Dual Clutch Control

by Laura Todd, Clemson Electrical Engineering Student

- Basic Description

-

Dual clutch control, while common in race cars, is a fairly new technology for production automobiles and first appeared in the 2003 model year. Working together, electronic transmission control, sensors, and actuators make up dual clutch control. A dual clutch transmission (DCT) is considered middle ground between a manual and an automatic transmission; using positive aspects from both. Several other names are used to describe this transmission including semi-automatic, clutchless manual transmission, and automated manual transmission.

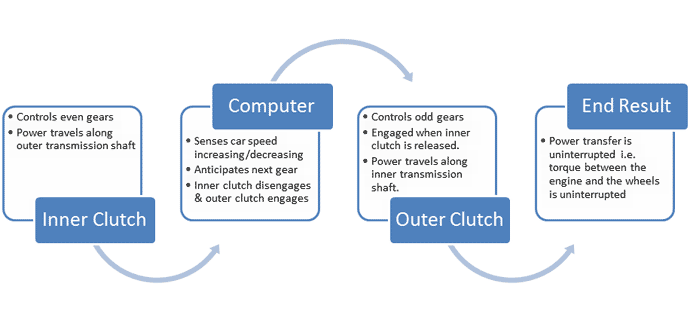

A DCT is essentially the integration of two manual transmission systems with computer interfacing. It utilizes two clutches: one clutch for even gears (inner clutch) and one clutch for odd gears (outer clutch). Using a computer interface, the car is able to switch from one gear to the second gear and consequently, one clutch to another when necessary. To communicate, CAN bus and FlexRay interfacing is used. The system is operated by either a console-mounted shifter or paddles on the steering wheel.

An important distinction between a manual transmission and a semi-automatic is the interrupt of power to the transmission. By implementing a design with two clutches, the system never has to disrupt the power flowing to the transmission; eliminating the jerky movements sometimes present in manual transmissions. Additionally, the continuous flow of power offered by the DCT is more fuel efficient than a fully automatic transmission because no torque converter is required.

Today, there are two main types of dual clutch options available: dry clutch and wet clutch. Wet clutch technology refers to components that are running in oil. The necessary thermal capacity is provided by cooling fluid and hydraulic pressure actuates the clutches. Dry clutch technology implements electric motors to actuate the dual clutch.

The Schaeffler Group is credited with designing the first dry clutch technology and Renault improved on the technology in 2010 by using electromechanical actuators to improve fuel economy. Their model is referred to as Efficient Dual Clutch (EDC).

- Sensors

- Sensors used to determine engine speed, road speed, accelerator position, and driving mode. This could include: throttle valve position sensor, pedal position sensor, wheel speed sensor, torque sensor, crankshaft angle sensor, or engine speed sensor.

- Actuators

- Dry clutch technology relies on electric motors, while wet clutch technology relies on hydraulic pressure.

- Data Communications

- Typically CAN but FlexRay is also used.

- Manufacturers

- BorgWarner, Continental, Delphi, Fiat Powertrain, Getrag, Orelikon Graziano, Ricardo, Schaeffler, ZF

- For More Information

- [1] Dual Clutch Transmission, Wikipedia.

- [2] How Dual-Clutch Transmissions Work, William Harris, Howstuffworks.com, 2008.

- [3] ZF 7DT Dual Clutch Transmission, YouTube, Feb. 21, 2010.

- [4] Porsche PDK, YouTube, Mar. 26, 2011.

|