Purification and Fractionation for making Ultrapure Lignin

A biorenewable polymer with a range of applications

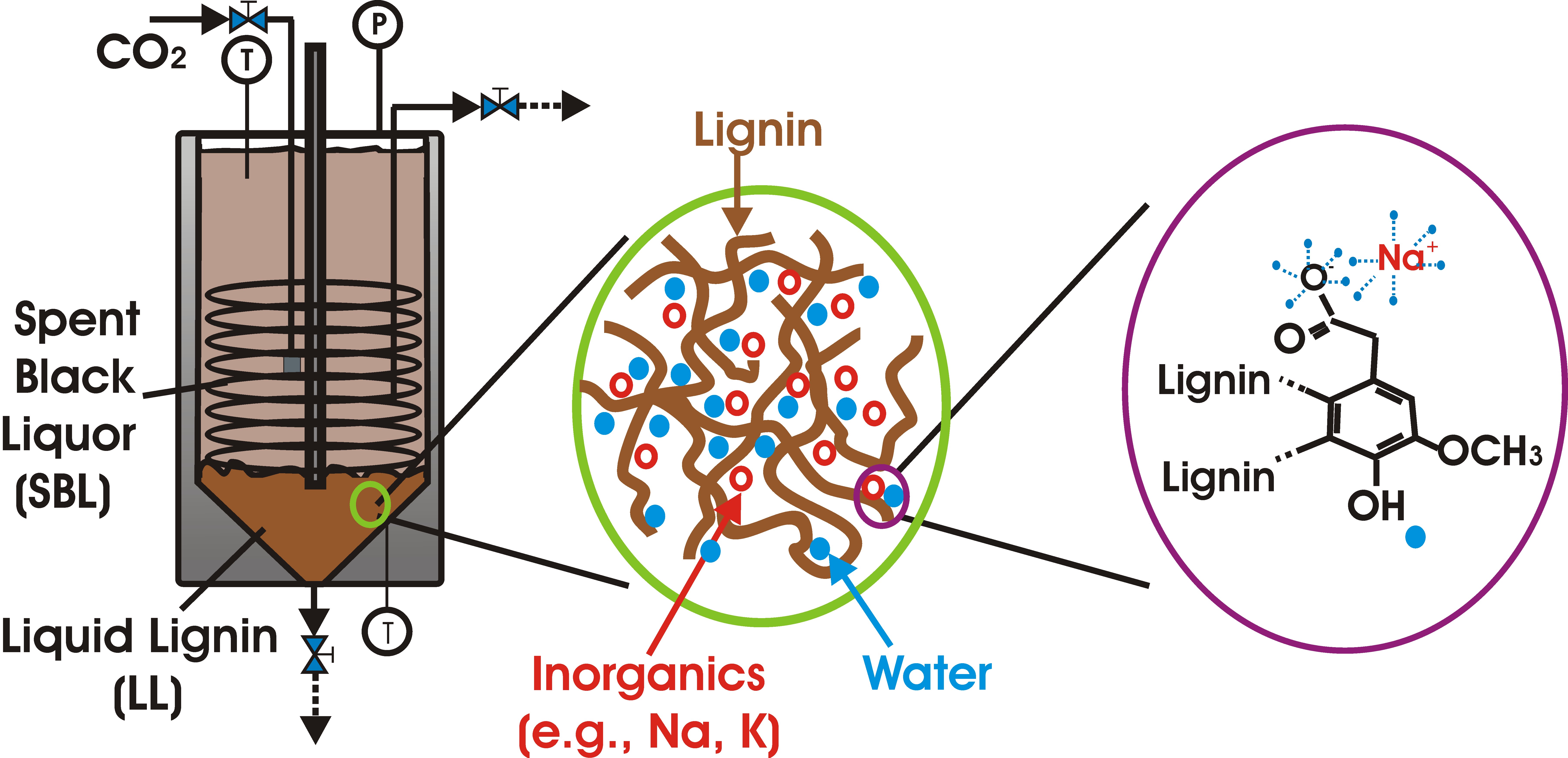

Lignin is one of the most common organic compounds on earth (only cellulose is more abundant), and is a major by-product (50 million tons/yr!) of the Kraft process for making paper. Unfortunately, only about 0.2% of that lignin is recovered for non-fuel uses, because the metals content of Kraft lignins (2-4%) is too high for processing into value-added products with significant societal impact. However, if Kraft lignin could be converted into an "ultrapure" form via a cost-effective process, its tremendous potential as a renewable biopolymer would be unleashed. For example, the development of an appropriate ultrapure lignin that would serve as an inexpensive precursor for the production of carbon fibers for automotive composites would be transformative.

Watch video showing formation of the liquid-lignin phase upon heating.

Thus, the Thies group is working on separation processes for the purification and fractionation of Kraft lignins, with the goal of achieving key metals contents of less than 100 ppm. This would represent a several hundred-fold reduction in the metals content of a typical, commercially available Kraft lignin.

Watch video showing formation of lignin filaments upon drawing.

Collaborators

John Blackburn and Michael Lake Liquid Lignin Co.

Alex Briseño UMass Amherst

Robert Enick Pittsburgh

David Hodge Michigan State

Wes Hoffman AFRL

James Klett ORNL

Amporn Sane Kasetsart Univ.

Jeremy Smith ORNL

Jim Watkins UMass Amherst

Alex Briseño UMass Amherst

Robert Enick Pittsburgh

David Hodge Michigan State

Wes Hoffman AFRL

James Klett ORNL

Amporn Sane Kasetsart Univ.

Jeremy Smith ORNL

Jim Watkins UMass Amherst

Funding Sources