Human Integration to the Internet of Things

The scientific theme of this research program is investigating connecting the human element with the emerging digital manufacturing enterprise (i.e., Industrial Internet of Things), quantifying physical and mental human behaviors and their uncertainty, and investigating the effect of human-integrated digital technologies as both information generators and feedback mechanisms on attitudes and performance in the manufacturing enterprise.

The objectives are to first understand the quality of information that becomes available through human-based data capture and analysis technologies, including uncertainty distributions, then investigate means of feeding back digital information to human agents in order to assess the effect on human performance and the overall manufacturing system metrics.

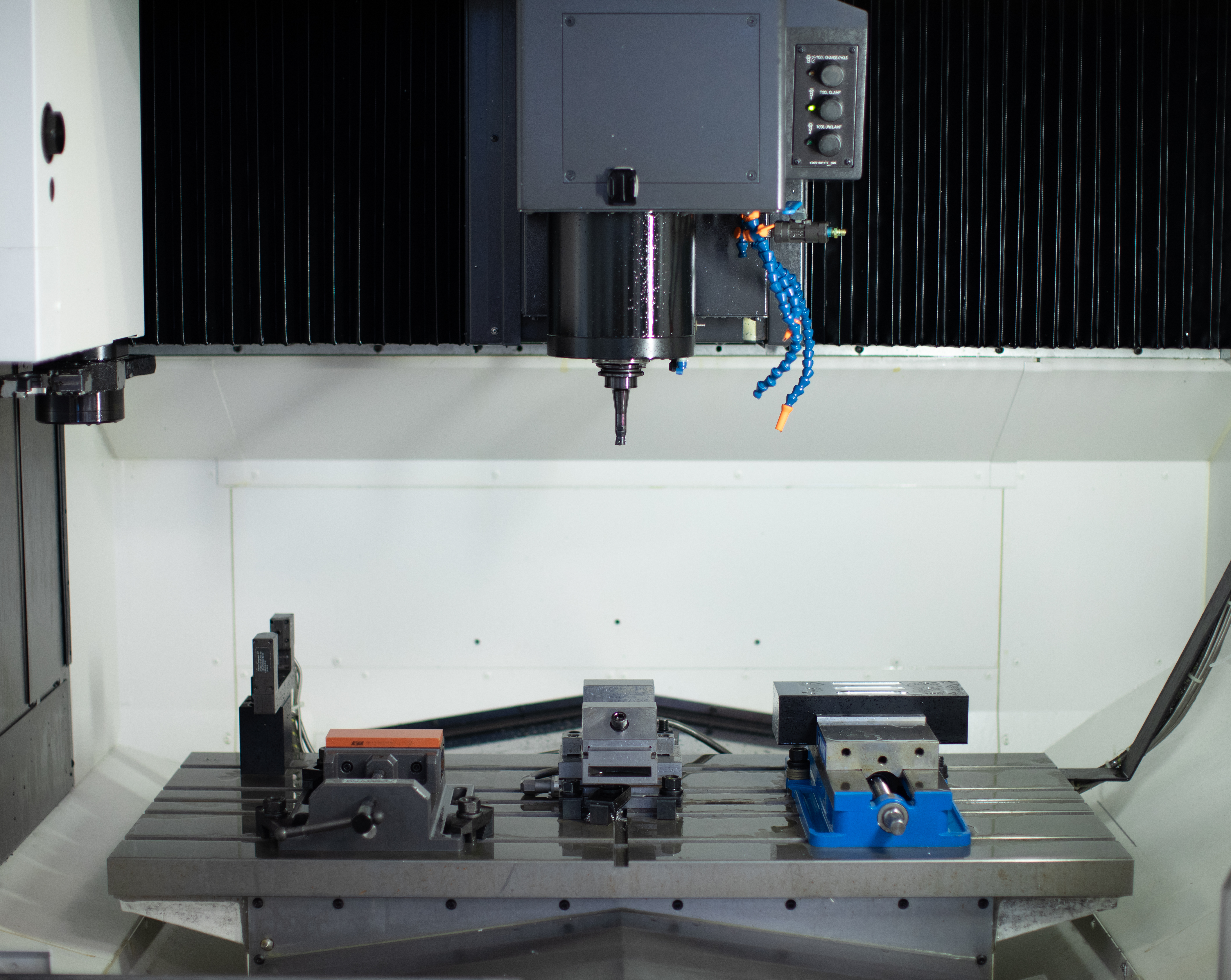

Energy-Assisted Forming and Joining

This research addresses limitations of current forming, machining, and joining processes through energy augmentation. Electric current supply is incorporated to equipment and fixture designs, and controls developed to actively modulate metallic material properties during processing. Results are the ability to process thicker, stronger materials at a higher rate with improved quality control.

Research Philosophy

The SmartState Lab’s research centers on estimation of manufacturing process states and the inclusion of physical and phenomenological models of manufacturing processes to process control. In exploring this line, I focus on control of processes, control of systems, associated sensing to gather system information, and development of new processes.

A key area of interest under this theme is in integrating the human element to the emerging Internet of Things. Novel sensors, feedback systems, and signal and image processing approaches can effectively make the human part of the control loop of manufacturing, rather than an external observer.

Finally, the lab uses data and models from experimentation to understand limitations of a process and how that restricts the ability of designers to be creative. We initiated in 2013 the Manufacturing for Design methodology, which essentially uses product designer creativity to motivate new approaches in manufacturing. This has led to process augmentation such as Energy-Assisted Manufacturing, and new assembly architectures.