Transmission Control

- Basic Description

-

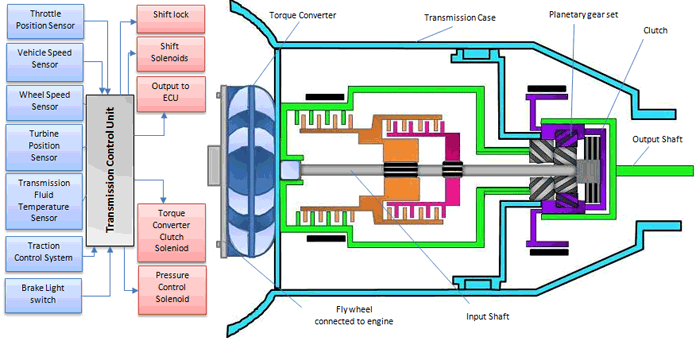

The Transmission Control Module (TCM) controls modern automotive transmissions based on

input from various sensors as well as data provided by

engine control module (ECM). It processes this input to calculate how and when to shift gears in the transmission and generates

the signals that drive actuators to accomplish this shifting. The software in the TCM is

designed to optimize vehicle performance, shift quality and fuel efficiency.

Electronic sensors monitor the gear position selection, vehicle speed, throttle position

and a number of other parameters. Based on this information, the control module adjusts the current supplied to solenoids

in the transmission that control the position of various valves and gears.

The gear position selector switch communicates to the TCM which gear has been selected by the operator. The crankshaft position sensor provides information to the TCM to determine the existing rotational speed of the engine. This information helps the TCM determine when to change gears. The throttle position sensor tells the TCM how far the throttle is open which indirectly indicates the engine load. This input is used to determine the best time to change a gear. The turbine speed sensor determines the speed of the torque converter. The TCM uses this information to find the slippage across the torque converter,

which helps it decide when to activate the torque converter lock-up clutch. The torque converter lock-up clutch increases the efficiency of the transmission by eliminating the hydraulic and pumping losses associated with the torque converter when traveling at steady high speeds. The transmission fluid temperature sensor is used to ensure that the automatic transmission fluid is at the correct temperature. If the automatic transmission fluid is hot, then the transmission is downshifted.

The brake pedal position sensor helps to ensure that the driver has applied the brake before shifting into park or reverse. The TCM may also downshift the transmission if the vehicle is going downhill in order to utilize the compression braking of the engine.

Inputs from the traction control system instruct the transmission to downshift when one or more tires are losing traction.

Thanks to electronic transmission controls, modern automatic transmissions are much more

fuel efficient than their purely mechanical/hydraulic predecessors. They also exhibit smoother shifting,

reduced engine emissions, greater reliability and improved vehicle handling.

On some vehicles, the functions of the TCM and ECM are combined in a single module called the

Powertrain Control Module or PCM.

- Sensors

- Crankshaft position sensor, wheel speed sensor, throttle position sensor, gear position sensor, transmission

fluid temperature sensor, engine coolant temperature sensor, turbine speed sensor, brake light switch

- Actuators

- Solenoid Actuated Valves: Powered by relays at TCM.

- Pressure Regulating Solenoids: Force Motor Solenoids, Variable Bleed Solenoids.

- Shift Solenoids: Electrical solenoids which are activated to change gears.

- Torque Converter Clutch Solenoids: Lock up stock style, Non lock up style.

- Data Communications

- Control Unit Communication: Typically Controller Area Network (CAN) Bus System

- Manufacturers

- ACDelco,

Allison Transmission, Baumann, BorgWarner, Bosch, Continental, Delphi, Hitachi, Magneti Marelli, PCS, TCI, Tremec, Wabco, ZF

- For More Information

- [1] 1966 GTO: TCI Transmission Controller V8TV, YouTube, Mar. 2009.

- [2]

Transmission Control Unit, Wikipedia.

- [3]

Torque Converter, YouTube, Apr. 10, 2008.

- [4]

Suzuki Automotive Explains "CVT" or Continuously Variable Transmission, YouTube, Aug. 10, 2011.

- [5] How Torque Converters Work! (Animation), YouTube, Jan. 10, 2014.

- [6] How Automatic Transmissions Work! (Animation), YouTube, Jan. 24, 2014.

- [7] DSG Transmission - Explained, YouTube, Jan. 21, 2015.

|