Fluid Level Sensors

- Basic Description

-

Automobiles with an internal combustion engine use a

fluid level sensor to monitor the amount of fuel in the fuel tank.

Some vehicles use fluid level sensors to determine when fluids such as

washer fluid, coolant or brake fluid are getting low. Some fluid level sensors employ

floats that move up and down with the fluid surface and use

position sensors to produce an output relating to the

position of the float. Another popular technique for detecting fluid levels is to

monitor the capacitance of a rod inserted in the fluid. As more fluid surrounds the rod,

the capacitance increases. Ultrasonic fluid level sensors work like

acoustic distance sensors that monitor the distance

between the tank wall and the fluid surface. In fluids that must be isolated from the

surrounding environment, optical sensors can be used. In these types of sensors, a laser

or LED produces light that is detected on the opposite end of the fluid tank.

The amount of light reaching the sensor is inversely proportional to the amount of

fluid in the tank.

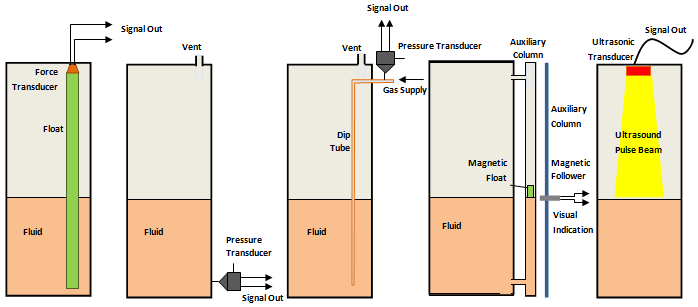

Different methods for measuring fluid levels in a tank.

Design Variations

Float Switches - These sensors employ a magnetic float that moves with the liquid surface, actuating a hermetically sealed "reed switch" in the stem. This simple and comparatively low-maintenance design installs readily; minimizes shock, vibration, and pressure; and works with a variety of fluids.

Non-Contact Ultrasonic Sensors - These fluid-level sensors employ ultrasonic distance sensors to measure the distance from the surface of the fluid to the top of the tank.

Contact Ultrasonic Sensors - These sensors use a low-energy ultrasonic device which measures the presence or absence of liquid at a certain point. When the fluid is in contact with the sensor, the ultrasonic signal is attenuated which triggers a relay.

Capacitance Level Sensors - Capacitance sensors sense a change in the capacitance that occurs between two conductors when a fluid is present. Like ultrasonic sensors, there are contact capacitance sensors that detect the presence or absence of a fluid at a point; and non-contact level sensors that detect the level of the fluid as determined by the continuously varying value of capacitance as the amount of fluid between the plates changes.

- Manufacturers

- ABB, Bourns, Continental, CTS, Deeter, Delphi, Denso, Electrosense, Fluid Switch, Gems, Gill, GSI Automation, Honeywell, Methode Electronics, McLaren Electronics, Molex, MTS, Nippon Seiki, Omega, PKP, Senix, SensorTechnics, Siemens, SSI, Standex-Meder, TI Automotive, WEMA

- For More Information

- [1] Level Sensor, Wikipedia.

-

[2] A Dozen Ways to Measure Fluid Level and How They Work, Sensors Magazine, Dec. 1, 2004.

- [3] DIY: Fuel Level Sensor/Sender Replacement, Audizine.com, Forum Audi B7 A4 Tech, August. 21, 2009.

- [4] Fuel Level Senders - The Inside Story, Samuel Jaslyn, Ezine@rticles.

- [5] Process Level Measurement, Sensorland.com.

- [6] Selecting a Fluid Level Sensor: What You Need to Know, Carolyn Mathas, Digikey TechZone, Mar. 15, 2012.

- [7] How Capacitive Liquid Level Sensors Work, YouTube, May 30, 2013.

- [8] ECE 470 Final Project: Fuel Tank, David Cantrell, YouTube, Apr. 24, 2015.

|