SmartState Machining Research

Stochastic Milling

Conventional machining consists of steady-state cuts, which allow chatter to build up and resists permissible depth and speed, and therefore material removal rate. Stochastic toolpath consists of continuous circular arcs; this toolpath reduces chatter by randomly changing the directions of cutting forces to avoid resonance. The Stochastic toolpaths are longer than the conventional toolpaths; however, a decrease in chatter permits higher feeds and speeds and increases the material removal rate.

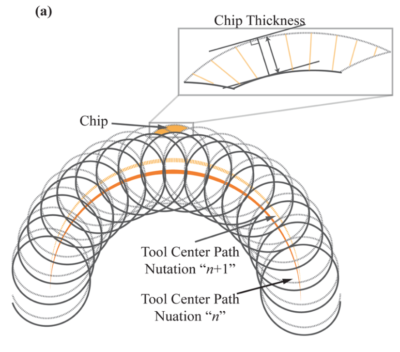

Trochoidal Milling

A rotating element superimposed with linear motion is simple to describe, however calculation of the set of intersection points of such curves is a surprisingly intractable problem.

Such paths applied to metal cutting produce stable paths with highly-predictable tool wear and some very interesting properties at certain combinations of parameters. Our lab works on efficient calculation of chip geometries and studies the benefits of these applications. ?

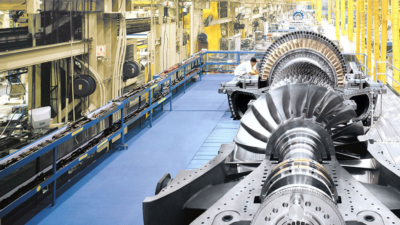

Nickel-Based Superalloy Machining

These materials are used extensively in the aerospace and energy industries. There, newer materials are designed to withstand higher and higher temperatures and stresses, so they become more and more difficult to cut!

Our lab studies how these difficult-to-machine materials respond to different machine tool control approaches and tool geometries, materials, and paths. ?

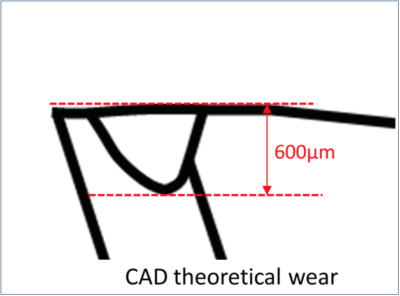

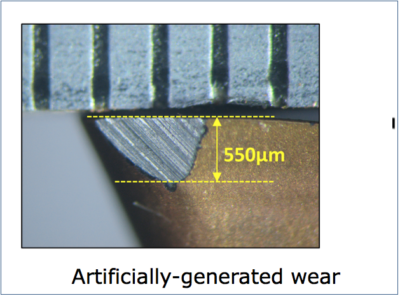

Controlled Tool Wear Investigation

A unique aspect to our experimental investigation is our approach termed contrived tool wear. With this approach, the nominal wear shape under a given set of conditions is ground into a new set of cutting tools, so that the repeatability of phenomenological models is decoupled from the process variability.

Through this approach, we gain insight into the force, machining affected zone, and stability progression independent from the tool wear variability. ?