Reinforced-Concrete

Buckling-Restrained Brace for Precast

Concrete Lateral-Load-Resisting Frames

Sponsor: National Concrete Masonry Association

Foundation(NCMA Fdn)

Students: Shreedhar KC and Aakash Basu

Collaborators:

Overview

We are testing the short and long span masonry beams with different parameters to accurately determine the modulus of rupture values (MOR) values of masonry beams so that we can make strong recommendations for incorporating these values in upcoming TMS code. Detailed and experimentally validated numerical analyses (discrete element models, DEM for unreinforced member behavior will supplement the experimental data to allow for the extrapolation of the experimental findings to a larger range of variables. The parametric DEM analyses will allow us to compute the statistical sensitivity of the results to change in each parameter and therefore help determine any reduction/safety factors that should be included in the adoption of the findings in the masonry code and standards. The validated DEM approach will also allow for numerical examinations of additional configurations for beam reinforcement beyond the geometries and reinforcing layouts tested in this program.

Accomplishments

So far, we have tested the short span beams(single course unreinforced and reinforced) with varying parameters as well as bond wrench tests at the Built Environment Lab (BEL) at Clemson. At Concrete Masonry and Hardscapes (CMHA) lab, we have already tested 4 sets of large span multicourse reinforced beam during my internship. Meanwhile, I have presented part of my research work at the 15th Canadian Masonry Symposium at Ottawa, Canada (Jun 2-5) and won “The H. W. H. West Award” for the best overall paper with a Graduate Student as the Lead Author.

Ongoing Work

We are now gearing up to wrapping these tests with last set of beams which will be constructed and tested within next 2 months. Aakash is working on the Discrete Element modeling of the beams and the DIC to expand the beam dataset.

Reinforced-Concrete

Buckling-Restrained Brace for Precast

Concrete Lateral-Load-Resisting Frames

Sponsor: National Science Foundation

Students: Eddie Lewis, Grace Putman, and Bella Cantillo

Collaborators: University of Notre Dame (PI: Dr. Yahya Kurama), Clemson University (co-PI: Dr. Laura Redmond), and University of California San Diego (co-PI: Dr. Jose Restrepo).

Overview

This project is a collaboration effort whose main goal is to design, model, and analyze a precast concrete buckling restrained brace (BRB) member. This would be done on both a specimen-level and a frame-level. Additionally, the Clemson team focuses on the educational outreach aspects of this project. This project concerns a BRB frame for a precast concrete system. This can allow for more customizable dimensions, and it would potentially be possible for producers to manufacture these frames in the plants.

A BRB is a lateral load resisting system that is characterized by yielding steel core encased in a concrete brace. This configuration allows for the steel core to be restrained when the brace enters into compression. When the steel core is restrained, buckling is prevented which can allow for the full use of the tensile and compressive strength of steel, and thus a more even dissipation of energy is achieved. This project concerns a BRB frame for a precast concrete system. This can allow for more customizable dimensions, and it would potentially be possible for producers to manufacture these frames in the plants.

Accomplishments

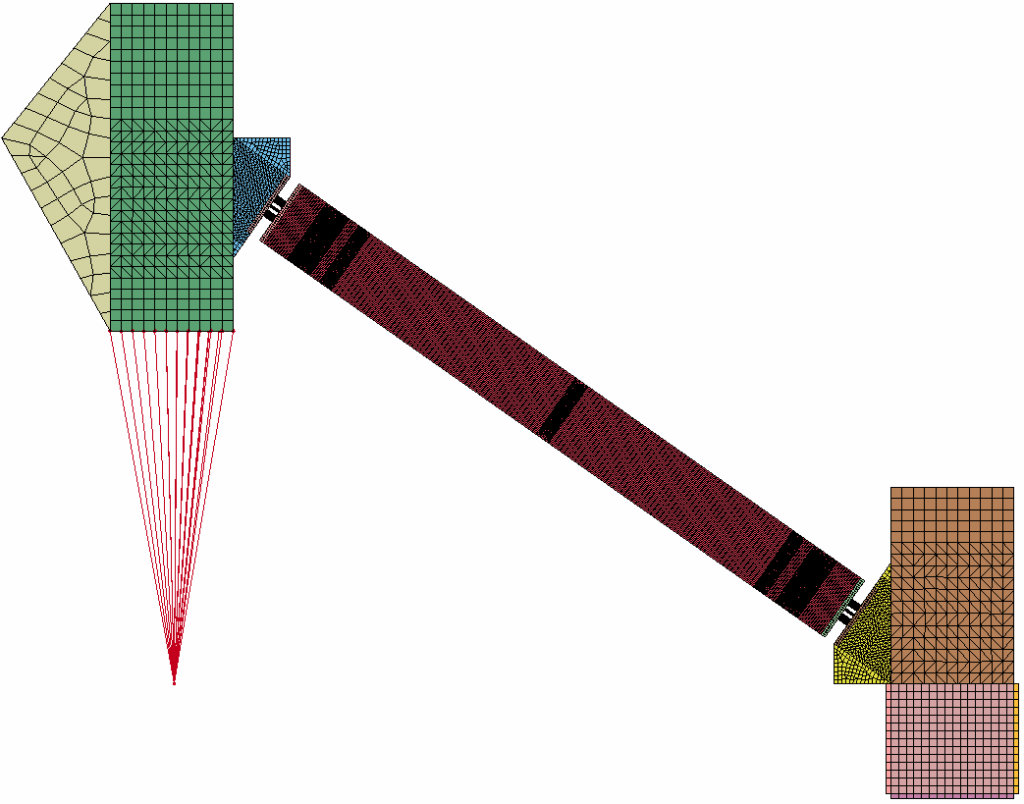

Through this project, there have been multiple rounds of specimens produced, and with each round of specimens, more knowledge and understanding of the complications are understood. The main regions we focus are with the connection of the brace to the corbel/column region. This is because when the BRB was first introduced it was for a steel frame system. On the modeling side of things, we have been able to model the specimen-level test. Once the high fidelity models are calibrated, the goal is for the models to be able to assist with informing and guiding the design of the BRB specimens. An example of the specimen-level model is pictured here:

Ongoing Work

Current work is being done to show how the increasing fidelity of the model can allow for the capturing of more failure modes. Additionally, a series of models are being constructed and ran to help determine future BRB specimen choices. It should be noted that there are currently four main objectives from the modeling standpoint:

- Be used to calibrate simplified frame element models for system-level analysis.

- Verify models can capture required failure modes.

- Inform future element test specimen designs.

- Examine phenomena that cannot be tested at University of Notre Dame (the location of the specimen-level tests).