CarbonDEP refers to the use of carbon microelectrodes to induce a Dielectrophoresis (DEP) form on bioparticles of interest.

Heat treatment of an organic precursor in an inert atmosphere, a process generally known as pyrolysis, yields a carbonaceous material that is electrically conductive, featuring an electrical resistivity of 1 X 10-4 Ω/m when pyrolysis is performed at temperatures around 900 °C in an atmosphere such as nitrogen. Such resistivity is similar to that of indium tin oxide but four orders of magnitude more than Cu. Nonetheless, it still allows for the use of low-voltage sources, <20 Vpp, to implement a practical Dielectrophoresis (DEP) force when the gaps between electrodes are in the order of tens of micrometers. A well-known advantage of glass-like carbon over other electrode materials such as Au or Pt is that it is more electrochemically stable. This allows for a stronger DEP force when using carbon electrodes since a higher voltage can be applied without electrolyzing the sample. In terms of materials, a polymer precursor for glass-like carbon work is significantly less expensive that noble metals.

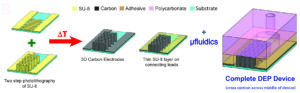

The complete process to fabricate carbonDEP devices is illustrated in figure 1 and is detailed elsewhere. The important steps are 1) photolithography of SU-8, 2) carbonization and 3) coupling of the carbon electrodes in the microfluidics networks. SU-8 photolithography is implemented in two steps: a) fabrication of planar interdigitated fingers that will become carbon connection leads to the base of the 3D carbon electrodes and b) fabrication of SU-8 geometries that will become the 3D carbon electrodes. Once a 3D SU-8 topography is fabricated, it is introduced in a tube furnace and heat treated under an inert atmosphere, usually nitrogen. Near-isometric shrinkage occurs during pyrolysis and is especially important to DEP because the gaps between carbon electrodes are wider than those fabricated in SU-8. In an optional step, a thin SU-8 layer of around 2 μm can be patterned around the carbon electrodes to electrically insulate the connection leads and to planarize the surface around the base of the electrodes. The fabrication sequence presented often results in dense arrays of carbon electrodes with height ~100 um which effectively increase the cell capacity/square centimeter of carbonDEP devices. Furthermore, the process is highly reproducible given the use of commercial precursors like SU-8 and the use of photolithography for patterning.

Further references

Y. Yildizhan, N. Erdem, M. Islam, R. Martinez-Duarte and M. Elitas, “Dielectrophoretic Separation of Live and Dead Monocytes using 3D Carbon-electrodes“, Sensors, 17 (11), 2691 (2017). PDF

R. Martinez-Duarte “Fabrication Challenges and Perspectives on the use of Carbon-electrode Dielectrophoresis in Sample Preparation” IET Nanobiotechnology (2016). Invited Critical Review. Accepted Manuscript

Islam, R. Natu, M. F. Larraga-Martinez and R. Martinez-Duarte “Enrichment of diluted cell population from large sample volumes using 3D Carbon-electrode Dielectrophoresis” Biomicrofluidics, 10, 033107 (2016). Accepted Manuscript

M. Islam, R. Natu and R. Martinez-Duarte, “A study on the limits and advantages of using desktop cutter plotter to fabricate microfluidic networks” Microfluidics and Nanofluidics, 19, (4), 973-985 (2015). Accepted Manuscript

M. Elitas, R. Martinez-Duarte, N. Dhar, J. McKinney and P. Renaud, “Dielectrophoresis-based purification of antibiotic-treated bacterial subpopulations”. Lab on a Chip, 14, (11) 1850-1857 (2014). Video. Accepted Manuscript

R. Martinez-Duarte, “Carbon-electrode Dielectrophoresis for Bioparticle Manipulation”. ECS Transactions, 61, (7), 11-22 (2014). Accepted Manuscript

R. Martinez-Duarte “Micromanufacturing Technologies in Dielectrophoresis Applications”, Application focus of the AES Electrophoresis Society, September, 2013.

R. Martinez-Duarte, F. Camacho-Alanis, P. Renaud and A. Ros, “Dielectrophoresis of lambda-DNA using 3D carbon electrodes” Electrophoresis, 34, 1113-1122 (2013).

M.C. Jaramillo, R. Martinez-Duarte, M. Hüttener, P. Renaud, E. Torrents and A. Juarez, “Increasing PCR sensitivity by removal of Polymerase inhibitors in natural samples using Dielectrophoresis”. Biosensors and Bioelectronics, 43, 297-303 (2013).

G. Mernier, R. Martinez-Duarte, R. Lehal, F. Radtke and P. Renaud, “Very High throughput electrical cell lysis and extraction of intracellular compounds using 3D carbon electrodes in lab-on-a-chip devices” Micromachines, 3, 574-581 (2012). Open Access.

R. Martinez-Duarte and M. Madou, “3D Carbon-electrode Dielectrophoresis”, Application focus of the AES Electrophoresis Society, October, 2011. www.aesociety.org/areas/dielectrophoresis.php

R. Martinez-Duarte, P. Renaud and M. J. Madou, “A novel approach to dielectrophoresis using carbon electrodes” Electrophoresis, 32, 2385-2392 (2011). Accepted Manuscript

R. Martinez-Duarte, R. Gorkin, K. Abi-Samra, M. Madou, “The integration of 3D Carbon-electrode Dielectrophoresis on a CD-like Centrifugal Microfluidic Platform” Lab-on-a-chip, 10, 8, 1030-1043 (2010). Accepted Manuscript

M. C. Jaramillo, E. Torrents, R. Martinez-Duarte, M. Madou and A. Juarez, “On-line separation of bacterial cells by carbon-electrode dielectrophoresis” Electrophoresis, 31, 2921-2928 (2010).

R. Martinez-Duarte, G. Turon Teixidor, P. Mukherjee, Q. Kang and M. J. Madou,

“Perspectives of Micro and Nanofabrication of Carbon for Electrochemical and Microfluidic Applications” in Microfluidics and Microfabrication edited by S. Chakraborty, Springer, 181-263 (2009). PDF

R. Martinez-Duarte, S. Cito, E. Collado-Arredondo, S. O. Martinez and M. Madou, “Fluido-dynamic and Electromagnetic Characterization of 3D Carbon Dielectrophoresis with Finite Element Analysis” Sensors & Transducers Journal, 3, 25-36 (2008). Open Access. PDF

R. Martinez-Duarte “Label-free Cell sorting using Carbon-electrode Dielectrophoresis and Centrifugal Microfluidics“, Mechanical and Aerospace Engineering, University of California, Irvine (2010). PDF