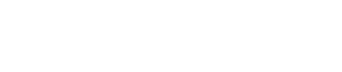

Ultrasonic-assisted soldering (UAS) is a manufacturing process for joining dissimilar materials without the use of environmentally-harmful flux, which is traditionally used to enhance wetting of the solder materials. Ultrasonic energy applied to the molten solder pool causes the rapid formation and collapse of cavitation microbubbles, which creates localized areas of extremely high temperature and pressure that remove the surface oxide layer (`scrubbing action’) of the substrate and improves solder wettability and adhesion. This multiphysics process involves solidification (phase change), heat transfer, acoustics, fluid mechanics, and surface science (wetting and adhesion), and is schematically illustrated in the Figure below.

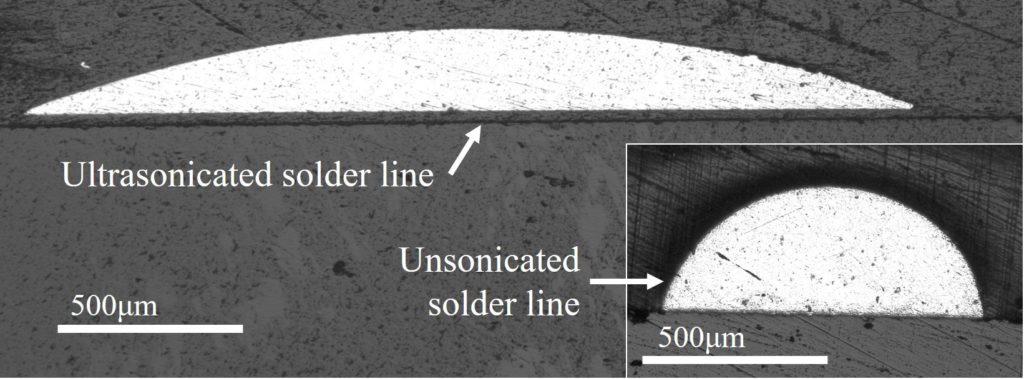

Our research team has recently developed an automated ultrasonic soldering platform, adapted from a commercially available 3D printer, that allows for precise control of a large number of process parameters. Current studies are focused on quantifying the wetting properties and mechanical strength of solder-to-ceramic joints.