Smart (Controllable) Blending and Novel Morphologies Produced by Chaotic

Advection

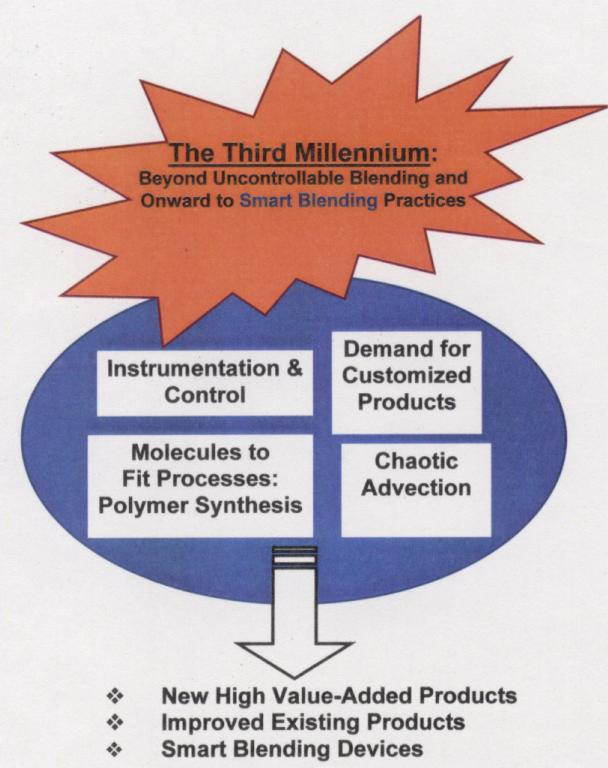

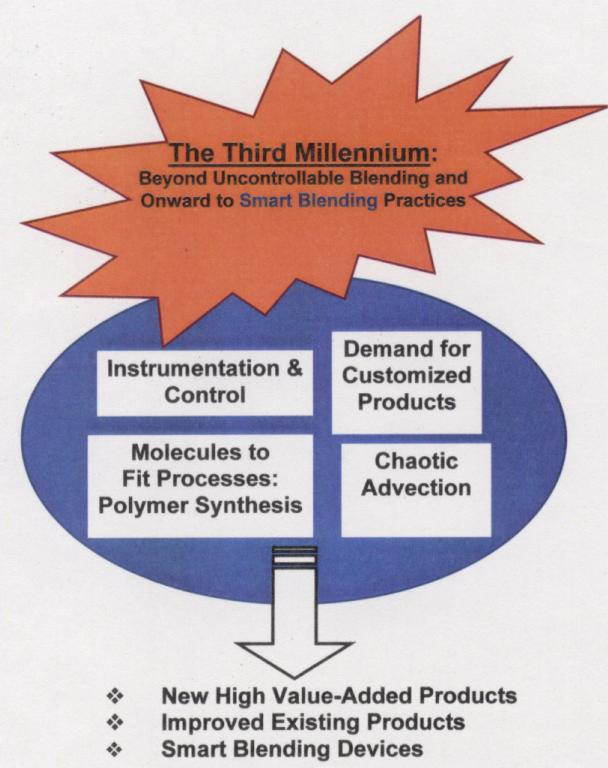

In the Third Millennium, we need to move beyond uncontrollable

blending when making plastics, extrusions of various types, and certain

high-value added fiber and film products. Currently, polymer blends are

formed with little means to obtain desired shapes among components (e.g.,

of melts A and B) during mixing steps. Blend morphology is for the most

part an uncontollable outcome so that extrusions or injection-molded parts

are rarely optimized with regard to structure-property relations.

Most often, composition strongly governs morphology. It is preferable to

promote and retain specific shapes over wide ranges in composition  within polymer melts to effect desired properties. Fiber glass,

for example, would be worthless if the glass fibers were chopped into

bits and then added to the matrix component! What if we could blend two

or more polymers and deliberately convert them in doing so to multi-layers,

platelets, fibers, or other shapes? We are doing this in the LAPM&T

to create plastic products with enhanced properties and also develop processes

that are controllable. Multilayer films have been produced that

consist of thousands of individual layers with layer thicknesses in some

cases below 200 nanometers. Fibers have also been extruded that contain

thousands of internal fibers. The multi-layers and internal fibers

were formed directly and controllably in multicomponent melts subjected

to chaotic advection (also sometimes referred to as chaotic mixing) conditions.

Thermoplastic composites have also been produced in this manner with particulate

and fiber additives to yield electrically conducting and fiber-reinforced

materials. In these materials, percolating structures were in essence constructed

in lieu of being the outcome of random associations among additives.

within polymer melts to effect desired properties. Fiber glass,

for example, would be worthless if the glass fibers were chopped into

bits and then added to the matrix component! What if we could blend two

or more polymers and deliberately convert them in doing so to multi-layers,

platelets, fibers, or other shapes? We are doing this in the LAPM&T

to create plastic products with enhanced properties and also develop processes

that are controllable. Multilayer films have been produced that

consist of thousands of individual layers with layer thicknesses in some

cases below 200 nanometers. Fibers have also been extruded that contain

thousands of internal fibers. The multi-layers and internal fibers

were formed directly and controllably in multicomponent melts subjected

to chaotic advection (also sometimes referred to as chaotic mixing) conditions.

Thermoplastic composites have also been produced in this manner with particulate

and fiber additives to yield electrically conducting and fiber-reinforced

materials. In these materials, percolating structures were in essence constructed

in lieu of being the outcome of random associations among additives.

Examples are shown below

of some structured polymeric materials and computer-generated results.

In the upper left, a very highly multilayered film morphology is shown.

The film layers were formed from polymer melt streams in a continuous chaotic

advection blender, also known as a smart blender or chaotic blender, and

extruded as filaments. Similar layered structures have also been extruded

in film form. In the color image, conditions to instill 3D chaotic advection

throughout a cavity intended for polymer processing were ascertained using

pigmented fluids. Results were cross-checked with computational fluid

mechanics models. In the right upper figure, a computational simulation

is shown of a circular blob converted to a folded film (shown in cross-section).

Subsequent modeling and experiments showed that the films multiplied by

repeated stretching and folding and fragmented in some cases to yield abundant

fibers. For example, very many internal fibers are shown within an extruded

filament in the lower left figure. In the lower center figure,

percolating networks were constructed among carbon black particles to render

polystyrene electically conducting. Chaotic advection organized the

particle additives into long branched filaments such that interconnections

were promoted. In the lower right picture that was generated computationally,

a droplet acted as a type of internal stirrer and improved mixing uniformity

by collapsing an island where mixing conditions were poor. While our studies

are focused on the development of new polymer processes and materials,

fundamentals of general importance to blending and chaotic mixing such

as those related to the effects of interfaces among melt components are

also addressed.

The demand for products with particular characteristics

increases on a daily basis. Manufacturers must meet the specific needs

of customers which may change monthly. Our studies in chaotic advection

have demonstrated that shapes among components can be controllably evolved.

Often, for example, large blobs are converted to sheets which refine

to multi-layers. Morphological transitions among the layers can lead to

many other shapes-many of which may be useful. Notably, many of these morphologies

are not observed in common blending equipment since they may only appear

locally within devices and as short-lived transitional structures.

In our processes, however, desired shapes can be constructed in situ and

delivered to dies for extrusion. Controllable blending methods can make

effective use of molecules that are synthesized to have particular processing

characteristics and properties. And of course, with controllable

blending technologies, manufacturers can optimize products on-line by also

using instrumentation and control technologies. We feel that the time has

come to move beyond uncontrollable blending and onward to Smart Blending

practices.

[HOME] [Mission]

[Research] [Position]

[Publication] [Gallery]

within polymer melts to effect desired properties. Fiber glass,

for example, would be worthless if the glass fibers were chopped into

bits and then added to the matrix component! What if we could blend two

or more polymers and deliberately convert them in doing so to multi-layers,

platelets, fibers, or other shapes? We are doing this in the LAPM&T

to create plastic products with enhanced properties and also develop processes

that are controllable. Multilayer films have been produced that

consist of thousands of individual layers with layer thicknesses in some

cases below 200 nanometers. Fibers have also been extruded that contain

thousands of internal fibers. The multi-layers and internal fibers

were formed directly and controllably in multicomponent melts subjected

to chaotic advection (also sometimes referred to as chaotic mixing) conditions.

Thermoplastic composites have also been produced in this manner with particulate

and fiber additives to yield electrically conducting and fiber-reinforced

materials. In these materials, percolating structures were in essence constructed

in lieu of being the outcome of random associations among additives.

within polymer melts to effect desired properties. Fiber glass,

for example, would be worthless if the glass fibers were chopped into

bits and then added to the matrix component! What if we could blend two

or more polymers and deliberately convert them in doing so to multi-layers,

platelets, fibers, or other shapes? We are doing this in the LAPM&T

to create plastic products with enhanced properties and also develop processes

that are controllable. Multilayer films have been produced that

consist of thousands of individual layers with layer thicknesses in some

cases below 200 nanometers. Fibers have also been extruded that contain

thousands of internal fibers. The multi-layers and internal fibers

were formed directly and controllably in multicomponent melts subjected

to chaotic advection (also sometimes referred to as chaotic mixing) conditions.

Thermoplastic composites have also been produced in this manner with particulate

and fiber additives to yield electrically conducting and fiber-reinforced

materials. In these materials, percolating structures were in essence constructed

in lieu of being the outcome of random associations among additives.