Renewable Lignin Biofuel from an Industrial By-Product Stream

Significant Greenhouse-Gas Reductions are Possible

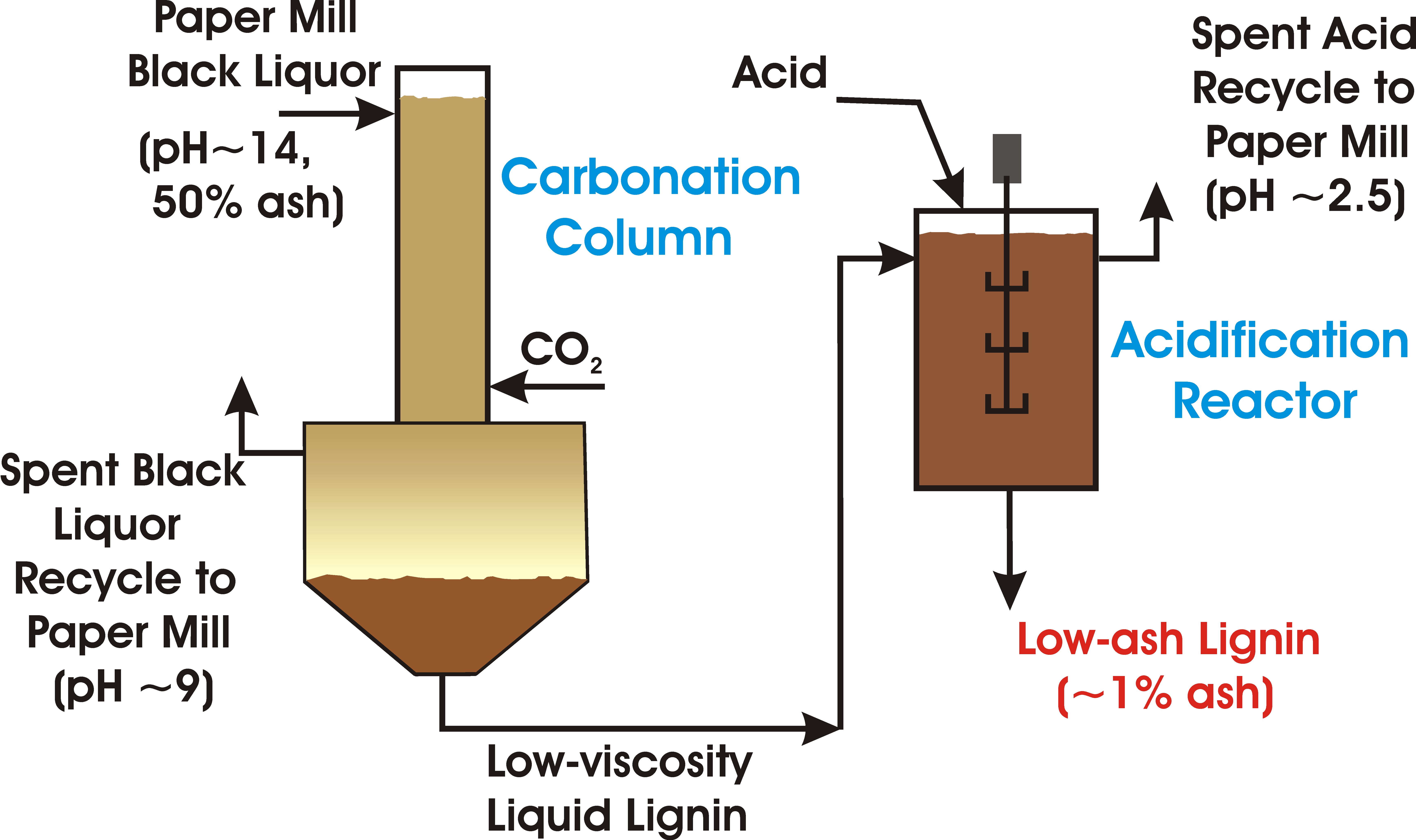

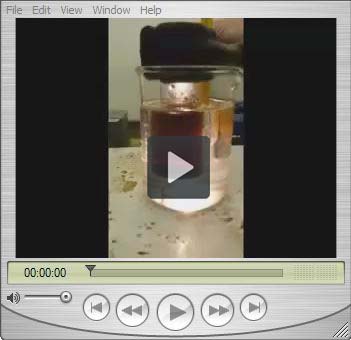

Our academic/industry team has discovered that lignin can be precipitated from paper-mill black liquor in the form of a low-viscosity, easy-to-process liquid by contacting the black liquor with carbon dioxide gas. We call this precipitate liquid lignin. This unique liquid-liquid phase behavior (see the video) is a central feature of the so-called SLRP (Sequential Liquid Lignin Recovery and Purification) process that we are developing (see Figure 1) for generating a clean-burning, low-ash lignin. This renewable biofuel would be used as a direct replacement for coal in electric- power plants. Significant reductions in coal consumption and greenhouse-gas production would result. Other envisioned applications include as renewable phenolic and epoxy resins.

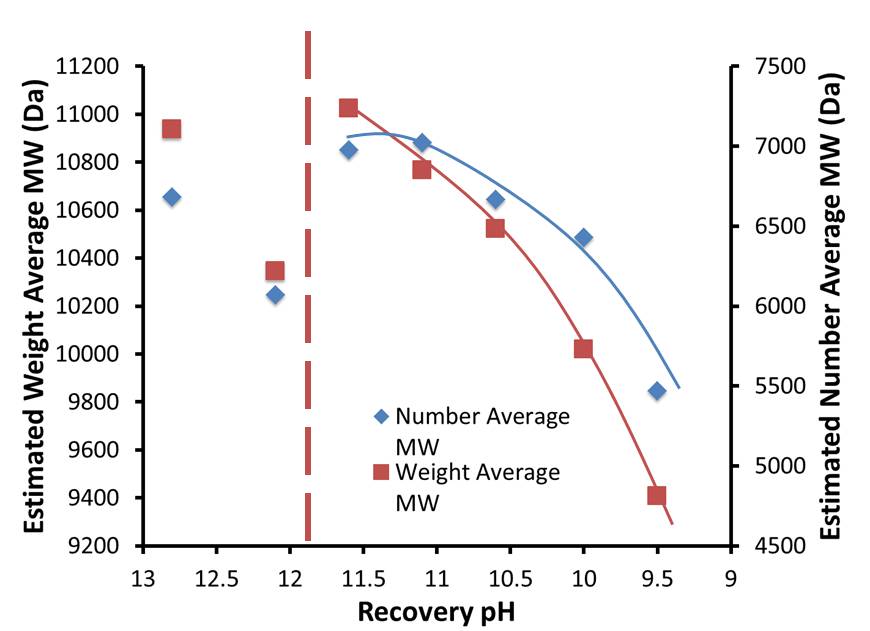

Figure 1. The SLRP process for producing lignin biofuel. Figure 2. Mol wt of lignin controlled by SLRP pH

The underlying fundamentals of the formation of the liquid-lignin phase, along with an elucidation of its bulk and molecular properties, are also being investigated. In particular, we are determining the effect of SLRP operating parameters on product yield, product purity, and chemical and oligomeric composition. For example, Figure 2 shows how the molecular weight of the liquid-lignin phase can be controlled by adjusting the pH of the carbonation column. The interrelationship between product purity (i.e., ash content), molecular weight, and phenolic content is important for assessing the ultimate application for the various types of liquid-lignin fractions that can be produced via the SLRP process.

Watch video showing the liquid-lignin phase.

Collaborators

John Blackburn and Michael Lake Liquid Lignin Co.

Alex Briseño UMass Amherst

Robert Enick Pittsburgh

David Hodge Michigan State

Wes Hoffman AFRL

James Klett ORNL

Amporn Sane Kasetsart Univ.

Jeremy Smith ORNL

Jim Watkins UMass Amherst

Alex Briseño UMass Amherst

Robert Enick Pittsburgh

David Hodge Michigan State

Wes Hoffman AFRL

James Klett ORNL

Amporn Sane Kasetsart Univ.

Jeremy Smith ORNL

Jim Watkins UMass Amherst

Funding Sources