LIN specifications were developed by the LIN consortium, which was founded in the late 1990s by a group of five automotive manufacturers, including BMW and DaimlerChrysler. The purpose of this consortium was to develop a low-cost master/slave interface for controlling simple sensors and actuators in automobiles. The LIN bus is generally cheaper than the CAN bus to implement.

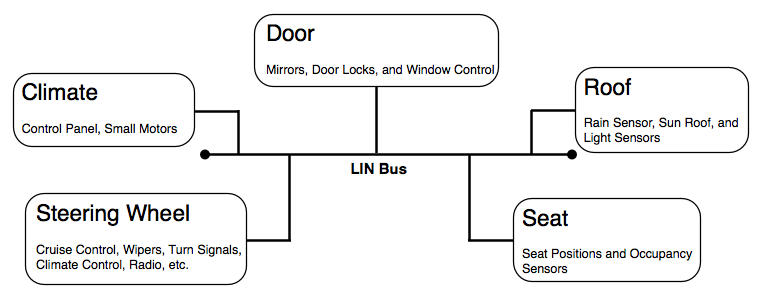

A small and relatively slow in-vehicle communication and networking serial bus system, LIN bus is used to integrate intelligent sensors and actuators, such as air conditioning systems, door locks, and seat motors. The LIN bus is most useful when controlling systems that don't require very much information too quickly.

A primary advantage of this bus is that it can be implemented with a single wire (using the vehicle chassis as a current return path). The system can only send one command over the line at a time. The maximum command size is 8 bytes, which can be transmitted every 10 ms, but commands of 2 bytes or 4 bytes can be sent every 5 ms. The LIN bus can also communicate over a vehicle's power distribution system with a DC-LIN transceiver.

The LIN Bus uses a master/slave interface. The master sends out a message identifying the slave, and the slave responds. Slaves can only respond when the master sends out a call for a response, and each slave has a unique identifier.

The consortium released Version 1.1 in 1999. The current version is 2.2A.