| |

In the S.M.A.R.T. Lab we are interested in using Sensors, Materials, and Analytics together for the translation of research to clinical and industrial applications for the betterment of society. You will find that our research is interdisciplinary by nature, and we actively seek to build an interdisciplinary research team to meet these needs. Particularly we are interested in those who are excited to work well with those that think and learn differently than themselves. Diversity in research expertise and background is one of the strengths of our group! Please see our research projects below and contact us with any questions or interests you may have.

|

| |

Smart Wound Dressings for Chronic Wounds

Chronic wounds, resulting from injuries such as burns, diabetic ulcers, or non-healing surgical sites, present significant challenges for patients, clinicians, and researchers across the globe. These wounds are characterized by a frustrated inflammatory response and high likelihood of infection. The possibility of infection is especially troubling because this may lead to tissue death, amputation, or systemic infection (sepsis leading to death). The S.M.A.R.T. Lab is taking a theranostic approach to addressing the chronic wound healing problem through development of smart wound dressings for diagnosis and treatment of these wounds.

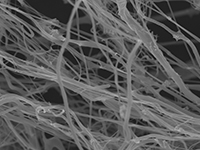

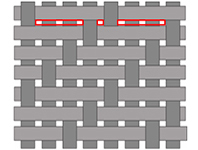

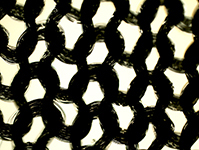

Treatment of Chronic Wounds through Medical Textiles

Important factors in the management of chronic wounds include:

1. Infection Management

2. Moisture Regulation

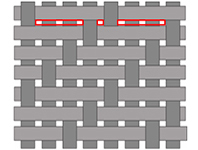

3. Ingrowth of Granulation Tissue

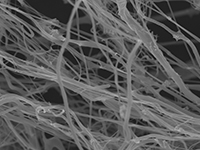

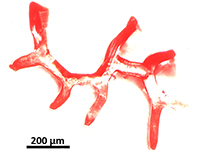

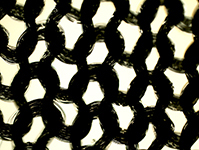

Our lab approaches these three areas through fabricating biomaterial-based wound dressings based on textile technology. We produce micro and nano-scale monofilaments and yarns through an array of polymer spinning techniques (i.e. solution blow spinning, electrospinning, melt spinning) and arrange these fibers into wound dressings via knitting or weaving. Arranging fibers using these textile methods offers the unique opportunity to control mechanical properties, geometry, and surface characteristics. Each of these variables can be modulated to effect wound healing in one or more of the areas mentioned above.

Biosensing the Wound Environment

Diagnosing chronic wounds is currently a highly subjective process in which infection likelihood, wound severity, and prognosis for healing are generally determined through visible inspection and clinician experience. Our aim is to use conductive nanofiber-based biosensors to characterize the state of chronic wounds in real time. In this way, clinicians will be equipped with a quantitative measure of wound state, enabling a consistency of treatment strategies across all clinical practice.

Physiological Sensing for Data-driven Detection of Empathy in Psychotherapy Sessions

Many concepts considered essential to successful psychotherapy treatments, such as trust, empathy, or conflict resolution are seen as “soft-skills” that are difficult to quantify or teach. These psychotherapy process variables contribute to the “black box” of therapy and are directly related to therapeutic alliance, the verbal or nonverbal agreement between therapist and patient that each will work together for the success of the treatment. We are implementing a new approach focused on physiological sensing using wearable technology to understand the physiological patterns in heart rate, heart rate variability, and galvanic skin response related to these variables. Our ability to autonomously detect these variables via machine learning will be an important step in quantification of these skills for training and feedback, thereby improving the quality of therapy for many future patients.

|

|

| |

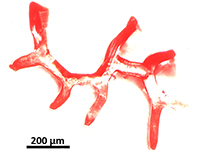

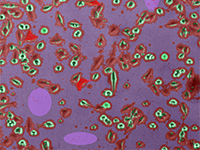

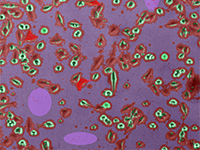

Multivariate Analysis of CHO Cell Culture for Biomanufacturing Optimization

The optimization of manufacturing of cell-based drugs is currently an important area of research for the U.S. as we attempt to reduce the cost of prescription medicines, streamline the development process for new drugs, and increase the efficacy of these medicines. Chinese Hamster Ovary (CHO) cells have been an important component of biomanufacturing for the last 30 years. However, due to genomic variation, complex culture requirements and processes, and challenges with research at industrially relevant scales, research in the optimization of these cells as producers of therapeutic or diagnostic proteins has been mainly accomplished through trial-and-error at the industry scale. We are focused on applying machine learning techniques for multivariate analysis of CHO cell cultures in bioreactors. Our goal is to relate bioreactor process control variables, CHO genomic information, and phenotypic outcomes for productivity.

|

| |

|