The purpose of an ignition system is to ignite the compressed air-fuel mixture in the engine combustion chambers. It delivers an electric spark that jumps a gap at the two ends of the spark plug. The heat from this arc ignites the air-fuel mixture, creating pressure that pushes the piston down the cylinders so the engine runs. There are two main types of ignition systems: Contact-point ignition systems and Electronics ignition system.

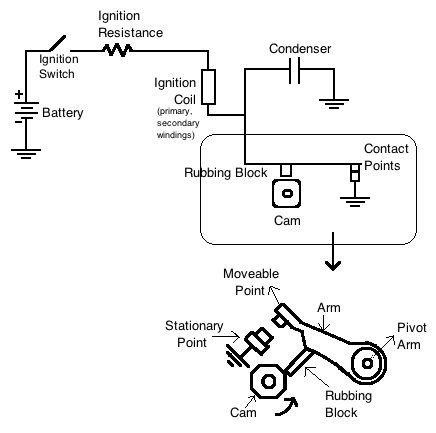

Contact-point ignition systems:

The ignition switch connects the ignition coil to the battery when the ignition key is turned on. The ignition coil is a step-up transformer that raises the battery voltage to a high voltage that may reach about 25,000 volts. In some electronic systems, they might go as high up to 47,000 volts or higher. The high voltage causes sparks that jump the gaps at the spark plugs. The ignition distributor does two jobs: First, its set of contact points act as a fast acting switch which produces a high voltage surge. Second, it distributes the voltage surge in the correct firing order. The spark plug has two electrodes positioned to form a gap, over which the spark jumps to ignite the fuel-air mixture.

The system consists of two circuits; the primary and secondary. When the key is turned ON, which connects the battery to the circuit, the contact points close and current flows through the primary winding. This produces a magnetic field around the primary windings in the coil. As the cam rotates, it swings the arm on a pivot as the cam lobes push on the rubbing block. When the contact points open, current flow stops and the magnetic field collapses. As it collapses, it cuts across the thousands of turns of wire in the coil secondary. This produces a voltage in each turn. These add together to produce the high voltage delivered through the secondary circuit to the spark plug.

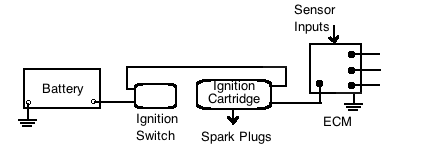

Electronic ignition systems:

Contact points systems were eventually done away with because they wear out over time. Electronics ignition systems do not use contact points, they have transistors, instead that act as an electronic switch that turns the coil primary current on and off. They are similar to contact breaker ignition systems but there is an electronic control unit which replaces the points. Today's systems employ a capacitor-ignition system that stores primary energy in a capacitor or condenser. In a CDi system, the spark occurs when a switch or transistor closes the primary circuit. Then a charged capacitor discharges through the ignition coil. This produces a high voltage surge and creates a spark. Each spark plug has its own capacitor and ignition coil. They all fit into an ignition cartridge that mounts over the spark plugs. The ECM controls ignition timing based on signals from the crankshaft/camshaft position sensor. The manifold-absolute pressure sensor, knock sensor gives information to the ECM about the conditions of the engine load, detonation etc. Based on all this information, the ECM triggers the proper coil to fire at the proper time.