Most publications can be accessed through Clemson TigerPrints or Researchgate.

Email to request something not found there.

Books

B01. Salandro, W., Jones, J., Bunget, C., Mears, L., Roth, J.T. (2015). Electrically-Assisted Forming: Modeling and Control (Springer series in Advanced Manufacturing). ISBN 978-3-319-08878-5, Springer-Verlag: London, 355 pp.

Book Chapters

BC02. Mears, L., Ziegert, J., Roth, J., Morkos, B. (2019). “Manufacturing Quality Assessment and Control,” chapter in Handbook of Manufacturing. World Scientific: Singapore, 39 pp.

BC01. Gill, J., Chen, Y., Akhavan Niaki, F., Tomaszewski, M., Wang, W., Mears, L., Pisu, P., Jia, Y., Krovi, V. (2019). “A Smart Companion Robot for Automotive Assembly,” chapter in Recent Advances in Industrial Robotics. World Scientific: Singapore, 28 pp.

Patents

P22. Grimm, T., Mears, L. (2019). “Novel Toolpathing Strategy for Incremental Forming,” Invention Disclosure 2020-006, Clemson University, presented 25July2019.

P21 Roth, J., Grimm, T., Flanagan, S., Allison, B., Meleen, D. (2019). “Method of Etching Core Grains in Heat Treated and Carburized P675,” Invention Disclosure 2019-SRA023, Penn State University, presented 9Jul2019.

P20. Roth, J., Grimm, T., Flanagan, S., Allison, B., Meleen, D. (2019). “Method of Etching Case Carburized Martensitic Stainless Steel for Microstructural Evaluation of the Case Grains,” Invention Disclosure 2019-SRA022, Penn State University, presented 9Jul2019.

P19. Grimm, T., Mears, L. (2019). “Method of Accuracy Improvement in Single Point Incremental Forming,” Invention Disclosure 2019-045, Clemson University, presented 11Apr2019.

P18. Grimm, T., Kulkarni, S., Mears, L. (2019). “Sacrificial Backing Sheet Use in Single Point Incremental Forming,” Invention Disclosure 2019-041, Clemson University, presented 02Apr2019.

P17 Grimm, T., Shafer, D., Ragai, I. (2019). “Use of Complex Toolpaths in Friction Stir Welding,” Invention Disclosure 2019-4877, Penn State University, presented 6Feb2019.

P16. Grimm, T., Mears, L., Akhavan Niaki, F. (2019). “Modification to circular/trochoidal milling toolpath,” Invention Disclosure 2019-030, Clemson University, presented 29Jan2019.

P15. Grimm, T., Mathis, G., Mears, L., Ruszkiewicz, B. (2019). “Method of electrical isolation of machine spindle,” Invention Disclosure 2019-031, Clemson University, presented 28Jan2019.

P14 Roth, J., Grimm, T., Flanagan, S., Allison, B., Meleen, D. (2018). “Method of Etching Martensitic Stainless Steel for Microstructural Evaluation,” Invention Disclosure 2018-4846, Penn State University, presented 14Nov2018.

P13 Roth, J., Grimm, T., Flanagan, S., Allison, B., Meleen, D. (2018). “Apparatus for Etching Martensitic Stainless Steel for Microstructural Evaluation,” Invention Disclosure 2018-4845, Penn State University, presented 14Nov2018.

P12 Grimm, T., Ragai, I. (2018). “Use of a Novel Lubricant in Electrically Assisted Manufacturing Processes,” Invention Disclosure 2018-4835, Penn State University, presented 31Oct2018.

P11. Roth, J., Grimm, T., Ragai, I. (2018). “Complex Toolpathing in Incremental Forming,” Invention Disclosure 2018-4781, Penn State University, presented 21Jun2018.

P10. Krugh, M., Mears, L. (2017). “Assembly Vision Assist Glove,” Invention Disclosure 2018-043, Clemson University, presented 01Sep2017.

P09. Krugh, M., Mears, L. (2017). “Assembly Sensor Assist Glove,” Invention Disclosure 2018-042, Clemson University, presented 01Sep2017.

P08. Krugh, M., Mears, L. (2017). “Clemson Pi Camera (CPIC),” Invention Disclosure 2018-044, Clemson University, presented 25May2017.

P07. Roth, J., Grimm, T., Craig, G. (2017, 2019). “New Incremental Forming Tools and Method,” U.S. Patent 62311689, filed 22Mar2017, issued 4Apr2019.

P06. Ruszkiewicz, B., Skovron, J., Mears, L. (2017). “Electrically Assisted Flow Drill Screwing Process (FDS) and Fixturing”, U.S. Provisional Patent No. 62/460,462, filed 27Feb2017, full filing 19Feb2018.

P05. Roth, T., Grimm, T. (2017). “Complex Tooling Method: Undercut Incremental Forming via Tooling Geometry,” Invention Disclosure 2017-4568, Penn State, Presented 23Feb2017.

P04. Ruszkiewicz, B., Skovron, J., Mears, L. (2016). “Electrically Assisted Self Piercing Rivets (SPR) and Fixturing,” Invention Disclosure 2017-034, Clemson University, presented 17Feb2017.

P03. Ruszkiewicz, B., Mears, L. (2016). “Electrically Assisted Drilling and Milling of Metallic Materials”, Invention Disclosure 2016-030, Clemson University, presented 21Oct2016.

P02. Salandro, W., Bunget, C., Mears, L. (2011). “Thermo-Mechanical Predictive Algorithm for Electrically-Assisted Manufacturing Process,” U.S. Provisional Patent No. 61/487447, filed 18May2011.

P01. Mears, L. and Martens, T. (2010, 2014). “Microstructure-Enhanced Sinter Bonding of Metal Injection Molded (MIM) Parts to Solid Substrate,” U.S. Patent 8871355, filed 10Aug2010, issued 28Oct2014.

Refereed Journal Publications

J64. Shaffer, D., Grimm, T. J., Ragai, I., Roth, J. (2019). “Utilization of XSYTIN-1 Tool in Electrically-Assisted Friction Stir Welding of Dissimilar Metals-Al 6061-T651 to Mild Steel,” Advanced Materials Research (Vol. 1152, pp. 31-41).

J63. Lynch, P., & Grimm, T. (2019). Reducing Microsegregation in Next-Generation High-Strength Low-Alloy Cast Steels. International Journal of Metalcasting, 1-10.

J62. Pearce, B.W., Antani, K., Mears, L., Funk, K., Mayorga, M. (2019). “An effective integer program for a general assembly line balancing problem with parallel workers and additional assignment restrictions,” SME Journal of Manufacturing Systems, 50(1): 180-192, doi:10.1016/j.jmsy.2018.12.011.

J61. Pleta, A., Akhavan Niaki, F., Mears, L. (2018). “Investigating a new unified approach for determining cutting force coefficients in trochoidal milling of IN718 nickel-based superalloy with respect to tool wear state,” ASME Journal of Manufacturing Science and Engineering, Submitted.

J60. Akhavan Niaki, F., Pleta, A., Mears, L., Wiederkehr, P. (2018). “Trochoidal Milling: Investigation of Dynamic Stability and Time Domain Simulation in an Alternative Path Planning Strategy,” International Journal of Advanced Manufacturing Technology, Accepted.

J59. Ruszkiewicz, B., Skovron, J., Absar, S., Choi, H., Zhao, X., Mears, L., Abke, T., Ipekbayrak, K. (2018). “Parameter Sensitivity and Process Time Reduction for Friction Element Welding of 6061-T6 Aluminum to 1500MPa Press-Hardened Steel,” SAE International Journal of Materials and Manufacturing, 12(1):2019, doi:10.4271/05-12-01-0004.

J58. Akhavan Niaki, F., Pleta, A., Mears, L. (2018). “Trochoidal Milling: Investigation of a New Approach on Chip Thickness Modeling and Cutting Force Simulation in an Alternative Path Planning Strategy,”International Journal of Advanced Manufacturing Technology, Accepted.

J57. Ruszkiewicz, B., Gendreau, E., Akhavan Niaki, F., Mears, L. (2017). “Electroplastic Drilling of Low and High Strength Steels,” ASME Journal of Manufacturing Science and Engineering, Accepted.

J56. Ruszkiewicz, B., Mears, L. (2017). “Investigation of Heterogeneous Joule Heating as the Explanation for the Transient Electroplastic Stress Drop in Pulsed Tension of 7075-T6 Aluminum,” ASME Journal of Manufacturing Science and Engineering, doi:10.1115/1.4040349, 140(9): 091014-091014-11. doi:10.1115/1.4040349.

J55. Krugh, M., Mears, L. (2018). “A complementary Cyber-Human Systems framework for Industry 4.0 Cyber-Physical Systems,” Manufacturing Letters, 15B(1):89-92, doi: 10.1016/j.mfglet.2018.01.003.

J54. Akhavan Niaki, F., Ul Haq, A., Djurdjanovic, D., Mears, L., Li, L. (2017). “Process and Operations Control in Modern Manufacturing,” ASME Journal of Manufacturing Science and Engineering, 140(1):060010.1-060010.18, doi: 10.1115/1.4038074.

J53. Akhavan Niaki, F., Mears, L., (2017). “A Comprehensive Study on the Effects of Tool Wear on Surface Roughness, Dimensional Integrity and Residual Stress in Turning IN718 Hard-to-Machine Alloy,” SME Journal of Manufacturing Systems, 30(1):268-270.

J52. Ruszkiewicz, B., Grimm, T., Ragai, I., Mears, L., Roth, J. (2017). “A Review of Electrically-Assisted Manufacturing with Emphasis on Modeling and Understanding of the Electroplastic Effect,” ASME Journal of Manufacturing Science and Engineering, 139(11), 110801, doi: 10.1115/1.4036716.

J51. Kuttolamadom, M., Jones, J., Mears, L., von Oehsen, J., Kurfess, T., Ziegert, J. (2017). “High Performance Computing Simulations to Identify Process Parameter Designs for Profitable Titanium Machining,” SME Journal of Manufacturing Systems: Special issue on High-Performance Computing and Data Analytics for Cybermanufacturing, 43(2):235-247, doi: 10.1016/j.jmsy.2017.02.014.

J50. Patel, A., Andrews, P., Summers, J., Harrison, E., Schulte, J., Mears, L. (2016). “Evaluating the Use of Artificial Neural Networks and Graph Complexity to Predict Automotive Assembly Quality Defects,” ASME Journal of Computing and Information Science in Engineering, 17(3): 031017-26, doi: 10.1115/1.4037179.

J49. Mehta, P., Kuttolamadom, M., Mears, L. (2016). “Mechanistic Force Model for Machining Process – Theory and Application of Bayesian Inference,” International Journal of Advanced Manufacturing Technology, 91(9-12):3673–3682, doi: 10.1007/s00170-017-0064-0.

J48. Gill, A., Visotsky, D., Mears, L., Summers, J. (2016). “Cost Estimation Model for PAN-Based Carbon Fiber Manufacturing Process,” ASME Journal of Manufacturing Science and Engineering, 139(4):041011-041011-8, doi: 10.1115/1.4034713.

J47. Akhavan Niaki, F., Michel, M., Mears, L. (2016). “State of Health Monitoring in Machining: Extended Kalman Filter for Tool Wear Assessment in Turning of IN718 Hard-to-Machine Alloy,” SME Journal of Manufacturing Processes, 24(2): 361-369 doi:10.1016/j.jmapro.2016.06.015.

J46. Chen, Y., Bunget C., Mears, L., Kurfess T. (2016). “Investigations in Subsurface Damage when machining γ′-strengthened nickel-based superalloy,” Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 230(7):1221-1233 doi: 10.1177/0954405415577055. (Winner of the IMECHE Thatcher Bros. Prize)

J45. Feng, L., Mears, L., Beaufort, C., Schulte, J. (2016) “Energy, economy, and environment analysis and optimization on manufacturing plant energy supply system,” Energy Conversion and Management, 117(1): 454-465, doi:10.1016/j.enconman.2016.03.031.

J44. Akhavan Niaki, F., Ulutan, D., Mears, L. (2016). “Parameter Inference under Uncertainty in End-Milling γ’-Strengthened Difficult-to-Machine Alloy,” ASME Journal of Manufacturing Science and Engineering, 138(1):061014, doi:10.1115/1.4033041

J43. Akhavan Niaki, F., Mears, L. (2016). “A Probabilistic-Based Study on Fused Direct and Indirect Methods for Tracking Tool Flank Wear of Rene-108 Nickel-Based Alloy,” Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, pp. 1-14, doi: 10.1177/0954405416683432.

J42. Feng, L., Mears, L. (2016), “Energy Consumption Modeling and Analyses in Automotive Manufacturing Plant,” ASME Journal of Manufacturing Science and Engineering: Special Issue on Sustainable Manufacturing, 138(10):101005-101015, doi: 10.1115/1.4034302.

J41. Ruszkiewicz, B., Mears, L. (2016), “Temperature-Controlled Forming of 7075-T6 Aluminum Using Linearly Decaying Direct Electric Current,” ASME Journal of Manufacturing Science and Engineering: Special Issue on Innovations in Materials Forming Processes, 138(9): 091009-091018.

J40. Akhavan Niaki, F., Ulutan, D., Mears, L. (2015). “Stochastic Tool Wear Assessment in Milling Difficult to Machine Alloys,” International Journal of Mechatronics and Manufacturing Systems, 8(3-4):134-159, doi:10.1504/IJMMS.2015.073090.

J39. Akhavan Niaki, F., Feng, L., Ulutan, D., Mears, L. (2015). “A Wavelet Based Data-Driven Modeling for Tool Wear Assessment of Difficult to Machine Materials,” International Journal of Mechatronics and Manufacturing Systems, 9(2):97-121.

J38. Skovron, J., Mears, L., Ulutan, D., Detwiler, D., Paolini, D., Baemler, B., Claus, L. (2015). “Effect of Thermal Assistance on the Joint Quality of Al6063-T5A During Flow Drill Screwdriving,” ASME Journal of Manufacturing Science and Engineering, 137(5):051019, doi:10.1115/1.4031242.

J37. Mehta, P., Mears, L. (2015). “Adaptive control for multistage machining process scenario – bar turning with varying material properties,” International Journal of Advanced Manufacturing Technology, 78(5-8): 1265-1273; doi: 10.1007/s00170-014-6739-x.

J36. Skovron, J., Mears, L., Ulutan, D., Detwiler, D., Baemler, B., Claus, L. (2015). “Characterization of Flow Drill Screwing Process Parameters on Joint Quality,” SAE International Journal of Materials and Manufacturing, 8(1):35-41; doi:10.4271/2014-01-2241.

J35. Mears, L., Kurfess, T., Kuttolamadom, M., Mehta, P. (2014). “The Correlation of the Volumetric Wear Rate of Turning Tool Inserts with Carbide Grain Sizes,” ASME Journal of Manufacturing Science and Engineering, 137(1): 011015-1 – 011015-8; doi:10.1115/1.4028129.

J34. Mears, L., Kurfess, T., Kuttolamadom, M., Mehta, P. (2014). “Correlation of the Volumetric Tool Wear Rate of Carbide Milling Inserts with the Material Removal Rate of Ti-6Al-4V,” ASME Journal of Manufacturing Science and Engineering, 137:021021-1 – 021021-8; doi:10.1115/1.4028129.

J33. Jones, J.J., L. Mears (2013). “Alternative Control of an Electrically Assisted Tensile Forming Process Using Current Modulation,” ASME Journal of Manufacturing Science and Engineering: Special issue on Thermally-Assisted Manufacturing, 135(6):061004-061011; doi:10.1115/1.4025566

J32. Mehta, P., Werner, A., Mears, L. (2013). “Condition based maintenance: Systems integration and intelligence using Bayesian classification and sensor fusion,”Journal of Intelligent Manufacturing,26(1):331-346, doi:10.1007/s10845-013-0787-1.

J31. Jones, J.J., Mears, L. (2013). “Thermal Response Modeling of Sheet Metals in Uniaxial Tension During Electrically-Assisted Forming,” ASME Journal of Manufacturing Science and Engineering, 135(2):021011-1 – 021011-11; doi:10.1115/1.4023366.

J30. Martens, T., Mears, L. (2013). “Direct Sinter Bonding of Metal Injection-Molded Parts to Solid Substrate through Use of Deformable Surface Microfeatures,” ASME Journal of Micro- and Nano-Manufacturing, 1(1): 011008 (9 pages); doi:10.1115/1.4023532.

J29. Maier, J., Mears, M., Summers, J., (2013). “Design of an Apparatus to Detect Small Changes in Mass of Rotational Machine Components”, International Journal of Modern Engineering. 13(2):5-16.

J28. Bunget, C., Salandro, W., Mears, L. (2012). “Thermomechanical modeling sensitivity analysis of electrically assisted forming,” Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture,227(8):1089-1098.

J27. Montes, C., Wong, C., Ziegert, J., Mears, L. (2012). “Vision-based tracking of a dynamic target with application to multi-axis position control,” Journal of Real-Time Image Processing., 10(1): 119-134, doi:10.1007/s11554-012-0260-y.

J26. Morkos, B., Taiber, J., Summers, J., Mears, L., Fadel, G., Rilka, T. (2012). “Mobile devices within manufacturing environments: a BMW applicability study,” International Journal on Interactive Design and Manufacturing. 6(2): 101-111; doi:10.1007/s12008-012-0148-x.

J25. Jones, J.J., Mears, L., and Roth, J.T. (2012). “Electrically-Assisted Forming of Magnesium AZ31: Effect of Current Magnitude and Deformation Rate on Forgeability,” ASME Journal of Manufacturing Science and Engineering.134: 034504-1 – 034504-7; doi:10.1115/1.4006547.

J24. Kuttolamadom, M., Jones, J., Mears, L., Kurfess, T., Funk, K. (2012). “Life-Cycle Integration of Titanium Alloys into the Automotive Segment for Vehicle Light-Weighting: Part II – Component Life-Cycle Modeling and Cost Justification,” SAE International Journal of Materials and Manufacturing, 5(1):260-269; doi:10.4271/2012-01-0785.

J23. Jones, J., Kuttolamadom, M., Mears, L., Kurfess, T., Funk, K. (2012). “Life-Cycle Integration of Titanium Alloys into the Automotive Segment for Vehicle Light-Weighting: Part I – Component Redesign, Prototyping, and Validation,” SAE International Journal of Materials and Manufacturing, 5(1):247-259; doi:10.4271/2012-01-0785.

J22. Mears, L., Mehta, P., Kuttolamadom, M., Montes, C., Jones, J., Salandro, W., Werner, A. (2012). “Manufacturing Process Modeling and Application to Intelligent Control,” Journal of the South Carolina Academy of Science, Governor’s special issue, 10(1):13-18.

J21. Kuttolamadom, M., Mears, L., Kurfess, T.R. (2012). “On the Volumetric Assessment of Tool Wear in Machining Inserts with Complex Geometries – Part 2: Experimental Investigation & Validation on Ti-6Al-4V,” ASME Journal of Manufacturing Science and Engineering, 134(5): 051003-1 – 051003-9; doi:10.1115/1.4007294.

J20. Kuttolamadom, M., Mears, L., Kurfess, T.R. (2012). “On the Volumetric Assessment of Tool Wear in Machining Inserts with Complex Geometries – Part 1: Need, Methodology & Standardization,” ASME Journal of Manufacturing Science and Engineering, 134(5): 051002-1 – 051002-8; doi:10.1115/1.4007184.

J19. Salandro, W., Bunget, C., Mears, L. (2012). “A Thermal-Based Approach for Determining Electroplastic Characteristics,” Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture. 225(5): 775-788. (Winner of the SAGE Best Paper Prize 2012 and IMECHE George Stephenson Gold Medal)

J18. Bunget, C., Salandro, W., Mears, L. (2011). “Several Factors Affecting the Electroplastic Effect During an Electrically-Assisted Forming Process,” ASME Journal of Manufacturing Science and Engineering Special Issue on Forming Technologies, 133(6):064503-1 – 064503-5; doi:10.1115/1.4004950.

J17. Salandro, W., Bunget, C., Mears , L. (2011). “Electroplastic Modeling of Bending Stainless Steel Sheet Metal Using Energy Methods,” ASME Journal of Manufacturing Science and Engineering, 133(4):041008-1 – 041008-10; doi:10.1115/1.4004589.

J16. Bunget, C., Salandro, W., Mears, L. (2011). “Evaluation of Lubricants for Electrically-Assisted forming,” Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture; 225:1-11, doi:10.1177/0954405411401267.

J15. Martens, T., Mears , L., Dotson, M., Sanger , P., Graham, M. (2011). “Use of Fused Deposition Modeling of Polyphenylsulfone for Centrifugal Casting of Polyurethane: Material, Surface and Process Considerations,” ASME Journal of Manufacturing Science and Engineering, 133(5):051003-1 – 051003-10; doi:10.1115/1.4004848.

J14. Kuttolamadom, M., Hamzehlouia, S., Mears, L. (2010). “Effect of Machining Feed on Surface Roughness in Cutting 6061 Aluminum,” SAE International Journal of Materials and Manufacturing, 3(1):108-119.

J13. McDonnell, D., Mayorga, M., Benson, L., Mears, L. (2010). “Motivating industrial engineering students: The effects of authentic learning experience, gender and class standing,” Journal of Applications and Practices in Engineering Education, 1(2):79-98.

J12. Bunget, C., Salandro, W., Mears, L., Roth, J.T., (2010). “Energy-Based Modeling of an Electrically-Assisted Forging Process,” Transactions of the North American Manufacturing Research Institute of SME, 38(1):647-654.

J11. Jones, J.J., Mears, L., Roth, J.T., (2010). “Empirical Modeling of the Stress-Strain Relationship for Upsetting Under Direct Electrical Current,” Transactions of the North American Manufacturing Research Institute of SME, 38(1):451-458.

J10. Roth, J., Djurdjanovic, D.,Yang, X., Mears, L., Kurfess, T. (2009). “Quality and Inspection of Machining Operations: Tool Condition Monitoring,” ASME Journal of Manufacturing Science and Engineering, 132(4):041015-1 – 011015-16; doi:10.1115/1.4002022.

J09. Mears, L., Omar, M., Kurfess, T. (2009). “Automotive Engineering Curriculum Development: Case study for Clemson University,” Journal of Intelligent Manufacturing: Special Issue on Intelligent Manufacturing Systems,22(5):693-708 doi:10.1007/s10845-009-0329-z.

J08. Mears, L., Roth, J., Djurdjanovic, D., Yang, X., Kurfess, T. (2009). “Quality and Inspection of Machining Operations: CMM Integration to the Machine Tool,” ASME Journal of Manufacturing Science and Engineering, 131(5):051006-1 – 051006-13; doi:10.1115/1.3184085.

J07. Omar, M., Mears, L., Kiggans, R., Kurfess, T. (2009). “Organizational Learning in Automotive Manufacturing: A Strategic Choice,” Journal of Intelligent Manufacturing: Special Issue on Intelligent Manufacturing Systems, 22(5): 709-715, doi:10.1007/s10845-009-0330-6.

J06. Montes, C.A., Ziegert, J.C., Mears, L. (2009). “Method to Measure Planar Displacement Using Centroid Calculation,” Transactions of the North American Manufacturing Research Institute of SME, 37(1):525-532.

J05. Mears, L., Kurfess, T. (2008). “Open-Loop Velocity Planning to Mitigate the Effect of Stiction in Pushing Positioning,” Transactions of the North American Manufacturing Research Institute of SME, 36(1):301-308.

J04. Grujicic, M., Sellappan, V., Mears, L., Seyr, N., Obieglo, A., Erdmann, M., Holzleitner, J. (2008). “Selection of the Spraying Technologies for Over-Coating of Metal Stampings with Thermoplastics for Use in Direct-Adhesion Polymer Metal Hybrid Load-Bearing Components,” Journal of Materials Processing Technology,198(1-3): 300-312.

J03. Mears, L., Kurfess, T. (2007). “Impulsive-Actuation Part Positioning through Constrained Energy Balance Planning,” Transactions of the North American Manufacturing Research Institute of SME, 35(1):521-528.

J02. Mears, M. L., Kolarits, F., Thompson, M., & Kurfess, T. R. (2007). “Design of a Flexible Centering Tooling System,” International Journal of Computer Applications in Technology, 28(1):52-62.

J01. Mears, L., Kurfess, T. (2006). “Application of a Linear Center Identification Scheme to Deterministic Polar Positioning,” Transactions of the North American Manufacturing Research Institute of SME, 34(1):619-625.

Refereed Conference Publications

C117. Grimm, T., Mears, L. (2019). “Simulation and Experimental Investigation of Scallop Removal Using Friction Stir Processing and Complex Toolpath,” Proceedings of ASME International Mechanical Engineering Conference and Exposition, Paper no. IMECE2019-11375, Accepted.

C116. Grimm, T., Mears, L. (2019). “Numerical Determination of Unconstrained Area Effect on Springback in Incremental Forming of 5052-H32 Aluminum,” Proceedings of ASME International Mechanical Engineering Conference and Exposition, Paper no. IMECE2019-11255, Accepted.

C115. Grimm, T., Mears, L. (2019). “Experimental Investigation of a Backing Sheet Stiffener in Incremental Forming of Polycarbonate,” Proceedings of ASME International Mechanical Engineering Conference and Exposition, Paper no. IMECE2019-11231, Submitted.

C114. Vedant, R., Garimella, R., Baburaj, A., Krugh, M., Mears, L. (2019). “Associate Finger Engagement During Manual Assembly in Automotive Production for Smart Wearable Systems,” Proceedings of 25th International Conference on Production Research 2019 (ICPR 2019), Accepted.

C113. Allen, M., Wescoat, E., Mears, L. (2019). “Determining optimal trajectories for Image Based Visual Servoing using Dynamic Programming,” Proceedings of 25th International Conference on Production Research 2019 (ICPR 2019), Accepted.

C112. Neelakanta Pillai, G., Eswar, V., Krugh, M., Mears, L. (2019). “Evaluation of Wearable Visual Assistance System for Manual Automotive Assembly,” Proceedings of 25th International Conference on Production Research 2019 (ICPR 2019), Accepted.

C111. Vedant, R., Krugh, M., Mears, L. (2019). “Measuring Finger Engagement During Manual Assembly Operations in Automotive Assembly,” Proceedings of SME North American Manufacturing Research Conference (NAMRC47), Paper no. NAMRC47-179, Erie, PA, USA, June 10-14, 2019.

C110. Grimm, T., Ragai, I. (2019). “An investigation of liquid metal lubrication during electrically-assisted incremental forming of titanium,” Proceedings of 2019 SME North American Manufacturing Research Conference (NAMRC47), Paper No. NAMRC47-118, Erie, PA, USA, June 10-14, 2019.

C109. Wescoat, E., Krugh, M., Henderson, A., Goodnough, J., Mears, L. (2019). “Vibration Analysis Utilizing Unsupervised Learning,” Proceedings of SME North American Manufacturing Research Conference (NAMRC47), Paper no. NAMRC47-73, Erie, PA, USA, June 10-14, 2019.

C108. Nithyanand, G., Pleta, A., Akhavan Niaki, F., Mears, L. (2019). “Identification of optimal machining parameters in trochoidal milling of Inconel 718 for minimal force and tool wear using the Taguchi method,” Proceedings of SME North American Manufacturing Research Conference (NAMRC47), Paper no. NAMRC47-165, Erie, PA, USA, June 10-14, 2019.

C107. Baskaran, S., Akhavan Niaki, F., Tomaszewski, M., Gill, J.S., Chen, Y., Jia, Y., Mears, L., Krovi, V. (2019). “Digital Human and Robot Simulation in Automotive Assembly using Siemens Tecnomatix Process Simulate: A Feasibility Study,” Proceedings of SME North American Manufacturing Research Conference (NAMRC47), Paper no. NAMRC47-155, Erie, PA, USA, June 10-14, 2019. (winner of NAMRC47 Student Research Presentation Award)

C106. Grimm, T., Ragai, I., Roth, J., (2018). “Utilization of Wavy Toolpath in Single-Point Incremental Forming,” Proceedings of ASME International Mechanical Engineering Conference and Exposition, Paper No. IMECE2018-86885, Pittsburgh, PA, USA, November 9-15, 2018.

C105. Varma, A., Absar, S., Skovron, J., Ruszkiewicz, B., Abke, T., Mears, L., Choi, H., Zhao, X. (2018). “Thermal-Mechanical Numerical Modeling of the Friction Element Welding Process,” Proceedings of ASME Manufacturing Science and Engineering Conference (MSEC2018), Paper No. MSEC2018-6692, Texas A&M University, USA, June 18 – 22, 2018.

C104. Pleta, A., Akhavan Niaki, F., Mears, L. (2018). “A Comparative Study on the Cutting Force Coefficient Identification between Trochoidal and Slot Milling,” Proceedings of SME North American Manufacturing Research Conference (NAMRC46), Paper No. NAMRC46-191, Texas A&M University, USA, June 18 – 22, 2018.

C103. Joshi, N., Singh, S., Krugh, M., Mears, L. (2018). “Background Noise Mitigation of Dual Microphone System for Defect Detection in Electrical Cable Connection,”Proceedings of SME North American Manufacturing Research Conference (NAMRC46), Paper No. NAMRC46-188, Texas A&M University, USA, June 18 – 22, 2018.

C102. Ruszkiewicz, B., Mears, L. (2018). “Investigation of the Electroplastic Effect through Nominally Equal Energy Deformation,” Proceedings of ASME Manufacturing Science and Engineering Conference (MSEC2018), Paper No. MSEC2018-6250, Texas A&M University, USA, June 18 – 22, 2018.

C101. Absar, S., Ruszkiewicz, B., Skovron, J., Mears, L., Abke, T., Zhao, X., Choi, H. (2018). “Temperature Measurement in Friction Element Welding Process with Micro Thin Film Thermocouples,” Proceedings of SME North American Manufacturing Research Conference (NAMRC46), Paper No. NAMRC46-138, Texas A&M University, USA, June 18 – 22, 2018.

C100. Grimm, T., Ragai, I., Roth, J., (2017). “Feasibility of Past Vertical Forming Utilizing Single Point Incremental Sheet Forming,” Proceedings of ASME International Mechanical Engineering Conference and Exposition, Paper No. IMECE2017-71069, Tampa, FL, USA, November 3-9, 2017.

C099. McGee, E., Krugh, M., McGregor, J., Mears, L. (2017). “Designing for Reuse in an Industrial Internet of Things Monitoring Application,” Proceedings of 2nd Workshop on Social, Human, and Economic Aspects of Software, Salvador, Brazil, 29-31 May 2017.

C098. Akhavan Niaki, F., Ul Haq, A., Djurdjanovic, D., Mears, L., Li, L. (2017). “Process and Operations Control in Modern Manufacturing,” Proceedings of ASME 12th Int’l Conference on Manufacturing Science and Engineering (MSEC2017), Paper No. MSEC2017-3104, Los Angeles, California, June 4 – 8, 2017.

C097. Grimm, T., Ragai, I., Roth, J. (2017). “A Novel Modification to the Incremental Forming Process, Part 1: Multi-Directional Tooling,” Proceedings of 2017 SME North American Manufacturing Research Conference (NAMRC45), Paper No. NAMRC45-510, Los Angeles, CA, USA, June 4 – 8, 2017.

C096. Grimm, T., Ragai, I., Roth, J. (2017). “A Novel Modification to the Incremental Forming Process, Part 2: Validation of the Multi-Directional Tooling Method,” Proceedings of 2017 SME North American Manufacturing Research Conference (NAMRC45), Paper No. NAMRC45-520, Los Angeles, CA, USA, June 4 – 8, 2017.

C095. Grimm, T., Ragai, I., Roth, J. (2017). “Optimum Process Parameters for Springback Reduction of Single Point Incrementally Formed Polycarbonate,” Proceedings of 2017 SME North American Manufacturing Research Conference (NAMRC45), Paper No. NAMRC45-329, Los Angeles, CA, USA, June 4 – 8, 2017.

C094. Pleta, A., Mears, L. (2017). “Investigation of Chip Thickness of Trochoidal Milling in Nickel-Based Superalloy,” Proceedings of 2017 SME North American Manufacturing Research Conference (NAMRC45), Paper No. NAMRC45-144, Los Angeles, California, June 4 – 8, 2017.

C093. Krugh, M., McGee, E., McGee, S., Mears, L., Ivanco, A., Podd, K.C., Watkins, B. (2017). “Measurement of Operator-Machine Interaction on a Chaku-Chaku Assembly Line,” Proceedings of 2017 SME North American Manufacturing Research Conference (NAMRC45), Paper No. NAMRC45-146, Los Angeles, California, June 4 – 8, 2017.

C092. Skovron, J., Ruszkiewicz, B., Mears, L., Abke, T., Varma, A., Li, Y., Choi, H., Zhao, X. (2017). “Investigation of the Cleaning and Welding Steps from the Friction Element Welding Process,” Proceedings of ASME 12th Int’l Conference on Manufacturing Science and Engineering (MSEC2017), Paper No. MSEC2017-2786, Los Angeles, California, June 4 – 8, 2017.

C091. Karumatt, N., Ruszkiewicz, B., Mears, L. (2017). “Electrically Assisted Drilling of USIBOR 1500 Boron Steel And Its Implications for Electrically Assisted Manufacturing,”Proceedings of ASME 12th Int’l Conference on Manufacturing Science and Engineering (MSEC2017), Paper No. MSEC2017-3046, Los Angeles, California, June 4 – 8, 2017.

C090. Grimm, T., Ragai, I., Roth, J. (2017). “The Effects of Polarity and Current Path in Electrically Assisted Single Point Incremental Forming of 2024-T3 Aluminum,” Proceedings of ASME 12th International Manufacturing Science and Engineering Conference (MSEC2017), Paper No. MSEC2017-3037, Los Angeles, CA, USA, June 4 – 8, 2017.

C089. Ruszkiewicz, B., Gendreau, E., Akhavan Niaki, F., Mears, L. (2017). “Modeling the Electroplastic Effect in Electrically-Assisted Drilling of Mild Steel,” Proceedings of ASME 12th Int’l Conference on Manufacturing Science and Engineering (MSEC2017), Paper No. MSEC2017-2766, Los Angeles, California, June 4 – 8, 2017.

C088. Feng, L., Mears, L., Pisu, P., Schulte, J. (2017). “Nonlinear Parameter Estimation in a Typical Industrial Air Handler Unit,” Proceedings of ASME 12th Int’l Conference on Manufacturing Science and Engineering (MSEC2017), Paper No. MSEC2017-2994, Los Angeles, California, June 4 – 8, 2017.

C087. Feng, L., Mears, L., Schulte, J. (2016). “Key Variable Analysis and Identification on Energy Consumption of Automotive Manufacturing Plant,” Proceedings of 2016 IEEE Conference on Technologies for Sustainability (SusTech), Phoenix, Arizona, October 9 – 11, 2016.

C086. Rahman, S., Walker, I., Wang, Y., Mears, L., Pak, R., Remy, S. (2016). “Trust-Based Human-Robot Collaborative Assembly and Handovers in Flexible Manufacturing,” Proceedings of 2016 IEEE Conference on Automation Science and Engineering (IEEE CASE), Fort Worth, TX, USA, August 21-24, 2016, Paper #102.

C085. Neveux, T., Ruszkiewicz, B., Grimm, T., Roth, J. (2016). “Electrically Assisted Global Springback Elimination After Single Point Incremental Forming,” Proceedings of ASME 11th International Manufacturing Science and Engineering Conference (MSEC2016), Paper No. MSEC2016-8813, Blacksburg, VA, USA, June 27 – July 1, 2016.

C084. Grimm, T., Roth, J., Ragai, I. (2016). “Electrically Assisted Global Springback Elimination in AMS-T-9046 Titanium After Single Point Incremental Forming,” Proceedings of ASME 11th International Manufacturing Science and Engineering Conference (MSEC2016), Paper No. MSEC2016-8811, Blacksburg, VA, USA, June 27 – July 1, 2016.

C083. Niebauer, J., Grimm, T., Shaffer, D., Sweeney, I., Ragai, I., Roth, J. T. (2016). “Effect of Applied Electricity on Springback During Bending and Flattening of 304/316 Stainless Steel, Titanium AMS-T-9046 and Magnesium AZ31B,” Proceedings of ASME 11th International Manufacturing Science and Engineering Conference (MSEC2016), Paper No. MSEC2016-8810, Blacksburg, VA, USA, June 27 – July 1, 2016.

C082. Gill, A., Visotsky, D., Mears, L., Summers, J. (2016). “Cost Estimation Model for PAN-Based Carbon Fiber Manufacturing Process,” Proceedings of ASME 11thInternational Conference on Manufacturing Science and Engineering (MSEC2016), Paper No. MSEC2016-8724, Blacksburg, VA, USA, June 27 – July 1, 2016.

C081. Akhavan Niaki, F., Michel, M., Mears, L. (2016). “Extended Kalman Filter for Stochastic Tool Wear Assessment in Turning of INC718 Hard-to-Machine Alloy,” Proceedings of 2016 SME North American Manufacturing Research Conference (NAMRC44), Paper No. NAMRC44-23, Blacksburg, VA, USA, June 27 – July 1, 2016.

C080. Pleta, A., Mears L. (2016). “Cutting Force Investigation of Trochoidal Milling in Nickel-Based Superalloy,” Proceedings of 2016 SME North American Manufacturing Research Conference (NAMRC44), Paper No. NAMRC44-128, Blacksburg, VA, USA, June 27 – July 1, 2016.

C079. Khal, A., Ruszkiewicz, B., Mears, L. (2016). “Springback Evaluation of 304 Stainless Steel in an Electrically Assisted Air Bending Operation,” Proceedings of ASME 11thInternational Conference on Manufacturing Science and Engineering (MSEC2016), Paper No. MSEC2016-8736, Blacksburg, VA, USA, June 27 – July 1, 2016.

C078. Krugh, M., Mears, L. (2016). “Prediction of Defect Propensity for the Manual Assembly of Automotive Electrical Connectors,” Proceedings of 2016 SME North American Manufacturing Research Conference (NAMRC44), Paper No. NAMRC44-119, Blacksburg, VA, USA, June 27 – July 1, 2016.

C077. Skovron, J., Ruszkiewicz, B., Mears, L., Abke, T. (2016). “Effect of Electrical Augmentation on the Joining of Al6063-T5 Using Flow Drill Screws,” Proceedings of ASME 11th International Conference on Manufacturing Science and Engineering (MSEC2016), Paper No. MSEC2016-8578, Blacksburg, VA, USA, June 27 – July 1, 2016.

C076. Ruszkiewicz, B., Mears, L. (2016). “Temperature-Controlled Forming of 7075-T6 Aluminum Using Linearly Decaying Direct Electric Current,” Proceedings of ASME 11thInternational Conference on Manufacturing Science and Engineering (MSEC2016), Paper No. MSEC2016-8555, Blacksburg, VA, USA, June 27 – July 1, 2016.

C075. Ruszkiewicz, B., Mears, L. (2016). “Electrically-Assisted Compression of Tungsten Carbide and its Implications for Electrically-Assisted Machining,” Proceedings of ASME 11thInternational Conference on Manufacturing Science and Engineering (MSEC2016), Paper No. MSEC2016-8554, Blacksburg, VA, USA, June 27 – July 1, 2016.

C074. Krugh, M., Mears, L. (2016). “Statistical modeling of defect propensity in manual assembly as applied to automotive electrical connectors,” Proceedings of 6th CIRP Conference on Assembly Technologies and Systems (CATS), Gothenburg, Sweden, May 16-17, 2016.

C073. Akhavan Niaki, F., Pleta, A., Mears, L. (2015). “Superalloy Machining Tool Wear: State Estimation and Alternative Path Planning for Mitigation,” Proceedings of International Conference on Precision, Meso, Micro and Nano Engineering (COPEN9), Mumbai, India, 10-12 December 2015.

C072. Akhavan Niaki, F., Ulutan, D., Mears, L. (2015). “Wavelet Based Sensor Fusion for Tool Condition Monitoring of Hard to Machine Materials,” Proceedings of 2015 IEEE International Conference on Multisensor Fusion and Integration, San Diego, California, 14-16 September 2015.

C071. Walker, I., Wang, Y., Rahman, S., Pak, R., Remy, S., Mears, L. (2015). “Robot – Human Handovers Based on Trust”, Proceedings of the 2nd International Conference on Mathematics and Computers in Sciences and Industry (MSCI 2015), Paper no. 111646000005700000, pp. 119-124, doi 10.1109/MCSI.2015.50 Sliema, Malta, August 17-19, 2015.

C070. Feng, L., Ulutan, D., and Mears, L. (2015). “Energy consumption modeling and analyses in automotive manufacturing final assembly process,” Proceedings of 2015 IEEE Conference on Technologies for Sustainability (SusTech), Ogden, Utah, July 30-August 1, 2015.

C069. Akhavan Niaki, F., Ulutan, D., Mears, L. (2015). “In-Process Tool Flank Wear Estimation in Machining Gamma-Prime Strengthened Alloys Using Kalman Filter,” Proceedings of 43rd North American Manufacturing Research Conference (NAMRC43), Paper No. NAMRC43-0055, Charlotte, NC, USA, June 8-12, 2015.

C068. Pleta, A., Ulutan, D., Mears, L. (2015). “An Investigation of Alternative Path Planning Strategies for Machining of Nickel-Based Superalloys,” Proceedings of 43rd North American Manufacturing Research Conference (NAMRC43), Paper No. NAMRC43-0114, Charlotte, NC, USA, June 8-12, 2015.

C067. Ulutan, D., Pleta, A., Henderson, A., Mears, L. (2015). “Comparison and Cost Optimization of Solid Tool Life in End Milling Nickel-Based Superalloy,” Proceedings of 43rd North American Manufacturing Research Conference (NAMRC43), Paper No. NAMRC43-0108, Charlotte, NC, USA, June 8-12, 2015.

C066. Akhavan Niaki, F., Ulutan, D., Mears, L. (2015). “Parameter Estimation using Markov Chain Monte Carlo Method in Mechanistic Modeling of Tool Wear During Milling,” Proceedings of ASME 10thInternational Conference on Manufacturing Science and Engineering (MSEC2015),Paper No. MSEC2015-9357, Charlotte, NC, USA, June 8-12, 2015.

C065. Bardis, V., Akhavan Niaki, F., Ulutan, D., Mears, L. (2015). “Investigation of the Relationship Between Vibration Data and Tool Wear during End-Milling of Gamma Prime Strengthened Alloy,” Proceedings of ASME 10thInternational Conference on Manufacturing Science and Engineering (MSEC2015),Paper No. MSEC2015-9470, Charlotte, NC, USA, June 8-12, 2015.

C064. Feng, L., Mears, L. (2015). “Analysis of HVAC Energy in Automotive Paint Shop,” Proceedings of ASME 10thInternational Conference on Manufacturing Science and Engineering (MSEC2015), Paper No. MSEC2015-9281, Charlotte, NC, USA, June 8-12, 2015.

C063. Skovron, J., Ulutan, D., Mears, L., Detwiler, D., Paolini, D., Baemler, B., Claus, L. (2015). “Effect of Thermal Assistance on the Joining of Al6063 During Flow Drill Screwdriving,” Proceedings of ASME 10thInternational Conference on Manufacturing Science and Engineering (MSEC2015),Paper No. MSEC2015-9435, Charlotte, NC, USA, June 8-12, 2015.

C062. Ulutan, D., Pleta, A., Mears, L. (2015). “Electrically-Assisted Machining of Titanium Alloy Ti-6Al-4V and Nickel-Based Alloy IN-738: An Investigation,” Proceedings of ASME 10thInternational Conference on Manufacturing Science and Engineering (MSEC2015), Paper No. MSEC2015-9465, Charlotte, NC, USA, June 8-12, 2015.

C061. Feng, L., and Mears, L. (2015). “Time Series Analysis and Forecasting of Manufacturing Energy Demand,” Proceedings of the 2015 Industrial and Systems Engineering Research Conference, Nashville, Tennessee, May 30 – June 2, 2015.

C060. Skovron, J., Mears, L., Ulutan, D., Detwiler, D., Baemler, B., Claus, L. (2014). “Characterization of Flow Drill Screwing Process Parameters on Joint Quality,” Proceedings of 2014 SAE Aerospace Manufacturing & Automated Fastening Conference (AMAF), Paper number 2014-01-2241, Salt Lake City, UT, USA, September 23-25, 2014.

C059. Kuttolamadom, M., Mears, L. (2014). “Analysis of the Bulk Wear Volume of Turning Inserts for Different Carbide Grain Sizes,” Proceedings of 2014 Int’l Conference on Materials and Processing(ICMP2014), Paper No. ICMP2014-5043, Detroit, MI, USA, June 9-13, 2014.

C058. Stanley, C., Ulutan, D., Mears, L. (2014). “Prediction of Tool Wear Based on Cutting Forces when End Milling Titanium Alloy Ti-6Al-4V,” Proceedings of ASME 9thInternational Conference on Manufacturing Science and Engineering (MSEC2014), Paper No. MSEC2014-4140, Detroit, MI, USA, June 9-13, 2014.

C057. Ulutan, D., Pleta, A., Mears, L. (2014). “Multi-Objective Particle Swarm Optimization of Machining Parameters for End Milling Titanium Alloy Ti-6Al-4V,” Proceedings of ASME 9thInternational Conference on Manufacturing Science and Engineering (MSEC2014), Paper No. MSEC2014-4145, Detroit, MI, USA, June 9-13, 2014.

C056. Pleta, A., Ulutan, D., Mears, L. (2014). “Investigation of Trochoidal Milling in Nickel-Based Superalloy Inconel 738, and Comparison with End Milling,” Proceedings of ASME 9thInternational Conference on Manufacturing Science and Engineering (MSEC2014), Paper No. MSEC2014-4151, Detroit, MI, USA, June 9-13, 2014.

C055. Feng, L., Mears, L., Zhu, Q., Beaufort, C., Schulte, J. (2014). “Plant-Level Energy Supply Analysis and Optimization in Energy, Economy, and Environment,” Proceedings of 2014 ASME International Manufacturing Science and Engineering Conference (MSEC2014), Paper No. MSEC2014-4014, Detroit, MI, USA, June 9-13, 2014.

C054. Antani, K., Pearce, B., Mears, L., Renu, R., Kurz, E., Schulte, J. (2014). “System Learning for Manufacturing Process Planning,” Proceedings of ASME 9thInternational Conference on Manufacturing Science and Engineering (MSEC2014), Paper No. MSEC2014-3906, Detroit, MI, USA, June 9-13, 2014. (winner of ASME MSEC third place Best Paper Award)

C053. Pearce, B. Kurz, M. Antani, K., Mears, L. (2014). “Finding Maximum Subsets of Relational Objects using SAT Decomposition,” Proceedings of Institution ofIndustrial Engineers Annual Conference, Montréal, Canada, May 31-June 3, 2014, Paper No. 1987, pp. 2632-2638.

C052. Ulutan, D., Arisoy, Y.M., Özel, T., Mears, L. (2014). “Mathematical Modeling of Residual Stress Profile in Machining Nickel-Based Superalloys,” Proceedings of 2nd CIRP Conference on Surface Integrity, Nottingham, UK, 28th-30th May 2014.

C051. Ulutan, D., Pleta, A., Mears, L. (2014). “Modeling and Analysis of Residual Stresses after Machining a Nickel-Based Superalloy,” Proceedings of 3rd International Conference on Virtual Machining Process Technology (VMPT), Calgary, Alberta, Canada, May 20-23, 2014.

C050. Antani, K., Pearce, B., Kurz, E., Mears, L., Funk, K., Mayorga, M. (2013). “Manual Precedence Mapping and Application of a Novel Precedence Relationship Learning Technique to Real-World Automotive Assembly Line Balancing,” Proceedings of ASME 8thInternational Conference on Manufacturing Science and Engineering (MSEC2013), Paper No. MSEC2013-1235, Madison, WI, USA, June 10-14, 2013.

C049. Chen, Y., Milner, J., Bunget, C., Mears, L., Kurfess, T. (2013). “Investigations on Performance of Various Ceramic Tooling while Milling Nickel-Based Superalloys,”Proceedings of ASME 8thInternational Conference on Manufacturing Science and Engineering (MSEC2013), Paper No. MSEC2013-1220, Madison, WI, USA, June 10-14, 2013.

C048. Chen, Y., Bunget, C., Mears, L., Kurfess, T. (2013). “An Improved Empirical Constitutive Model for γ’-Strengthened Nickel-Based Superalloys,” Proceedings of 41st North American Manufacturing Research Conference (NAMRC41), Paper No. NAMRC41-1598, Madison, WI, USA, June 10-14, 2013.

C047. Henderson, A., Bunget, C., Mears, L., Kurfess, T. (2013). “Adaptive Tool Wear Estimation Using On-Machine Touch Probes,” Proceedings of 41st North American Manufacturing Research Conference (NAMRC41), Paper No. NAMRC41-1597, Madison, WI, USA, June 10-14, 2013.

C046. Jones, E., Jones, J., Mears, L., (2013). “Empirical Modeling of Direct Electric Current Effect on Machining Cutting Force,” Proceedings of ASME 8thInternational Conference on Manufacturing Science and Engineering (MSEC2013), Paper No. MSEC2013-1229, Madison, WI, USA, June 10-14, 2013.

C045. Jones, J., Mears, L., (2013). “Alternative Control of an Electrically-Assisted Tensile Forming Process Using Current Modulation,” Proceedings of ASME 8thInternational Conference on Manufacturing Science and Engineering (MSEC2013), Paper No. MSEC2013-1197, Madison, WI, USA, June 10-14, 2013.

C044. Mehta, P., Mears, L., (2013). “Model Learning in a Multistage Machining Process: Online Identification of Force Coefficients and Model Use in the Manufacturing Enterprise,” Proceedings of ASME 8thInternational Conference on Manufacturing Science and Engineering (MSEC2013), Paper No. MSEC2013-1144, Madison, WI, USA, June 10-14, 2013.

C043. Potluri, H., Jones, J., Mears, L., (2013). “Comparison of Electrically-Assisted and Conventional Friction Stir Welding Processes by Feed Force and Torque,” Proceedings of ASME 8thInternational Conference on Manufacturing Science and Engineering (MSEC2013), Paper No. MSEC2013-1192, Madison, WI, USA, June10-14, 2013.

C042. Mehta, P., Mears, L. (2012). “Cutting Force Control in Machining: Bayesian Update of Mechanistic Force Model,” Proceedings of the 5th Annual Dynamic Systems and Control Conference, Ft. Lauderdale, FL, USA, October 17-19, 2012.

C041. Antani, K., Madadi, A., Kurz, E., Mears, L., Mayorga, M., Funk, K. (2012). “Robust Work Planning And Development Of A Decision Support System For Work Distribution On A Mixed-Model Automotive Assembly Line,” Proceedings of ASME 7thInternational Conference on Manufacturing Science and Engineering (MSEC2012), Paper No. MSEC2012-7350, Notre Dame, IN, USA, June 10-13, 2012.

C040. Bunget, C., Salandro, W., Mears, L., (2012). “Sensitivities when Modeling Electrically-Assisted Forming,” Proceedings of ASME 7thInternational Conference on Manufacturing Science and Engineering (MSEC2012), Paper No. MSEC2012-7334, Notre Dame, IN, USA, June 10-13, 2012.

C039. Jones, J., Mears, L., (2012). “Thermal Response Characterization of Sheet Metals During Electrically-Assisted Forming (EAF),”Proceedings of ASME 7thInternational Conference on Manufacturing Science and Engineering (MSEC2012), Paper No. MSEC2012-7349, Notre Dame, IN, USA, June 10-13, 2012.

C038. Kuttolamadom, M., Mehta, P., Mears, L., Kurfess, T. (2012). “The Correlation of Volumetric Tool Wear & Wear Rate of Machining Tools with the Material Removal Rate of Titanium Alloys,”Proceedings of ASME 7thInternational Conference on Manufacturing Science and Engineering (MSEC2012), Paper No. MSEC2012-7338, Notre Dame, IN, USA, June 10-13, 2012.

C037. Mehta, P., Kuttolamadom, M., Mears, L., (2012). “Machining Process Power Monitoring: Bayesian Update of Machining Power Model,”Proceedings of ASME 7thInternational Conference on Manufacturing Science and Engineering (MSEC2012),Paper No. MSEC2012-7277, Notre Dame, IN, USA, June 10-13, 2012.

C036. Salandro, W., Bunget, C., Mears, L., (2012). “Modeling the Electroplastic Effect During Electrically-Assisted Forming of 304 Stainless,” Proceedings of ASME 7thInternational Conference on Manufacturing Science and Engineering (MSEC2012), Paper No. MSEC2012-7241, Notre Dame, IN, USA, June 10-13, 2012.

C035. Kuttolamadom, M., Jones, J., Mears, L., Kurfess, T., Funk, K. (2012). “Life-Cycle Integration of Titanium Alloys into the Automotive Segment for Vehicle Light-Weighting: Part II – Component Life-Cycle Modeling and Cost Justification,” Proceedings of Society of Automotive Engineers World Congress 2012, Paper No. 2012-01-0785.

C034. Jones, J., Kuttolamadom, M., Mears, L., Kurfess, T., Funk, K. (2012). “Life-Cycle Integration of Titanium Alloys into the Automotive Segment for Vehicle Light-Weighting: Part I – Component Redesign, Prototyping, and Validation,” Proceedings of Society of Automotive Engineers World Congress 2012, Paper No. 2012-01-0785.

C033. Montes, C., Ziegert, J., Wong, C., Mears, L. (2011). “Conditions and limitations of the low-bandwidth visual-servo loop in micro-positioning applications,” Proceedings of ASPE 2011 Annual Meeting, 52:173-176, Denver, CO, USA, November 13-18, 2011.

C032. Jones, J., Mears, L., (2011). “Constant-Current Density Compression Behavior of 304 Stainless Steel and Ti-6Al-4V During Electrically-Assisted Forming,” Proceedings of ASME 6thInternational Conference on Manufacturing Science and Engineering (MSEC2011), Paper No. MSEC-2011-50287, Corvallis, OR, USA, June 13-17, 2011.

C031. Kuttolamadom, M., Mears, L., (2011). “On the Volumetric Assessment of Tool Wear in Machining Inserts with Complex Geometries: Need, Methodology and Validation,” Proceedings of ASME 6thInternational Conference on Manufacturing Science and Engineering (MSEC2011), Paper No. MSEC-2011-50278, Corvallis, OR, USA, June 13-17, 2011.

C030. Martens, T., Mears, L., (2011). “Microfeature-Enhanced Sinter Bonding of Metal-Injection Molded (MIM) Parts to Solid Substrate,” Proceedings of ASME 6thInternational Conference on Manufacturing Science and Engineering (MSEC2011), Paper No. MSEC-2011-50129, Corvallis, OR, USA, June 13-17, 2011.

C029. Mehta, P., Mears, L., (2011). “Model-Based Prediction and Control of Machining Deflection Error in Turning Slender Bars,” Proceedings of ASME 6thInternational Conference on Manufacturing Science and Engineering (MSEC2011), Paper No. MSEC-2011-50154, Corvallis, OR, USA, June 13-17, 2011.

C028. Salandro, W., Bunget, C., Mears, L., (2011). “Thermo-Mechanical Investigations of the Electroplastic Effect,” Proceedings of ASME 6thInternational Conference on Manufacturing Science and Engineering (MSEC2011), Paper No. MSEC-2011-50250, Corvallis, OR, USA, June 13-17, 2011.

C027. Werner, A., Mears, L., Clark, A. (2011). “Dynamic Evaluation of a Nanocomposite Force Sensor,” Proceedings of ASME 6thInternational Conference on Manufacturing Science and Engineering (MSEC2011), Paper No. MSEC-2011-50059, Corvallis, OR, USA, June 13-17, 2011.

C026. Werner, A., Mehta, P., Mears, L., (2011). “Development of a Condition-Based Maintenance Program for a Computer-Numerically Controlled Machine: Signal Acquisition, Processing and Network Communication,” Proceedings of ASME 6thInternational Conference on Manufacturing Science and Engineering (MSEC2011), Paper No. MSEC-2011-50132, Corvallis, OR, USA, June 13-17, 2011.

C025. Montes, C., Wong, C., Ziegert, J., Mears, L., (2011). “Hybrid Command Issuing in a 2-Degree-of-Freedom Servomechanism Operated under Vision-Based Feedback Control,” Proceedings of 2011International Conference on Sustainable Automotive Technologies (ICSAT), Greenville, SC, USA, April 5-6, 2011.

C024. Dubey, M., Mears, L., Cannon, A., Hulseman, R. (2011). “Injection Mold Process Optimization for Surface Microfeature Control,” Proceedings of ASPE Spring Topical Conference, Charlotte, NC, USA,Paper No. 3222.

C023. Kuttolamadom, M., Jones, J., Mears, L., Ziegert, J., Kurfess, T. (2011). “A Systematic Procedure for Integrating Titanium Alloys as a Lightweight Automotive Material Alternative,” Proceedings of Society of Automotive Engineers World Congress 2011, Detroit, MI, April 12-14, 2011, Paper No. 2011-01-0429.

C022. Namouz, E., Mears, L., Mocko, G., Summers, J. (2011). “Lazy Parts Indication Method: Application to Automotive Components,” Proceedings of Society of Automotive Engineers World Congress 2011, Detroit, MI, April 12-14, 2011, Paper No. 2011-01-0428.

C021. Wong, C., Montes, C., Mears, L., Ziegert, J. (2010). “Model Based Control to Enhance a Novel Visual Control Positioning System,” Proceedings of International Conference on Control, Automation and Systems (ICCAS) 2010, Gyeonggi-do, Korea, Oct. 27-30, 2010.

C020. Montes, C., Ziegert, J., Wong, C., Mears, L., Tucker, T. (2010). “2-D Absolute Positioning System for Real-Time Control Applications,” Proceedings of the 2010 American Society for Precision Engineering Annual Meeting, Atlanta, GA, USA, September 13-15, 2010.

C019. Mears, L., Bunget, C., Salandro, W. (2010). “Tribological Aspects in Electrically-Assisted Forming,” Proceedings of ASME 5thInternational Conference on Manufacturing Science and Engineering (MSEC2010), Paper No. MSEC2010-34249, Erie, PA, USA, October 12-15, 2010.

C018. Jones, J., Mears, L. (2010). “A Process Comparison of Simple Stretch Forming Using Both Conventional and Electrically-Assisted Forming Techniques,” Proceedings of ASME 5thInternational Conference on Manufacturing Science and Engineering (MSEC2010), Paper No. MSEC2010-34144, Erie, PA, USA, October 12-15, 2010.

C017. Salandro, W., Bunget, C., Mears, L. (2010). “Modeling and Quantification of the Electroplastic Effect when Bending Stainless Steel Sheet Metal,” Proceedings of ASME 5thInternational Conference on Manufacturing Science and Engineering (MSEC2010), Paper No. MSEC2010-34043, Erie, PA, USA, October 12-15, 2010.

C016. McElreath, M., Mayorga, M., Mears, L. (2010). “Assigning Storage Locations in an Automated Warehouse,” Proceedings of Industrial Engineering Research Conference, Cancún, Mexico, 31 May – 3 June 2010.

C015. Morkos, B., Summers, J.D., Mears, L., Rilka, T., Taiber, J., Fadel, G. (2010). “Applicability Evaluation of Mobile Devices for Use Within Manufacturing Environments,” Proceedings of IDMME – Virtual Concept, Bordeaux, France, 1-8 June 2010.

C014. Vimalnathan, S., Mears, L. (2010). “Finite Element Simulation of Ring Rolling Process,” Proceedings of Society of Automotive Engineers World Congress 2010, Paper No. 2010-01-0270, Detroit, MI, USA, 13-15 April 2010.

C013. Kuttolamadom, M., Chorogudai, A., Mears, L., Kurfess, T.R. (2010). “Investigation of Machining of Titanium Components for Lightweight Vehicles,” Proceedings of Society of Automotive Engineers World Congress 2010, Paper No. 2010-01-0022, Detroit, MI, USA, 13-15 April 2010.

C012. Kuttolamadom, M., Hamzehlouia, S., Mears, L. (2010). “Effect of Machining Speed on Surface Roughness in Cutting 6061 Aluminum,” Proceedings of Society of Automotive Engineers World Congress 2010, Paper No. 2010-01-0218, Detroit, MI, USA, 13-15 April 2010 (reported also in SAE Special Publications book SP-2294, Advances In Light Weight Materials – Aluminum, Casting Materials, and Magnesium Technologies, 2010, ISBN 978-0-7680-3428-8).

C011. Martens, T., Mears , L., Dotson, M., Sanger , P., Graham, M. (2009). “Requirements Selection for Rapid Prototyping: Polyphenylsulfone as a Mold Material for Spin Casting Polyurethane Resin,” Proceedings of ASME 4thInternational Conference on Manufacturing Science and Engineering (MSEC2009), Paper No. MSEC2009-84361 West Lafayette, IN, USA, Oct. 4-7, 2009.

C010. Wong, C., Mears, L., Ziegert, J.C. (2009). “Dead Time Compensation for a Novel Positioning System via Predictive Control and Virtual Intermittent Setpoints,” Proceedings of ASME 4thInternational Conference on Manufacturing Science and Engineering (MSEC2009), Paper No. MSEC2009-84156, West Lafayette, IN, USA, Oct. 4-7, 2009.

C009. Burger, U., Kuttolamadom, Bryan, A., M., Mears, L., Kurfess, T.R. (2009). “Volumetric Flank Wear Characterization for Titanium Milling Insert Tools,” Proceedings of ASME 4thInternational Conference on Manufacturing Science and Engineering (MSEC2009), Paper No. MSEC2009-84256, West Lafayette, IN, USA, Oct. 4-7, 2009.

C008. Grubb, M., Berger, A., Browning, D., Mayorga, M., Mears, M.L. (2009). “WARNING! Engineers in Training.” May 2009, IIE Annual Conference and Expo 2009, Miami, FL, USA.

C007. Teppa, S., Mears, L. (2009). “Bonding Strength Modeling of Polyurethane to Vulcanized Rubber,” Proceedings of Society of Automotive Engineers World Congress 2009, Paper No. 2009-01-0605, Detroit, MI, USA, 20-23 April 2009.

C006. Chimalapati, S., Mears, L., Clark, A. (2008). “Characterization of a Nanocomposite Force Sensor in Multiple Environmental Domains,” Proceedings of ASME 3rd International Conference on Manufacturing Science and Engineering (MSEC2008), Paper No. MSEC_ICMP2008-72503,Evanston, IL, USA, October 7-10, 2008.

C005. Wong, C., Montes, C., Mears, L., Ziegert, J. (2008). “A New Position Feedback Method for Manufacturing Equipment,” Proceedings of ASME 3rd International Conference on Manufacturing Science and Engineering (MSEC2008), Paper No. MSEC_ICMP2008-72222, Evanston, IL, USA, October 7-10, 2008.

C004. Roth, J. T., Mears, L., et al. (2007). “Quality and inspection of machining operations: Review of condition monitoring and CMM inspection techniques 2000 to present.” Proceedings of ASME 2ndInternational Conference on Manufacturing Science and Engineering (MSEC2007), Paper No. MSEC2007-31221, Atlanta, GA, USA, October 15-18, 2007.

C003. Mears, L., Falcon, J. (2007). “Real-Time System Identification for Impact-Based Part Positioning.” International Conference on Smart Machining Systems, National Institute of Standards and Technology, Gaithersburg, MD, USA, March 13-15, 2007.

C002. Mears, L., Falcon, J., Kurfess, T. (2006). “Real-Time Identification of Sliding Friction Using LabVIEW FPGA.”Proceedings of the 2006 American Control Conference, Minneapolis, MN, USA,June 14-16, 2006, ACC2006: 1410-1415.

C001. Mears, L., Kurfess, T. (2005). “Design of a Flexible and Agile Centering Preprocessing System.” Proceedings of the 2005 International Conference on Agility (ICAM 2005), Int’l Soc. of Agile Manufacturing, Helsinki, Finland, July 27-28, 2005: 307-313. (winner of conference Best Presentation Award)

News

Harshada wins Sage Fellowship

Congratulations to Harshada for winning the Sage Fellowship in Automotive Engineering!

Congratulations Tyler at IMECE

Tyler presented 3 papers and a poster at the 2019 ASME IMECE Conference, and was awarded Honorable Mention for the Best Paper Award of the [...]

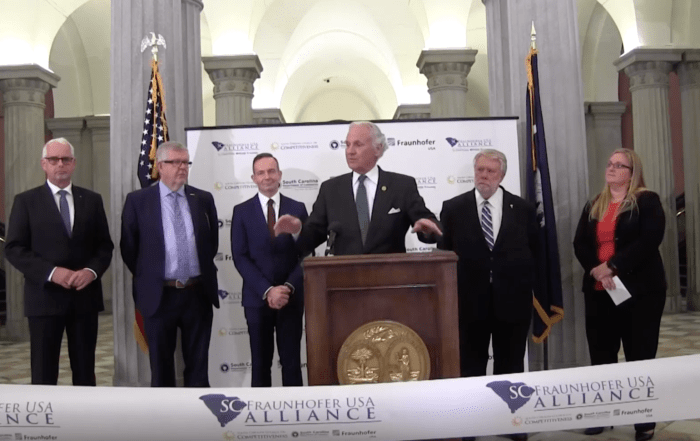

Governor McMaster Launches Fraunhofer Alliance

Governor McMaster held the ribbon cutting for the new Fraunhofer Alliance in South Carolina. We have been working with UofSC for 3 years on designing [...]