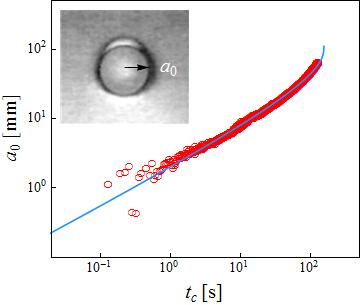

Manipulation of liquids on the micro-scale is of fundamental interest in industrial applications, which often require the interaction between competing physical effects to operate. Thin film flows are often viscous-dominated because of the small aspect ratio. For example, a fluid hole on a perfectly wetting substrate will collapse at a rate characterized by the balance between dynamic capillary wetting forces and viscous stresses (Figure (right) below).

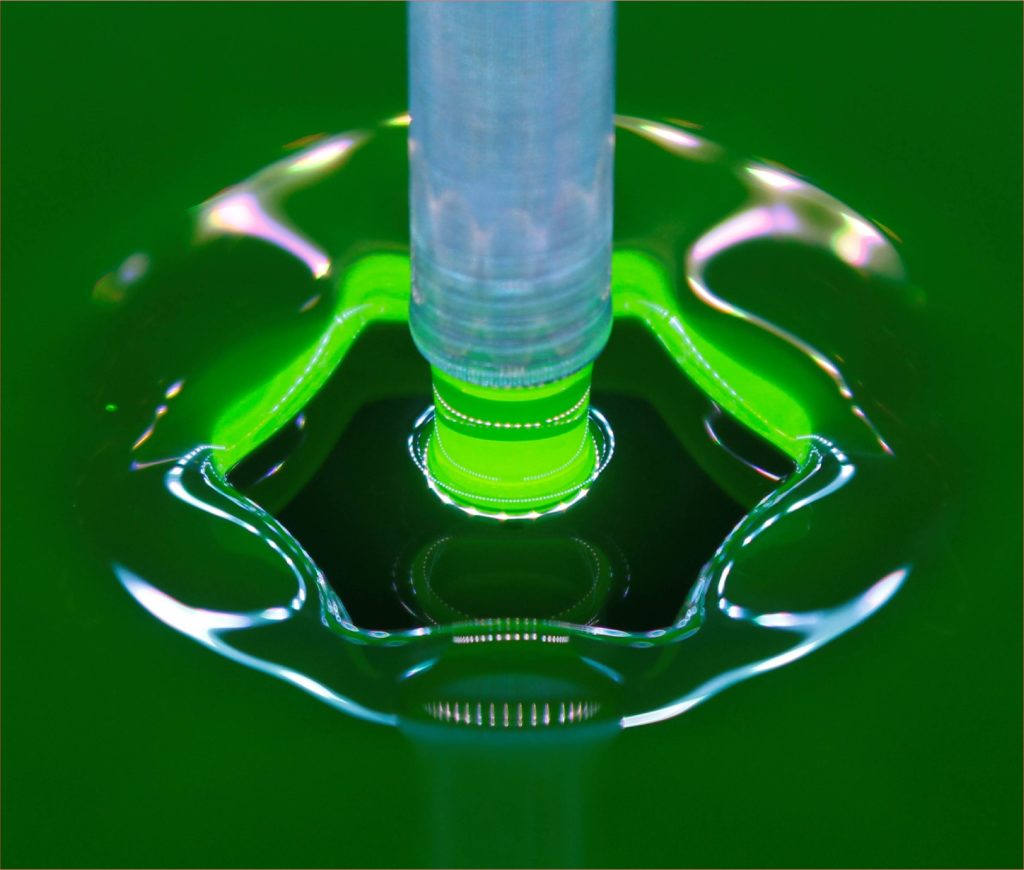

Polygonal hydraulic jumps

The circular hydraulic jump seen in your kitchen sink takes on a similar geometry to the fluid hole, but with the addition of the fluid inertia associated with base flow. For certain combinations of experimental parameters, the circular jump loses stability in favor of a polygonal shape (Figure (left) below) and other more complex shapes. Somewhat surprisingly, the geometry of the polygonal jump appears to be universal.

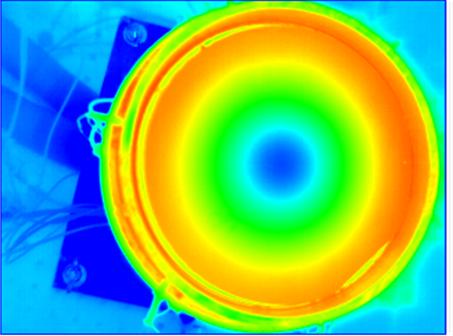

Marangoni flows

Surface stresses are particularly useful to drive internal flows in thin films, because of large surface-to-volume ratios. Surface tension gradients caused by temperature or surfactant concentration gradients can induce `Marangoni-driven’ flows from regions of high surface tension to low surface tension. For example, when a droplet is placed on a differentially-heated substrates (Figure (right)), this can generate a complex temperature profile within the droplet. Here there is a competition between surface chemistry (wetting) and thermocapillary flows induced by the thermal gradient which gives rise to bistability (i.e. two equivalent equilibrium droplet configurations) in certain regions of parameter space.

Marangoni flows are particularly important to drive flows in low-gravity environments, as they are an alternative to traditional gravity-driven flows. For example, buoyancy-driven convection (Rayleigh-Benard instability) is suppressed in low-g in favor of thermocapillary-driven convection (Marangoni-Benard instability) and an understanding of such flows is often mission critical and needed to develop new low-g technologies.