A Traction Control System is used to prevent wheel spin from occurring due to acceleration. This usually happens on a slippery surface, such as snow or a pool of water, where the wheels are not able to generate enough traction to move the vehicle. Traction Control systems and Anti-Lock braking systems (ABS) are often paired together as they help improve the vehicle's stability with by working in tandem. The major difference between an ABS and a Traction Control system is that while ABS stops the wheel from spinning while braking, Traction Control stops the wheel from spinning while the vehicle is accelerating. A Traction Control System is also known as an Anti-Slip Regulation (ASR).

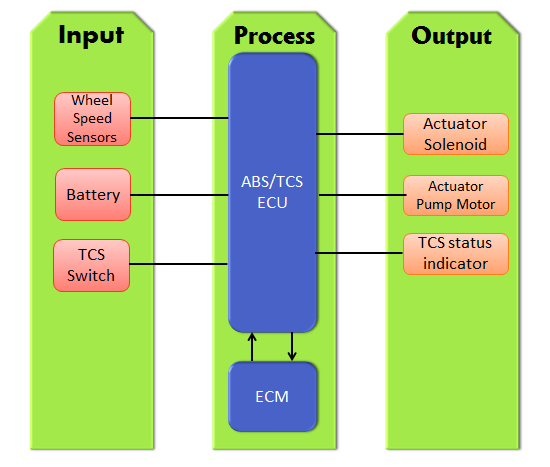

The Traction Control system (TCS) uses wheel speed sensors to measure the vehicle's speed with the rate at which the drive wheels are spinning, to detect if there is any slip occurring between the tire and the road. If a slip is detected between the road and the wheel, the Traction Control system ensures that only the minimum amount of torque is supplied to the slipping wheel to generate the required amount of friction for the vehicle to move.

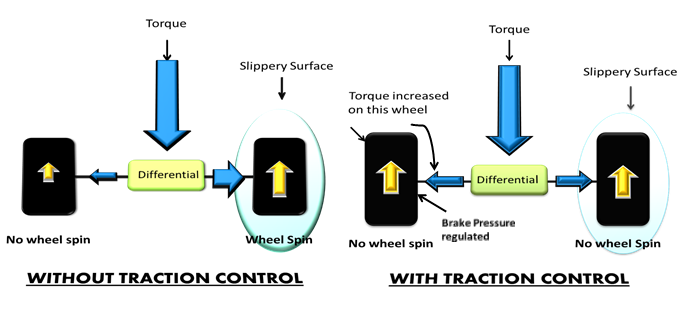

The primary input of the TCS is the wheel speed sensor. These sensors continuously monitor the speed of each driven wheel and send the data to the ABS and Traction Control System ECU. When a slip is detected between the tire and the road, the TCS regulates brake pressure on the slipping wheel. This process of slowing down the wheel helps it regain traction. Simultaneously, torque is shifted through the differential to the opposite wheel that has a better traction when compared to the slipping wheel.

The brake pressure is applied by routing the pressure from the ABS pump and through the ABS modulator. The pressure to applied is regulated through a high pressure accumulator. The TCS includes an extra solenoid valve in the ABS modulator, for each individual drive wheel's brake circuit. This arrangement allows the system to apply brake pressure to slow down the spinning wheel in order to regain traction. The continuous usage of brakes in TCS generates a lot of heat in the brake calipers. To prevent overheating of these calipers, TCS automatically discontinues after a certain length of time.

If both the driven wheels are losing traction, the TCS slows both the slipping wheels equally to slow them down until they regain traction. Otherwise, the systems send a signal to the Powertrain Control Module (PCM) to reduce the engine torque to the wheels until traction is regained.

When the TCS is activated in a vehicle, it is shown to the driver through the instrument cluster. In a lot of performance vehicles, there is an option of switching on/off the Traction Control System. When this system is disabled, a warning light glows to notify the driver that the TCS is switched off. Switching off the TCS does not switch off the ABS in the vehicle, even though they are inter-related.

BOSCH invented the Anti-Lock Braking system in 1978 and the Traction Control System in 1985. Traction Control is used in cars as well as bikes [1].