Motivation

Extreme temperatures impacts battery usage and powertrain performance

Intelligent and predictive thermal and energy management is key to unlock potentials of hybrid powertrain and assess different technologies

Goal

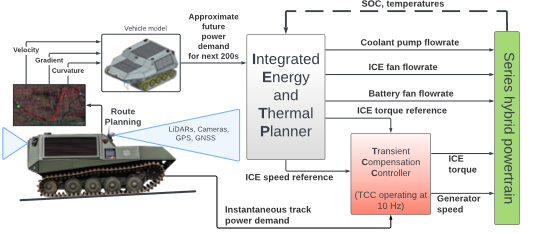

Develop control techniques to improve thermal management and efficiency of hybrid propulsion systems in autonomous off-road vehicles

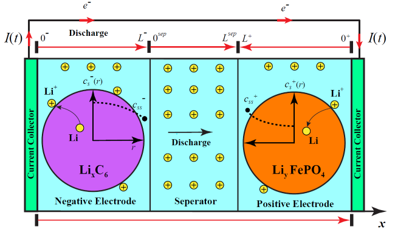

Assess new battery thermal management technologies

Approach

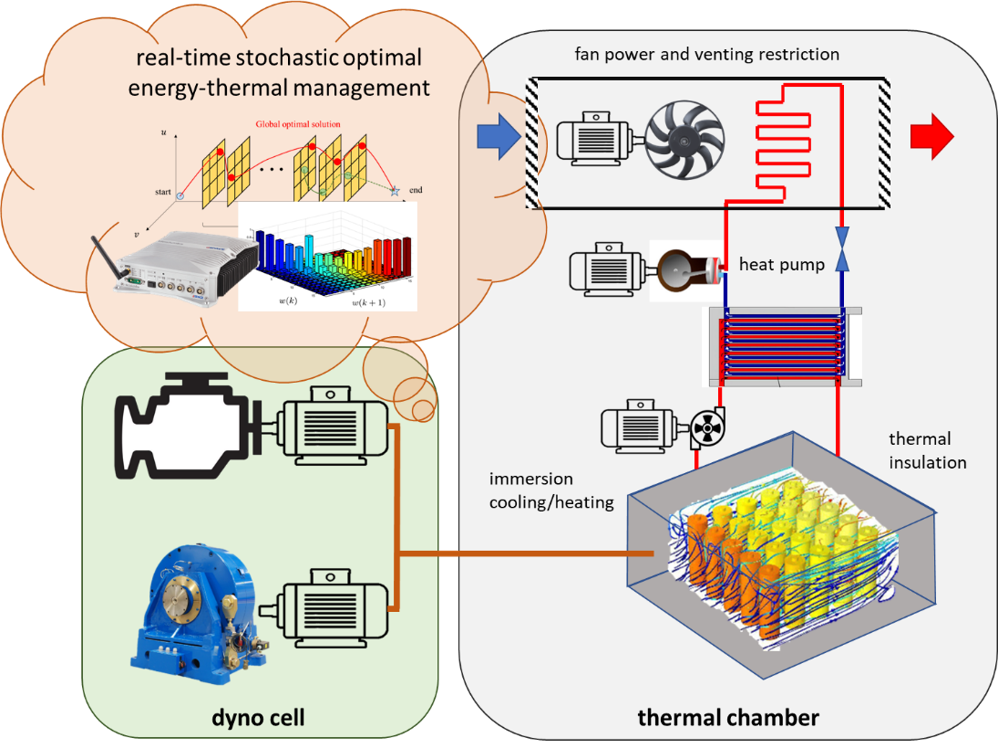

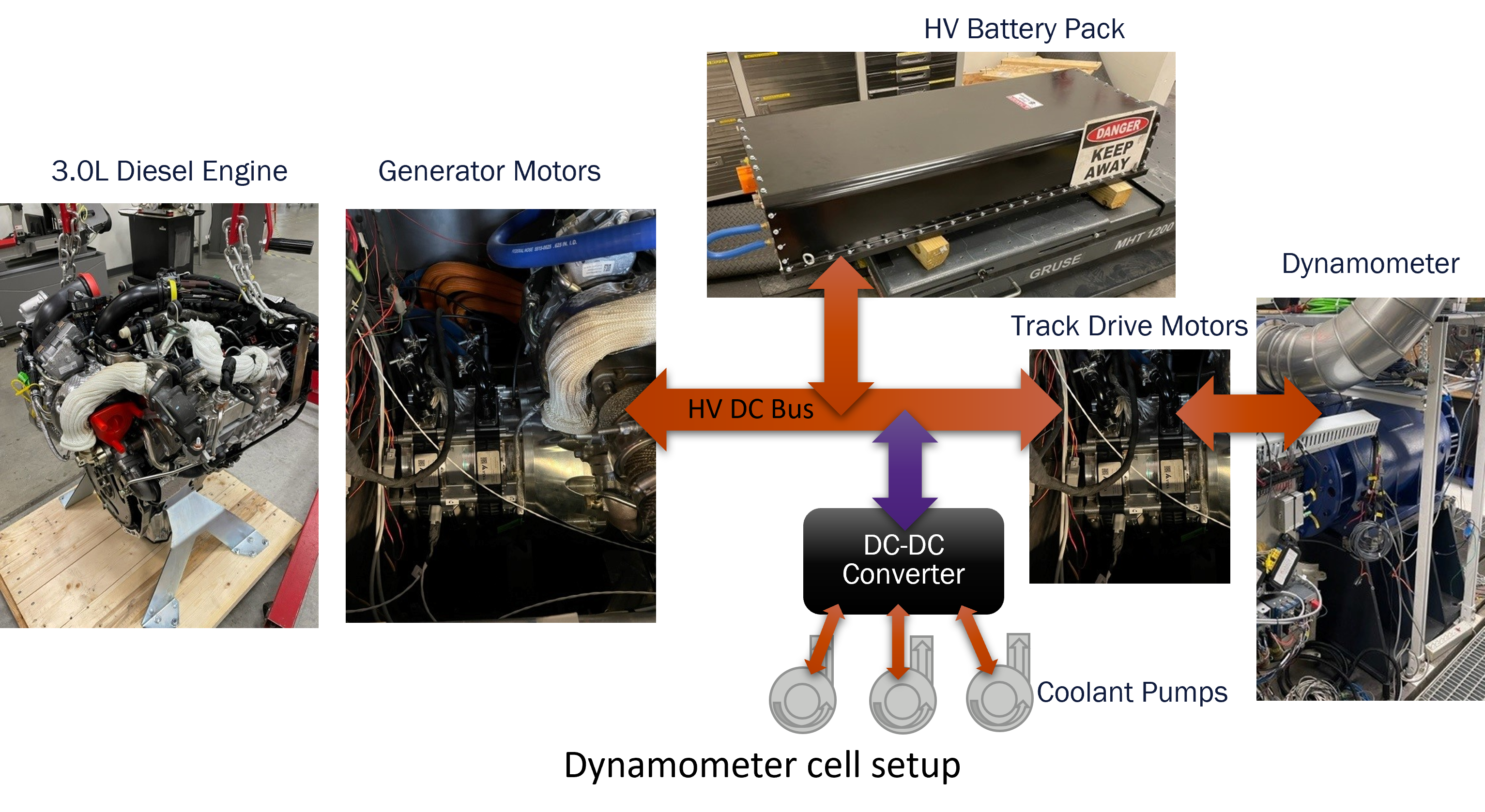

Test Bench Modification: Enhance a series hybrid powertrain for battery thermal control and validate strategies.

Model Enhancement: Integrate chemical-thermal dynamics and heat pump systems into powertrain models.

Real-Time Strategy: Develop energy-thermal management strategies considering preview uncertainties.

Technology Evaluation: Assess heat pump, thermal insulation, and immersive cooling for off-road vehicles.

Contact Us

Qilun Zhu, Ph.D.Research Associate Professorqilun@clemson.edu(864) 283-72394 Research DriveGreenville, SC 29607