Variable Valve Timing

by Wangxiang Xie, Clemson Automotive Engineering Graduate Student

- Basic Description

-

Valve timing has a direct effect on the intake/ exhaust phase of the internal combustion engine, it has crucial influence on the engine’s dynamic performance and fuel economy. Unlike conventional fixed valve system, VVT technology takes engines speed and load as inputs and changes the valve timing correspondingly under different work conditions.

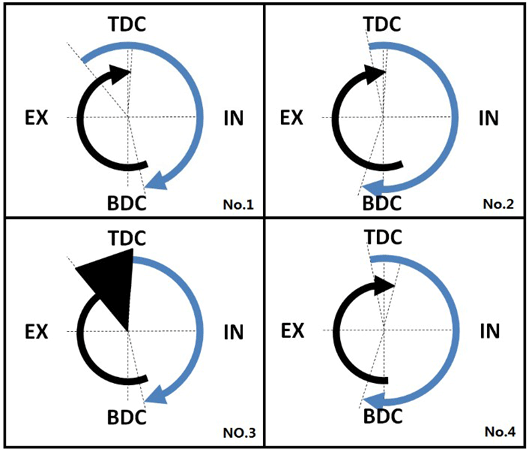

Low speed high load conditions: Under low speed high load condition, the engine should increase its intake advance angle in order to have a better dynamic performance. When the engine is running at a low speed, the air in the intake manifold has relative low inertia, backflow of cylinder gas into the intake manifold are like to occur at the end of intake phases due to the high pressure in the cylinder. VVT system closes the intake valve in advance to suppress this kind of backflow, as shown in Figure No.1.

High speed high load condition: When the engine running under high speed high load condition, the air in the intake manifold has relative high speed and inertia, the VVT system postpones the close of the intake valve to magnify the amount of air that flows into the cylinder, as shown in Figure No.2. This change in valve timing provides improves the engine’s dynamic performance.

Partial load condition: when the engine is running at partial load, VVT system raises the engine’s EGR rate to improve the emission performance. And the VVT system also minimizes the pumping loss during the intake phase to optimize the fuel economy. To achieve these two purposes, the VVT system open the intake valve in advance to create a bigger valve overlap, as shown in Fig-3

Low temperature start and idling condition: VVT system diminish the valve overlap during idling and low temperature start, as shown in Figure No.4. When the engine is idling, the vorticity in the cylinder decreases. VVT system postpones the open of intake valve so there will be a bigger pressure difference between the intake manifold and the cylinder when the valve is opened. This results in better combustion in the cylinder. This is also the solution for low temperature start.

- Sensors

- Crankshaft Position Sensor, Throttle Position Sensor, Fluid Pressure Sensor

- Actuators

- Hydraulic, pneumatic or electromagnetic valve actuator; piezoelectric valve actuator; camshaft position pin actuator

- Data Communications

- Control Unit Communication: Typically Control Area Network (CAN) Bus System

- Manufacturers

- BorgWarner, Bosch, Delphi, Denso, FEV, Hitachi, Sturman Industries, Valeo

- For More Information

- [1] How Camshafts Work, Karim Nice, Howstuffworks.com, Dec. 13, 2000.

- [2] Camshafts Part III: Variable Valve Timing, Abdul Rehman, StreetRacersOnline.com, Aug. 27, 2004.

- [3] Camless Engines, Autospeed.com.

- [4] Variable Valve Timing, Wikipedia.

- [5] e-Valve System, Valeo brochure describing electromagnetic valve control. [pdf]

- [6] Camless Engine Capstone Project WVU, YouTube, May 4, 2010.

- [7] K-Series iVTEC VTC Cam Phasing System - In Depth, YouTube, August 2010.

- [8] BorgWarner Morse TEC Cam Torque Actuated (CTA) Variable Camshaft Timing Technology, YouTube, July 24,2009.

- [9] Cam-Torque Actuated Variable Valve Timing System, M. Austin, Car and Driver, August 2010.

- [10] Variable Valve Timing.flv, YouTube, Jan. 19, 2011.

-

|