Electronic Ignition

by Adarsh Appukuttan, Clemson Automotive Engineering Graduate Student

- Basic Description

-

The ignition system is an integral part of the internal combustion engine. In modern vehicles, ignition systems are sub-systems of the engine management systems. The ignition system creates the spark that ignites the fuel-air mixture in each cylinder of the engine. The spark is created by an extremely high voltage at the tip of the spark plug when the piston is at the end of the compression stroke. Ignition systems have evolved over the years from magneto systems to digital electronic systems. Magneto ignition systems are the simplest form of ignition systems. They evolved into switchable systems and battery-operated systems. Ignition systems can be mechanically timed, electronic or digital electronic systems.

Mechanically timed ignition systems make use of breaker points which are subject to mechanical wear due to constant movement. They are also worn out by oxidation and burning at contact surfaces due to constant sparking. The points require regular adjustment due to wear and it also causes poor sparking which leads to lower engine efficiency. The introduction of electronic ignition system solved these issues.

In electronic ignition systems the breaker points are replaced by a crankshaft position sensor and a semi-conductor switch. The output from the sensor triggers the switching device to switch a large current through the coil. Since this system lacks moving parts it is much more reliable compared to mechanical ignition systems.

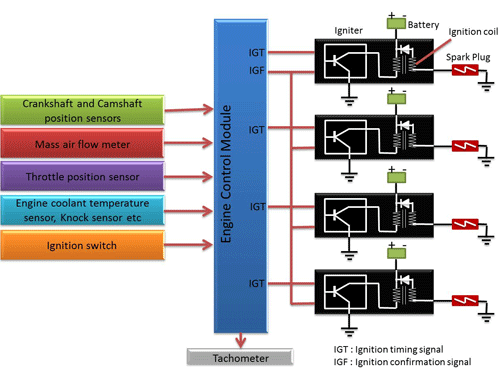

In an electronic direct ignition, data from the various sensors in the engine are continuously sent to the engine control module (ECM) and the ECM calculates the ignition timing and transmits the ignition signals to the igniter. The ignition timing (IGT) is calculated constantly according to the conditions of the engine. These calculations are based on the ideal ignition timing values that are stored in the ECM in the form of electronic spark advance maps. Based on the signal received from the ECM, the igniter turns the primary coil current on and off at the optimal time. When the current to the primary coil is cut off, a very high voltage is generated across the secondary coil. This high voltage when applied to the spark plug generates a spark inside the cylinder. When the ECM cuts the current to the primary coil, it receives an ignition confirmation signal (IGF) from the igniters for each cylinder. The electronic timing method offers a much higher precision and greater flexibility than mechanically timed ignitions, thus facilitating an improved fuel economy and power output.

- Sensors

- Hall effect sensor, Crankshaft/Camshaft position sensor, Knock sensor, Optical sensor, Throttle position sensor, Barometric sensor, Temperature sensor, Mass air flow sensor, Engine coolant temperature sensor

- Actuators

- Spark plug, Ignition coil

- Data Communications

- Control Area Network (CAN) bus data communication between ECM and ignition system

- Manufacturers

- Delphi, Bosch, Denso, Boyer Brandsen, Newtronic

- For More Information

- [1] Ignition System, YouTube, Jan. 17, 2009.

- [2] Ignition System, Wikipedia.

- [3] How Automobile Ignition Systems Work, Howstuffworks.com.

- [4] A Short Course on Ignition Systems, Familycar.com.

- [5] Electronic Spark Advance, YourOnlineMechanic.com.

- [6] Ignition System Functions, YouTube, Mar. 20, 2009.

|