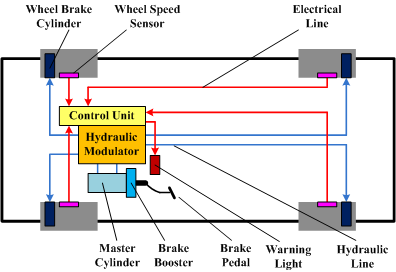

Antilock Braking Systems (ABS) prevent wheel lockup by modulating the braking pressure. These systems play a significant role in improving the safety of modern vehicles. Braking hard, particularly on ice or wet roads, can cause one or more wheels to lock and skid over the surface. This can result in longer stopping distances or even a loss of steerability. ABS systems monitor the wheel speed in real time and regulate the brake pressure automatically in order to prevent wheel lockup and improve the driver's control of the vehicle. They are now often paired with other systems such as Electronic Brake-force Distribution (EBD), Electronic Stability Control (ESC) and Traction Control to further increase vehicle control and driver safety. The main components of these systems include regular brake parts (such as the brake pedal, hydraulic cylinders and lines), wheel speed sensors, and a hydraulic modulator operated by an electronic control unit. The architecture of the ABS system (including the hydraulic modulator) is illustrated in the figure below.

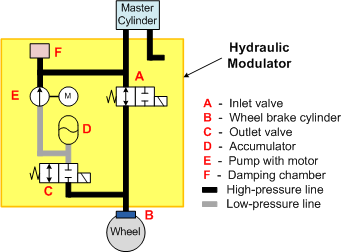

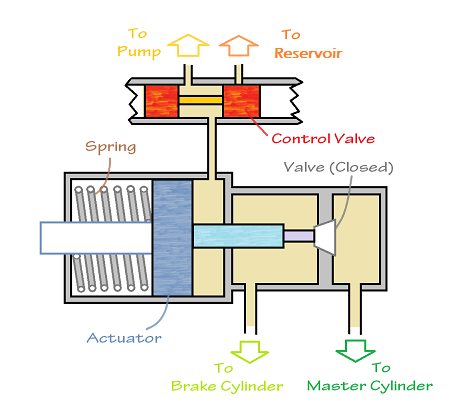

When operating in normal conditions, the outlet valve (C) of the hydraulic modulator is closed and the inlet valve (A) stays open until the pressure reaches the desired value. Then both the inlet and outlet valves remain closed to hold this pressure and provide sufficient brake torque for wheel brake cylinders. Once the control unit detects any excessive wheel slip, the corresponding outlet valve is opened to release the pressure to the accumulator (D) and prevent possible wheel lockup. The excess brake fluid is returned to the master cylinder through the return pump (E). After the wheel slip returns to normal, the valve solenoids are de-energized and the hydraulic modulator resumes the regular braking process.

Antilock braking systems can be classified based on the number of channels and number of sensors employed.

Four Channel, Four Sensor ABS - This type of ABS uses a speed sensor and separate valves for each of the four wheels. Maximum braking force is achieved with this type.

Three Channel, Three Sensor ABS - The front wheels each have a sensor and a valve. There is one valve and one sensor for both the rear wheels.

One Channel, One Sensor ABS - One valve and speed sensor located on the rear axle monitor both the rear wheels. This type of ABS is commonly seen in pickup trucks.

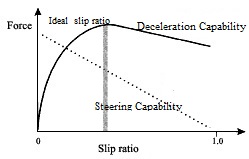

Slip Ratio

Slip ratio is a means of calculating and expressing the locking status of a wheel. It is the ratio of the difference between the vehicle speed and the wheel speed to the vehicle speed. For example, when the vehicle is running normally on an ideal road surface, the slip ratio is 0; when the wheels are locked, the slip ratio is 1. During braking, as the slip ratio rises, the ABS system maintains an ideal slip ratio of 0.10 to 0.30 based on the road-tire friction characteristics. In this way, the vehicle maintains a maximum deceleration without a total loss of steering capability.

ABS systems are required on vehicles sold in Europe. They are also required on trucks and buses sold in the U.S. Although ABS systems are not explicitly required on cars sold in the U.S., they are found on virtually every new car due to the fact that the U.S. requires electronic stability control (ESC) systems. Cars with ESC systems have computer controlled braking for each individual wheel; therefore implementing ABS on a car with ESC is relatively easy and inexpensive.