenging math courses that are part of the engineering curriculum.

Clemson University collaborates on project that could make the internet faster and more secure

Sudeep Popat, an assistant professor of environmental engineering and earth sciences, has launched a new research project, feeding human waste to microbial fuel cells that produce hydrogen peroxide.

Sensor research underscores Clemson University’s leadership in technology for extreme environments

Clemson University researchers are developing three new sensors designed to withstand two of humanity’s harshest environments, the intense heat inside power plants and the tremendous pressure at the bottom of hydraulic fracturing wells.

Jacob Sorber named Fulbright scholar

Jacob Sorber, a Dean’s Professor of Computer Science, is teaching and conducting research in Botswana this academic year, an opportunity made possible by an award from the Fulbright U.S. Scholar Program.

Civil engineering’s Master of Engineering program celebrates first graduates

Nine professionals who enrolled as part-time students are the first recipients of the Master of Engineering Risk Engineering and Systems Analytics. Graduates traveled from across North America and from as far away as India to participate in the August commencement ceremony.

New funding will increase the number of South Carolina biomedical researchers and advance tissue-regeneration research

The National Institute of General Medical Sciences is providing $5.7 million to the South Carolina Bioengineering Center for Regeneration and Formation of Tissues.

Green energy gets a boost at Clemson University’s Wind Turbine Testing Facility

Clemson University researchers based in North Charleston have received $1.24 million from the U.S. Department of Energy to develop a new way of testing a key piece of equipment on offshore wind turbines.

Simulator could help Future vascular surgeons improve their surgery skills

An important part of medical school could soon be upgraded for the digital age, as a group of Clemson University researchers develop the first simulator of its kind to help teach future vascular surgeons how to suture blood vessels.

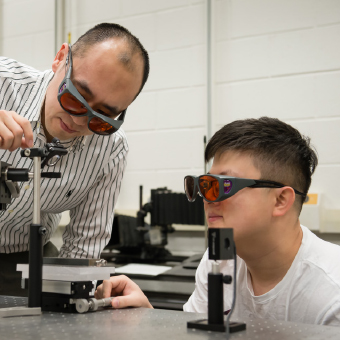

MIT and Clemson University team up to close the education gap in photonics manufacturing

Students and technologists across the country will soon have a new and interactive way to learn about manufacturing the light-based technologies that are crucial for a host of next-generation products and services, including high-speed wireless networks.

Ph.D. student receives Hitachi fellowship for her work to make large batteries more efficient

Clemson University Ph.D. student Allison Domhoff has received a $25,000 Hitachi High Technologies Electron Microscopy Fellowship to support research aimed at making energy grid-scale batteries more efficient and cost-effective.

Leadership comes into focus as Martine Laberge Wins service award

Martine LaBerge, who has led the bioengineering department for 17 years, recently received the inaugural Herbert Voigt Distinguished Service Award. The honor recognizes her extraordinary service to the discipline through volunteering and leadership.

Clemson associate professor Mary E. Kurz receives Class of ’39 Award for Excellence

Clemson University faculty have recognized Associate Professor of Industrial Engineering Mary E. Kurz as one of the very best among them by awarding her the Class of ’39 Award for Excellence.

Jorge Rodríguez reaches 5,000 students with EXPLORE Mobile Lab

Rodríguez, a research assistant professor in the College of Engineering, Computing and Applied Sciences, is on a mission to educate middle school students across the Palmetto State about the critical and growing field of engineering.

Spinning electrons could help computers run faster

New research is putting Clemson University at the forefront of an emerging technology that could help computers run faster and use less energy, while allowing them to continue shrinking in size.

Two professors elected fellows of the American Association for the Advancement of Science

John Ballato and Marek Urban were honored during the association’s annual meeting in Seattle.

Kyle Brinkman lauded for research achievements and service to profession

Brinkman, the chair of Clemson’s Department of Materials Science and Engineering, will be recognized as a Brimacombe Medalist by The Minerals, Metals & Materials Society.

Rocket Woman

Clemson University alumna Vanessa Wyche, deputy director of NASA’s Johnson Space Center in Houston, is playing a critical role in the upcoming Artemis program, NASA’s 2024 directive that will see astronauts set foot on the moon once again.

Yunyi Jia wins top honor for young engineering educator

An assistant professor in automotive engineering at Clemson University, Yunyi Jia, is receiving the Ralph R. Teetor Educational Award from SAE International. This award recognizes him as one of the nation’s top young engineering educators.

College honors endowed chairs

Three College of Engineering, Computing and Applied Sciences faculty members have been named to endowed chairs.

Clements, McKissick and Gramopadhye among region’s most influential

Three Clemson University officials made Greenville Business Magazine’s list of the 50 most influential people in the region. They were President James P. Clements, Chairman of the Board of Trustees E. Smyth McKissick III and Dean of the College of Engineering Computing and Applied Sciences

Anand Gramopadhye.

Spotlight

Graham Montgomery (left) and Michael Stoner conducted some of the nation’s first research on mass timber, a building material that is touted as an environmentally sustainable alternative to concrete and steel. When they started their research in 2013, mass timber had been used in Europe for years but was just starting to catch on in the United States. Montgomery was a master’s student, and Stoner was an undergraduate, both in civil engineering at Clemson University. Fast forward to fall 2019, and Clemson opened its first mass-timber building, the Snow Family Outdoor Fitness and Wellness Center. Montgomery is now mass timber technical director for Swinerton, a general contractor construction company. He oversees Stoner, who works part-time at Swinerton while pursuing his Ph.D. in civil engineering at Clemson.

Ratan Tata’s visit inspires students

The world-renowned industrialist, innovator, visionary and philanthropist, visited the Clemson campus to participate in President James P. Clements’ inaugural Global Leaders Forum. Several Tata Fellows had a chance to personally thank him and join other students in seeking his perspective on global impact, philanthropy and business. Tata was the chairman of the Tata Group, a Mumbai-based conglomerate. The Tata Group of Companies is the leading corporation of India and has more than 90 operating companies in 80 countries and 395,000 employees worldwide.