|

|

College of Engineering & Science |

|

|

|

College of Engineering & Science |

|

Current Highlights

|

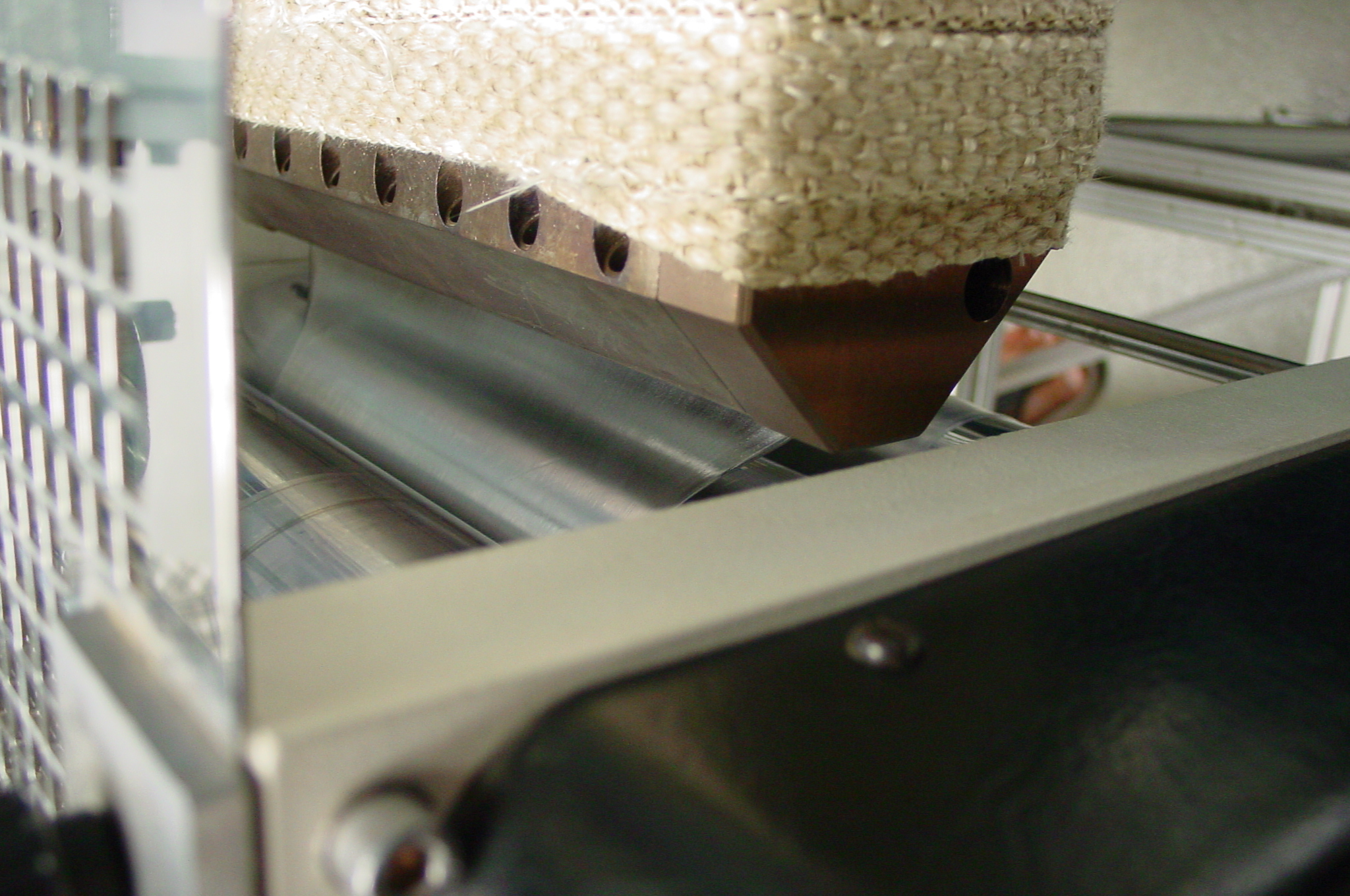

Smart blender in action!...A smart blender can be configured with a variety of dies to give extruded plastics with many types of morphologies or structural arrangements among solid additives in a desired net shape (i.e., film, pipe, tubing, sheet). In the photograph, a prototype smart blender is fitted with a film die where film is shown contacting a chill roll prior to winding. The film consists of two common thermoplastics arranged to impart property enhancement via morphology optimization. Structure-property optimization can be readily done since morphology can be controllably developed with smart blenders. For information on smart blending concepts, please see the tutorial. |

|

Controllable formation of submicron multiple layers: A new chaotic advection-based process has been developed where plastic extrusions of various forms (e.g, film, pipe, sheet, etc.) can be produced with a variety of blend morphologies in continuous lengths. Essentially, morphology is selectable on-line by control of chaotic advection and other parameters such that no equipment modifications are required. In the micrograph, an example is shown of a novel blend that contains thousands of internal sub-micron layers (Zumbrunnen, D. A. and Inamdar, S., 'Novel Sub-Micron Highly Multi-layered Films Formed by Continuous Flow Chaotic Mixing,' Chemical Engineering Science, Vol. 56, pp. 3893-3897, 2001). The thicknesses and number of layers are selectable via control features in smart blending devices. Fibrous, interpenetrating, platelet, percolating, and droplet morphologies are examples of other blend morphologies that have been formed. Various morphologies are obtained via sequential morphology transitions beginning with the layered morphology. Some morphology examples are given at the top of this page. (TOP) For more recent examples, please see our publications. |

|

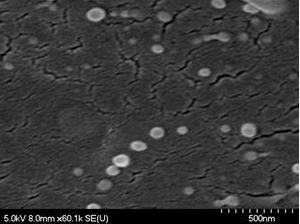

Formation of very

small droplets and other nano-scale shapes

in polymer blends and viscous liquids:

A frequent goal is to produce very

small droplets. Intensive mixing is commonly

used in order to disperse and break up a viscous

minor component. However, with smart blending

methods, the minor component is converted initially

to very thin, numerous layers in the melt by chaotic

advection. The layers break up to give droplets such

as the 50 nanometer droplets shown in the micrograph

to the left. Droplet size is correlated to the parent

layer thickness so extremely small diameter droplets

can be formed in polymer combinations where very

thin layers can be created. Manufacturing processes that

make use of this approach can have much reduced energy expenditures

in comparison to current processing methods, such as

compounding in a twin screw extruder. Also, a low shear

condition allows use of melts that are prone to degradation.

Methods can also be used to form other nano-scale structures

in melts among solid additives or melt components for retention

in extrusions of desired forms (e.g., sheet, film, pipe).

For more information, see: D. A.Zumbrunnen, S. Inamdar,

O. Kwon, and P. Verma, "Chaotic Advection as a Means

to Develop Nanoscale Structures in Viscous Melts,"

Nano Letters, Vol. 2, pp. 1143-1148,

2002. |

|

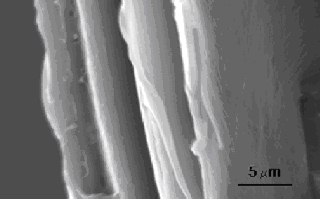

Low permeation (high

barrier) plastics: Kwon, O. and

Zumbrunnen, D. A., "Production of Barrier Films

by Chaotic Mixing of Plastics,"

Polymer Engineering

& Science, Vol. 43, pp. 1443-1459, 2003.

Abstract:

Recent studies have demonstrated that

highly multilayered blend morphologies can

be formed by chaotic mixing and captured

within extrusions of various forms. The

number and thickness of internal layers prior

to layer breakup and the extent of breakup are

controllable via specification of process variables.

A variety of derivative morphologies can thereby

be obtained. Although methods can be applicable to

other blends, the relation of oxygen permeability

to various morphologies was specifically investigated

in this study for extruded films without stretching

consisting of ethylene vinyl alcohol copolymer, low density

polyethylene and maleic anhydride modified polyethylene

as a compatibilizing agent. Optimal barrier properties

were obtained in a novel single phase continuous and

mechanically interlocked morphology that was an outcome

of stretching and folding characterizing chaotic mixing.

Barrier properties were similar to those obtainable

in co-extruded films due the presence of abundant platelets

across the film thickness and crystallinity increases

caused by barrier phase refinement. (In the micrograph, an extruded film was immersed

in liquid nitrogen and fractured to reveal thin platelets

that were formed. Entire

films contained numerous platelets and other high surface

area shapes such as ribbons that were volumetrically

distributed throughout the film thickness. Because

finer internal barrier structures can be formed

in them, the potential is to produce barrier films that

exceed the performance of co-extruded films.)

|