Electronic Valve Timing Control

- Basic Description

-

The valves in an internal combustion engine open and close to allow both the fuel-air mixture to enter the cylinder prior to combustion and to allow the exhaust gases to exit the cylinder after combustion. In most engines, the valves are opened by lobes connected to the camshaft. The shape of these lobes determines the lift, timing and duration of each valve opening. In an engine with fixed valve timing, the timing is not optimal for all engine speeds. For example, if a camshaft is designed to operate the valves for optimal timing at low RPMs, then at higher RPMs each cylinder would be deprived of sufficient fuel and air mixture, limiting the engine power output. Conversely, if optimized for high RPMs, the vehicle would experience rough idling at low RPMs. There are several methods for changing the valve timing such as using multiple camshafts or eliminating the camshaft altogether, altering the timing of the intake camshaft, and controlling the valve timing with electronic, hydraulic or pneumatic actuators. Variable valve timing can significantly increase both the power and fuel efficiency of an internal combustion engine.

Electronic valve control (EVC) systems attempt to optimize the valve timing over the entire range of possible engine speeds. Most existing systems manipulate the valve timing using a computer controlled actuator attached to the camshaft. Sometimes two camshafts are used, one to control the intake valves and the other to control the exhaust valves. The camshaft may have two sets of lobes where one set is designed for low and the other for high RPMs. As the camshaft rotates, the lobes push open the spring-loaded valves, which are then closed by the force of springs. An electronic control unit (ECU) selects which set of lobes to use based on the engine speed. Another approach to variable valve timing employs a cam phasing mechanism to monitor and adjust the rotation of the camshaft relative to the rotation of the crankshaft.

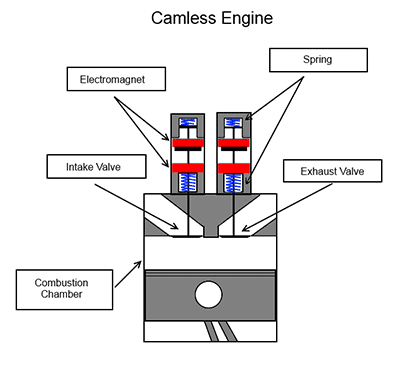

There are other mechanical/electrical methods that come one step closer to eliminating the camshaft altogether. Three of these methods are electro-pneumatic valves (EPV), electro-hydraulic valves (EHV), and electromagnetic valves (EMV). EPV and EHV use electric solenoids to control the flow of compressed air or hydraulic fluid to the valves at the appropriate time. Existing EPV and EHV systems generally eliminate the spring mechanism but still employ the cam. EPV systems are commonly found on Formula One engines and EHV systems are being employed by the engines on BMW vehicles. Electromagnetic valves control the valve opening directly with a solenoid, eliminating camshafts and many other related components such as lifters and timing chains. Engines of this design are currently undergoing development and have not made it past the prototype stage. They have yet to come to market because of the expense as well as the power required to operate the actuator. EMV systems allow for nearly infinite combinations of duration, lift, and phase of both the intake and exhaust valves. This allows greatly improved control over engine performance characteristics facilitating reduced emissions, increased low-end torque and increased peak horsepower.

- Sensors

- Crankshaft Position Sensor, Throttle Position Sensor, Fluid Pressure Sensor

- Actuators

- Hydraulic, pneumatic or electromagnetic valve actuator, piezoelectric valve actuator, camshaft position pin actuator

- Data Communications

- Control Unit Communication: Typically Control Area Network (CAN) Bus System

- Manufacturers

- BMW, BorgWarner, Chevrolet, Delphi,

Denso, FEV, Hitachi, Honda, Jacobs Vehicle Systems, LaunchPoint Technologies, Mechadyne, Mitsubishi, Sturman Industries, Subaru

- For More Information

- [1] Variable Valve Timing, Wikipedia.

- [2] How Camshafts Work, Variable Valve Timing, Karim Nice, Howstuffworks.com, Dec. 13, 2000.

- [3] BorgWarner Morse TEC Cam Torque Actuated (CTA) Variable Camshaft Timing Technology, YouTube, July 24, 2009.

- [4] Camless Engine Capstone Project WVU, YouTube, May 4, 2010.

- [5] K-Series iVTEC VTC Cam Phasing System - In Depth, YouTube, Aug. 10, 2010.

- [6] The Benefits of Variable Valve Timing, CarsDirect, Feb. 17, 2012.

- [7] The Future of the Internal Combustion Engine - /Inside Koenigsegg, YouTube, Feb. 19, 2013.

- [8] Electromechanical Valve Actuator for Variable Valve Timing, YouTube, Mar. 25, 2013.

- [9] How Variable Valve Timing Works, David Tracy, Jalopnik, June 3, 2013.

- [10] The Camless Engine, John Coxon, High Power Media, Aug. 20, 2013.

- [11] Car Tech 101: Variable Valve Timing Explained, YouTube, Apr. 28, 2014.

- [12] Camless Engines, Dusko Mackoski, Autospeed.com, Oct. 7, 2014.

|